Home » Case Products » Custom RV Air Vent Cover – White Motorhome Vent

Custom RV Air Vent Cover – White Motorhome Vent

Product Overview: A Durable, Clean-Look RV Air Vent Cover Made for OEM and MRO Buyers

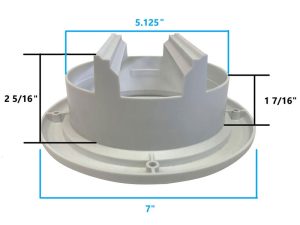

This RV Air Vent Cover is a two-piece, injection-molded assembly designed for roof or ceiling ventilation in motorhomes, travel trailers, and fifth wheels. The set includes a mounting ring with countersunk screw bosses and a removable louvered grille that snaps in for quick service. Its neutral white finish blends with most RV interiors, making it an ideal White Vent for Motorhome Roof or ceiling return/supply point.

From the supplied dimensions, typical specs include: 7.0″ outer flange diameter, ≈5.125″ duct/opening size, ≈2-5/16″ overall height, and ≈1-7/16″ ring depth—a compact footprint that fits common RV ducts while providing robust airflow. The grille ribs are evenly spaced for smooth air diffusion and easy dust wipe-down. Four mounting holes simplify alignment and reduce installation time.

Built for OEM production and aftermarket replacement, this Motorhome Plastic Vent delivers the durability, consistency, and aesthetic finish you expect from professional plastic injection molding.

Functions & Design: Clean Airflow, Moisture Control, and Odor Defense

Air circulation. The louvered grille supports balanced intake or supply, making it suitable as an RV Air Conditioning Vent for both AC distribution and general ventilation. The laminar louver layout reduces turbulence and whistling at typical fan speeds.

Moisture venting. In galleys and bathrooms, venting helps exhaust humidity, limiting condensation that can damage cabinets, headliners, and insulation.

Odor mitigation. Proper airflow across the living space sweeps out stale air and cooking odors. The removable grille lets maintenance teams vacuum or wash debris to keep ducts clean.

Design features.

-

UV-stabilized white finish to resist yellowing under skylight exposure.

-

Impact-resistant, heat-tolerant resin (ABS/PP/PC-ABS options) suitable for RV interior temperatures.

-

Countersunk screw bosses for flush mounting and a neat aesthetic.

-

Snap-fit louver insert for tool-free servicing and filter access.

-

Smooth radii and closed-cell surfaces reduce dust traps and simplify cleaning.

-

Optional foam gasket to improve seal and reduce ceiling swirl marks.

Together, these features deliver a clean look, reliable airflow, and long service life—the core expectations of B2B buyers in the RV segment.

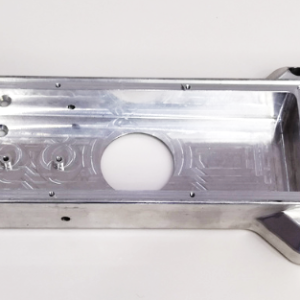

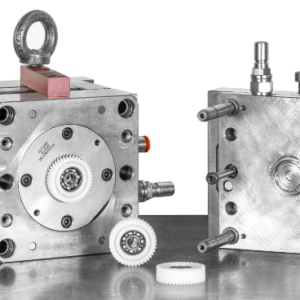

Manufacturing Process: How DTG Builds Quality into Every Vent

DTG specializes in Custom Mold & Injection Molding Production for automotive and RV components. Below is the typical process we follow to manufacture this RV Air Vent Cover with repeatable quality.

1) Mold design & manufacturing

Our engineers generate a DFM (Design for Manufacturability) report covering parting lines, draft angles (commonly ≥1° on the ribs and ring), gate locations, ejection strategy, wall-thickness uniformity (to prevent sink at the screw bosses), and tolerance stack-ups. We design steel tooling with hardened inserts around the snap-fit features and bosses for longevity in mass production.

2) Material selection & preparation

We recommend UV-stabilized ABS for stiffness and cosmetic finish, or PP for chemical resistance and lower density. Where heat and impact are critical (near appliances), PC-ABS can be specified. Resin lots are dried to manufacturer specs to prevent splay and maintain consistent mechanical properties and color.

3) Injection molding

We run process windows matched to the material—barrel temperatures, injection/holding pressures, and cooling time optimized to control warpage on the flat mounting flange. Balanced multi-cavity molds drive volume efficiency while maintaining identical flow length and packing across cavites.

4) Cooling & ejection

Conformal or optimized cooling channels around the boss and snap-fit areas reduce cycle time and deformation. Ejector placement is tuned to avoid blush marks on visible faces.

5) Deflashing, surface finish & assembly

Gates are trimmed flush. We can supply a matte cosmetic finish via mold texturing to hide fingerprints and minor scuffs. The grille and ring are checked for snap-fit force within spec so technicians can remove and reinstall without tool damage.

6) Quality inspection

Each batch undergoes dimensional checks (CMM/Go-NoGo), pull/torque tests on screw bosses, snap-fit cycle tests, and UV exposure sampling where required. PPAP/FAI documentation is available for OEM programs. Results are logged for traceability.

This closed-loop workflow ensures the vent you receive meets engineering intent, cosmetic expectations, and long-term durability targets.

Customization: Tailored Motorhome Plastic Vent Solutions

Every RV platform is different. DTG supports custom geometry and branding so your vents integrate perfectly.

-

Sizes & interfaces. Adjust ring depth, duct ID (e.g., 4″, 5″, 6″), and flange diameter.

-

Louver styles. Choose fixed or adjustable louvers, angled vanes to direct flow, or honeycomb diffusers for ultra-quiet supply.

-

Filtration. Add snap-in mesh screens or thin washable pre-filters.

-

Materials & colors. Standard white, warm white, black, or custom Pantone matches; UL94 V-0/5VA grades on request.

-

Logos & markings. Molded brand marks or laser codes for inventory and warranty tracking.

-

Mounting options. Self-tapping screw bosses, quarter-turn bayonets, or concealed clips for a seamless appearance.

For design transfers, send CAD files, target airflow/pressure drop, and environmental constraints. We’ll collaborate on DFM and prototype iterations until the part meets your functional and aesthetic targets.

Quality Standards: Built to OEM Expectations

-

Dimensional stability: process capability studies (Cp/Cpk) on critical IDs/ODs and flatness.

-

Mechanical integrity: boss pullout, snap-fit fatigue, and elevated-temp creep checks.

-

Appearance: ΔE color tolerance against master chips; gate/knit line quality criteria on A-surfaces.

-

Reliability: UV and thermal cycling for roof or near-roof installations; chemical wipe tests for cleaners.

-

Documentation: PPAP, IMDS (when automotive-grade materials are used), and RoHS/REACH compliance.

The outcome is a Motorhome Plastic Vent aligned with industry standards and the daily realities of RV use.

Market Needs & Pain Points: What B2B Buyers Want

RV OEMs and service networks focus on parts that are durable, cost-effective, and consistent across builds. Typical procurement criteria include:

-

Fit consistency to avoid rework on assembly lines.

-

Stable lead times to match production schedules and seasonal surges.

-

Total cost advantages without compromising appearance.

-

Warranty peace of mind backed by test data and traceability.

-

Supplier reliability for multi-year programs and model refreshes.

Injection molding advantages. Once tooling is validated, injection molding delivers tight tolerances, excellent cosmetics, and rapid cycle times, making it ideal for both mass production and low volume injection molding runs for service parts or mid-cycle updates. With DTG’s process control, you reduce scrap, simplify installation, and lower total landed cost.

Why DTG: Your Injection Molding Partner for RV Air Vents

One-stop service. We provide the complete path from mold manufacturing and prototype development to plastic injection molding and logistics, minimizing supplier handoffs and communication risk.

Flexible capacity. Whether you need low volume injection molding (short runs, pilot builds, or MRO kits) or mass production, our cell layout and cavity strategy scale with your demand.

High precision & quality control. Our mold engineers control every detail—gate location, cooling, venting, and texturing—so the part you approve is the part you receive throughout the program. Statistical process control and first-article inspections guard quality at launch and beyond.

The DTG Process (at a glance).

-

QUOTE PHASE: We gather CAD, materials, drawings, and quantities; if you need design support, our plastic design team assists.

-

MOLD DESIGN & CREATION: You review a DFM; on approval, we cut the tool and run T1 samples with reports for your sign-off; we also complete our internal first article.

-

PRODUCTION: After your approval, we procure resin and schedule molding; parts are packed and labeled per your work instructions.

-

LOGISTICS & DELIVERY: We consolidate shipments and deliver within agreed timelines, globally.

This structured flow de-risks launches, keeps milestones visible, and shortens time to revenue.

Real-World Results: Case Snapshots & Testimonials

RV OEM ventilation upgrade (North America). An OEM needed a white ceiling vent with tighter flatness on the flange to seal against lightweight composite headliners. DTG re-balanced cooling and added localized steel for a flatter part. Result: 45% reduction in installation rework and improved cosmetic scores in dealer audits.

Service network retrofit. A West-coast service group required low volume injection molding for retrofit kits (few hundred sets per quarter). DTG kept the original mold but produced a dedicated color-matched batch each month, reducing their on-hand inventory by 30% while maintaining next-day ship from our warehouse.

What buyers say.

-

“Fit and finish are consistent, and the snap-in grille is technician-friendly.”

-

“DTG’s DFM saved us a tooling revision and weeks on the calendar.”

-

“We get clear communication on lead times—no surprises in peak season.”

Technical Highlights & Options

-

Nominal dimensions: 7.0″ flange OD; ≈5.125″ duct interface; ≈2-5/16″ total height; ≈1-7/16″ ring depth.

-

Materials: ABS (standard), PP (chemical resistance), PC-ABS (impact/heat), with UV packages.

-

Color: White standard; custom tones on request.

-

Mounting: 4-hole screw pattern; alternative clip/bayonet available.

-

Accessories: Seal gaskets, mesh screens, thin pre-filters, branded caps.

-

Compliance: RoHS/REACH; optional UL94 flame ratings.

Installation & Maintenance (for end users and MRO teams)

-

Remove the old grille and ring; clean the surface.

-

Align the new ring and fasten with appropriate screws (avoid over-torque).

-

Snap in the louvered grille.

-

Run the fan to verify airflow and listen for noise; adjust if using an adjustable-louver option.

-

For maintenance, pop the grille out, vacuum dust, and reinstall—no specialized tools required.

FAQ

Q1: Is this vent suitable as an RV Air Conditioning Vent or only for passive airflow?

A: It works for both. The louver geometry diffuses supply air and also serves as an intake/return. For high-CFM applications, ask us about vane angles optimized for your static pressure.

Q2: Can DTG support low volume injection molding for service parts?

A: Yes. We routinely run small batches for service networks and retrofit kits, then scale to mass production for OEM programs using the same validated tooling.

Q3: What materials do you recommend for roof-adjacent locations with strong sunlight?

A: UV-stabilized ABS is the most common. For higher heat or impact needs, PC-ABS is available. All options can be supplied in white to match your interior.

Q4: Can we add branding or a custom color?

A: Absolutely. We can mold logos, add discrete marks for part tracking, and color-match to Pantone/RAL chips to maintain a consistent brand palette.

Conclusion & Call to Action

DTG’s RV Air Vent Cover brings together clean design, proven injection-molded durability, and configurability for both OEM builds and aftermarket programs. With expert DFM, robust tooling, and flexible capacity—from low volume injection molding pilot runs to mass production—we help B2B buyers cut total cost, stabilize lead times, and raise customer satisfaction.

Ready to spec a Motorhome Plastic Vent that fits perfectly and ships on time? Contact DTG today for a fast DFM review, T1 sampling plan, and a production quote.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Metal Prototyping Services: Precision and Durability for Advanced Product Development

Read more -

Prototype Tooling Plastics: High-Quality Prototypes for Rapid Development

Read more -

Aluminum Prototyping: Precision, Strength, and Speed for Your Product Development

Read more -

Custom Plastic Molding for Plastic Motor End Cap

Read more -

Custom Automotive Original Plastic Fittings Service

Read more -

Insert Molding Injection: Enhance Your Product with Integrated Solutions

Read more