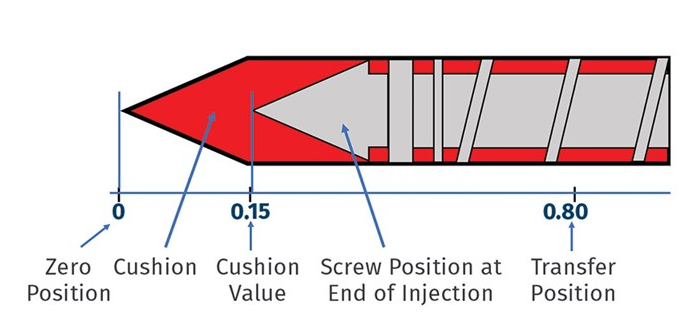

In injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in the barrel of the injection molding machine at the end of the injection phase. This cushion is maintained to ensure consistent pressure and proper filling of the mold cavity during the entire injection cycle.

Key Aspects of Cushion in Injection Molding

- Definition and Purpose

- Cushion: The cushion is the remaining volume of molten plastic in the barrel after the injection screw has completed its forward movement to fill the mold cavity.

- Purpose: The primary purpose of maintaining a cushion is to ensure that there is sufficient material to compensate for any pressure loss or material shrinkage during the packing and holding phases. This helps in achieving consistent part quality and dimensional accuracy.

- Function During the Molding Cycle

- Injection Phase: During the injection phase, the screw moves forward to push the molten plastic into the mold cavity. As the screw reaches the end of its stroke, a small volume of molten plastic is left in the barrel, forming the cushion.

- Packing and Holding Phase: During these phases, the cushion allows the machine to apply additional pressure to pack the material into the mold and compensate for material shrinkage as it cools and solidifies. This ensures that the mold cavity is completely filled and that the part has the correct dimensions and minimal internal stresses.

- Importance of Proper Cushion

- Consistent Pressure: A properly maintained cushion ensures that the pressure applied during the packing and holding phases remains consistent from cycle to cycle, leading to uniform part quality.

- Preventing Short Shots: If the cushion is too small or nonexistent, there may not be enough material to completely fill the mold cavity, resulting in short shots (incomplete parts).

- Avoiding Overpacking: If the cushion is too large, it can lead to overpacking, where too much material is forced into the mold cavity, causing excessive stress, flash, or other defects.

- Adjusting Cushion Size

- Monitoring and Adjustment: The cushion size can be monitored and adjusted through the injection molding machine’s control system. It is typically measured in millimeters or inches of screw travel.

- Optimization: The optimal cushion size depends on the specific material being used, the part geometry, and the molding conditions. Typically, a cushion size of 3-6 mm (0.12-0.24 inches) is considered appropriate, but this can vary based on specific requirements.

Potential Issues with Cushion

- Too Small Cushion

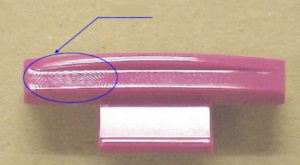

- Pressure Loss: A cushion that is too small can result in a loss of packing pressure, leading to incomplete filling, sink marks, or voids in the part.

- Process Inconsistency: Insufficient cushion can cause variability in the molding process, resulting in inconsistent part quality.

- Too Large Cushion

- Overpacking: A large cushion can lead to overpacking, causing flash (excess material) around the parting line and other dimensional inaccuracies.

- Machine Wear: Excessive cushion may put unnecessary stress on the machine components, potentially leading to increased wear and maintenance requirements.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Conclusion

The cushion in injection molding is a critical parameter that ensures consistent pressure during the packing and holding phases, leading to high-quality, dimensionally accurate parts. Proper management of the cushion size helps prevent defects such as short shots and overpacking, contributing to a stable and efficient injection molding process. Adjusting and optimizing the cushion size based on material properties and part requirements is essential for achieving optimal results in injection molding production.

Related Conten: Custom Plastic Fabrication / Rapid Injection Molding