Home » Case Products » 3D Printer Injection Molding: Combining Additive Manufacturing with Precision Molding for Innovative Solutions

3D Printer Injection Molding: Combining Additive Manufacturing with Precision Molding for Innovative Solutions

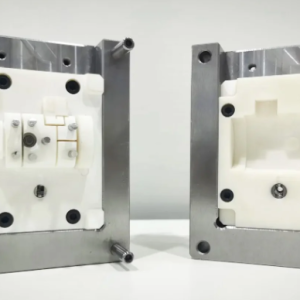

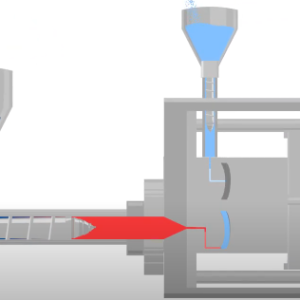

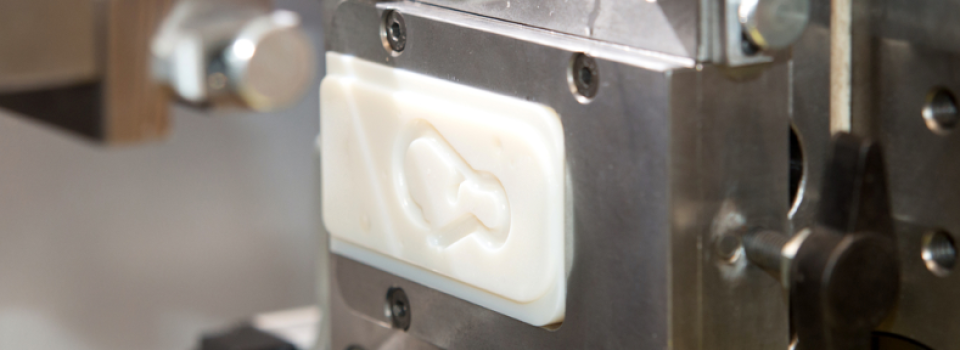

Revolutionize your production process with our 3D printer injection molding services, seamlessly integrating the flexibility of 3D printing with the precision and efficiency of traditional injection molding. This hybrid approach allows for rapid prototyping, design validation, and cost-effective production of complex components, perfect for industries like automotive, medical devices, and consumer electronics.

Why choose our 3D printer injection molding services?

- Rapid Prototyping: Quickly create and test prototypes using 3D printing before moving to injection molding for mass production, reducing development time and costs.

- Complex Designs: Achieve intricate and detailed parts that are difficult or impossible to produce with traditional methods alone, thanks to the design freedom of 3D printing.

- Cost-Effective Production: Minimize material waste and tooling costs by using 3D printed molds for short-run production, ideal for small batches or customized products.

- Flexible Material Options: Access a wide range of thermoplastics and advanced materials, ensuring that your parts meet specific performance and aesthetic requirements.

- Seamless Transition: Effortlessly move from prototype to production with our integrated approach, ensuring consistency in quality and design from start to finish.

Leverage the power of 3D printer injection molding to innovate and streamline your product development process. Contact us today to explore how our services can provide you with high-quality, precision-engineered components tailored to your exact needs.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Custom Design Plastic Manufacturing Mould Plastics Parts for Mechanical Handles

Read more -

Custom OEM Plastic for Electric Appliance Parts

Read more -

Innovative 3D Printed Injection Mold Solutions

Read more -

Multi Shot Plastic Injection Molding

Read more -

Comprehensive Guide to Injection Molding Materials

Read more -

Custom Injection Molding in China: Tailored Solutions for Your Manufacturing Needs

Read more