G-code is a fundamental aspect of CNC (Computer Numerical Control) machining, serving as the language that CNC machines use to understand and execute various tasks. This article provides a comprehensive overview of G-code, its importance in CNC machining, common commands, and how it contributes to the precision and efficiency of manufacturing processes. By understanding G-code, manufacturers can better utilize CNC technology to produce high-quality components.

What Is G-Code?

G-code, or “Geometric Code,” is a programming language used to control CNC machines. It consists of a series of commands that instruct the machine on how to move its tools, including the direction, speed, and path of the movements. G-code is the bridge between computer-aided design (CAD) models and the physical machining process, translating digital designs into precise, automated actions.

Importance of G-Code in CNC Machining

- Precision and Accuracy

- Exact Movements: G-code allows for highly precise control over the movements of CNC machine tools, ensuring that parts are manufactured to exact specifications.

- Consistent Quality: Automated execution of G-code commands results in consistent quality across multiple parts, reducing variability and errors.

- Efficiency and Productivity

- Automated Operations: G-code enables CNC machines to perform complex tasks automatically, increasing production speed and efficiency.

- Reduced Manual Intervention: Once programmed, G-code reduces the need for manual adjustments, freeing up operators to focus on other tasks.

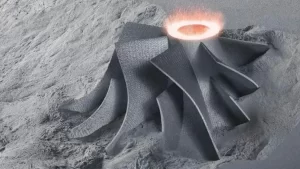

- Complex Geometries

- Intricate Designs: G-code can control multiple axes simultaneously, allowing the creation of complex geometries that would be challenging or impossible with manual machining.

- 3D Machining: Enables three-dimensional machining, essential for industries like aerospace, automotive, and medical device manufacturing.

Common G-Code Commands

- Movement Commands

- G00: Rapid positioning. Moves the machine’s tool to a specified location at maximum speed.

- G01: Linear interpolation. Moves the tool in a straight line at a specified feed rate.

- G02/G03: Circular interpolation. Moves the tool in a clockwise (G02) or counterclockwise (G03) arc.

- Tool Commands

- M06: Tool change. Instructs the machine to change the current tool.

- M03/M04: Spindle control. M03 starts the spindle clockwise, and M04 starts it counterclockwise.

- M05: Stops the spindle.

- Setting Commands

- G20/G21: Units selection. G20 sets units to inches, and G21 sets units to millimeters.

- G90/G91: Positioning mode. G90 sets absolute positioning, and G91 sets incremental positioning.

- G92: Set position. Assigns a specific coordinate value to the current tool position.

- Auxiliary Commands

- M00: Program stop. Temporarily halts the program until the operator resumes it.

- M30: Program end. Ends the program and resets the machine to the start position.

- M08/M09: Coolant control. M08 turns the coolant on, and M09 turns it off.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

How G-Code Contributes to Manufacturing

- Optimized Machining

- Path Optimization: G-code programs can be optimized to minimize tool movement, reducing machining time and wear on the tools.

- Adaptive Machining: Advanced G-code programming can include adaptive strategies that adjust machining parameters in real-time based on tool wear or material variations.

- Simulation and Testing

- Program Verification: G-code can be simulated using CAM (Computer-Aided Manufacturing) software to verify the program’s accuracy and efficiency before actual machining.

- Error Detection: Simulations help detect potential errors or collisions, preventing costly mistakes during production.

- Flexibility and Customization

- Custom Programs: G-code allows for the creation of custom machining programs tailored to specific parts or processes.

- Parameter Adjustments: Operators can adjust G-code parameters on the fly to fine-tune machining operations for optimal results.

Future Trends in G-Code and CNC Machining

- Advanced CAM Software

- Automated G-Code Generation: Modern CAM software can automatically generate optimized G-code from CAD models, simplifying the programming process.

- AI Integration: Artificial intelligence is being integrated into CAM software to enhance G-code generation and optimize machining parameters.

- Enhanced Connectivity

- IoT and Industry 4.0: Connecting CNC machines to the Internet of Things (IoT) enables real-time monitoring, data collection, and predictive maintenance.

- Cloud-Based Solutions: Cloud-based platforms allow for remote programming, monitoring, and control of CNC machines, increasing flexibility and efficiency.

- Sustainability and Efficiency

- Energy-Efficient Machining: Development of energy-efficient CNC machines and programming techniques to reduce power consumption and operational costs.

- Green Manufacturing: Adoption of eco-friendly practices and materials to minimize the environmental impact of CNC machining.

Conclusion

G-code is the backbone of CNC machining, enabling precise, efficient, and automated manufacturing processes. Understanding G-code commands and their applications is crucial for optimizing CNC operations and achieving high-quality results. As technology continues to evolve, advancements in CAM software, connectivity, and sustainability will further enhance the capabilities and efficiency of CNC machining.

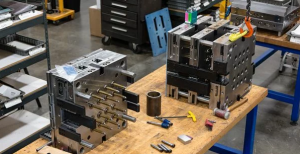

Related Conten: CNC Mold Manufacturing