Home » Case Products » Unlock Precision and Efficiency with Scientific Injection Molding

Unlock Precision and Efficiency with Scientific Injection Molding

At DTG Injection Molding, we take your production to the next level with our expertise in scientific injection molding. Our advanced, data-driven approach ensures that every part we produce meets the highest standards of quality, consistency, and efficiency.

Why Choose DTG Injection Molding for Scientific Injection Molding?

1. Data-Driven Precision: Scientific injection molding uses advanced analytical techniques to control every aspect of the molding process. We employ precise measurements and real-time data to fine-tune variables such as temperature, pressure, and material flow, resulting in exceptional part accuracy and consistency.

2. Superior Part Quality: Our scientific approach minimizes defects and variability, leading to high-quality parts with optimal performance. By understanding and controlling the molding process, we ensure that each component meets stringent quality standards.

3. Enhanced Efficiency: Our data-driven methods streamline the production process, reducing cycle times and material waste. This not only cuts down costs but also accelerates time-to-market, allowing you to launch your products faster.

4. Custom Molding Solutions: We tailor our scientific molding techniques to your specific project needs. Whether you require complex designs or high-precision components, our approach adapts to deliver custom solutions that meet your exact requirements.

5. Consistent Results: Scientific injection molding ensures uniformity across all parts produced. Our rigorous process controls guarantee that every batch maintains the same high level of quality, providing reliability and predictability in your production.

6. Continuous Improvement: We leverage ongoing data analysis to continually refine and optimize the molding process. This commitment to improvement enhances both the quality and efficiency of your production, giving you a competitive edge.

7. Expert Guidance: Our team of experts provides comprehensive support throughout the molding process. From initial design to final production, we offer valuable insights and recommendations to ensure that your project is executed flawlessly.

Discover the Advantages of Scientific Injection Molding with DTG Injection Molding

Transform your manufacturing process with our advanced scientific injection molding services. Contact DTG Injection Molding today to learn how our precision-driven approach can enhance your production quality and efficiency.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Multi Shot Injection Molding

Read more -

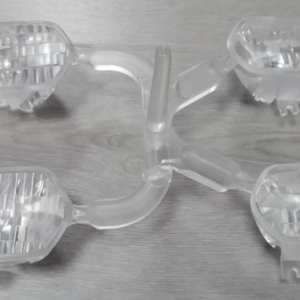

Optical Injection Molding: Precision Molding for High-Performance Optical Components

Read more -

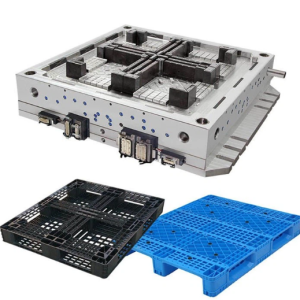

Injection Molded Plastic Pallets

Read more -

Innovate with Injection Foam Molding from DTG Injection Molding

Read more -

Transform Your Concepts with Expert Injection Mold Prototypes

Read more -

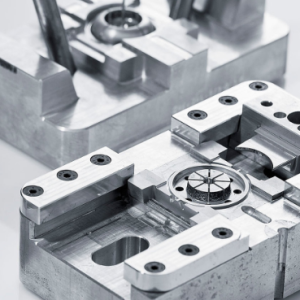

Custom Injection Molds: Precision Solutions for Your Manufacturing Needs

Read more