Introduction

In today’s world, where personal protection and workplace safety are top priorities, PPE injection molding plays a critical role in delivering high-quality protective gear at scale. This process not only enhances the durability of safety products but also ensures cost-efficiency and regulatory compliance.

What Is PPE Injection Molding?

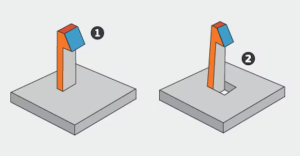

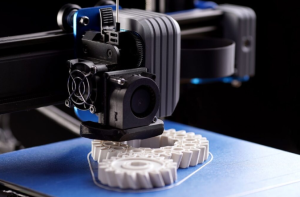

PPE injection molding is a manufacturing process used to produce personal protective equipment (PPE) from thermoplastic materials. The method involves melting plastic pellets, injecting them into a custom mold, and allowing them to cool and solidify into the desired shape. Common PPE items made through injection molding include face shields, respirator components, protective goggles, and helmet shells.

Key Advantages of PPE Injection Molding

1. Precision and Consistency

Injection molding ensures that each PPE product is produced to exact specifications. This consistency is vital for items that must meet strict safety standards.

2. High Volume Production

The process is ideal for mass production. Once a mold is made, thousands of identical items can be produced rapidly, making it ideal for industries needing a large and reliable PPE supply.

3. Material Versatility

ABS, polypropylene, and polycarbonate are commonly used in PPE injection molding, offering flexibility, impact resistance, and lightweight properties — all critical for comfortable, long-lasting protective gear.

4. Cost Efficiency Over Time

Though initial mold creation can be costly, long-term production becomes highly economical. This is particularly beneficial for companies producing standard safety equipment at scale.

5. Regulatory Compliance

PPE produced via injection molding is easier to standardize, helping manufacturers adhere to health and safety regulations such as OSHA or CE certification requirements.

Applications in Safety Product Manufacturing

PPE injection molding supports various industries:

Healthcare: Face shields, mask components

Construction: Hard hats, safety goggles

Industrial Workplaces: Respirators, visors

Laboratories: Eye and face protection gear

With the ability to customize molds and choose advanced materials, manufacturers can develop ergonomic, lightweight, and highly protective products tailored to specific work environments.

Future Trends in PPE Injection Molding

Advancements in material science and automation are shaping the next generation of PPE. Bio-based plastics, antimicrobial additives, and automated mold monitoring systems are just a few innovations driving sustainability and performance in PPE production.