The cost-effectiveness of injection molding depends on several factors, including production volume, part complexity, material choice, and tooling costs. Here’s a detailed breakdown to help you understand when injection molding can be considered cheap and when it might be more expensive:

Factors Influencing the Cost of Injection Molding

1. Tooling Costs

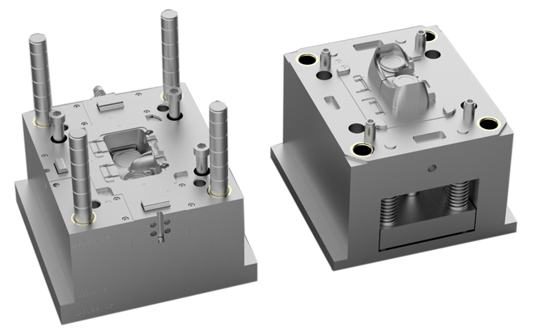

- High Initial Investment: The initial cost of creating the injection mold (tooling) is high, often ranging from a few thousand to hundreds of thousands of dollars. This cost includes design, machining, and testing of the mold.

- Amortization: For high-volume production runs, the tooling cost can be amortized over a large number of parts, making the cost per part very low. For low-volume production, the per-part cost remains high.

2. Production Volume

- High Volume: Injection molding becomes cost-effective for large production volumes due to the low cost per part after the initial mold cost is covered.

- Low Volume: For small production runs, the high tooling cost can make injection molding prohibitively expensive compared to other manufacturing methods.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

3. Material Costs

- Thermoplastics: The cost of the plastic material used in injection molding varies widely. Common materials like polypropylene (PP) and polyethylene (PE) are inexpensive, while engineering plastics like polycarbonate (PC) or PEEK are more costly.

- Additives and Colorants: Additional costs may come from using specific additives or colorants to achieve desired properties or aesthetics.

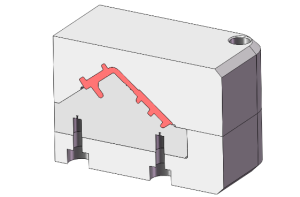

4. Part Complexity

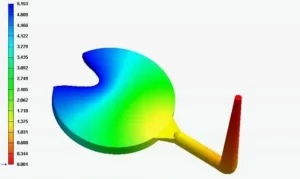

- Simple Parts: Parts with simple geometries and uniform wall thicknesses are cheaper to mold.

- Complex Parts: Complex parts with intricate features, undercuts, or tight tolerances require more sophisticated molds and longer cycle times, increasing the cost.

5. Cycle Time

- Short Cycle Time: Shorter cycle times reduce the overall production cost as more parts can be produced in a given time frame.

- Long Cycle Time: Parts that require longer cooling times or multiple steps in the molding process have higher production costs.

6. Labor and Overhead

- Automation: Highly automated processes reduce labor costs, making injection molding cheaper.

- Manual Processes: Parts requiring manual handling or secondary operations increase labor costs.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Cost Comparison with Other Manufacturing Methods

- 3D Printing:

- Low Volume: More cost-effective for prototyping and low-volume production due to no tooling costs.

- High Volume: Becomes more expensive per part compared to injection molding.

- CNC Machining:

- Low to Medium Volume: Can be cost-effective for low to medium volume production.

- High Complexity: Suitable for complex parts but may be slower and more expensive for high-volume production compared to injection molding.

- Blow Molding, Rotomolding, Thermoforming:

- Alternative Plastic Forming: Other methods might be cheaper for specific types of parts (e.g., hollow or large parts).

When Injection Molding is Cheap

- Large Production Runs: When producing tens of thousands to millions of parts, the high initial tooling cost is offset by the low cost per part.

- Simple Parts: Parts that are simple and quick to mold benefit from lower cycle times and reduced complexity.

- Stable Designs: When the part design is stable and unlikely to change, the investment in a mold pays off over a long production period.

When Injection Molding is Expensive

- Low Volume Production: The high initial tooling cost makes it expensive for short runs.

- Frequent Design Changes: If the design is likely to change frequently, the cost of modifying or creating new molds adds up.

- Complex Parts: Parts requiring intricate molds, multi-cavity setups, or special materials can increase the cost significantly.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Conclusion

Injection molding can be very cost-effective for high-volume production runs of simple, stable part designs. However, it can be expensive for low-volume production, complex parts, or products requiring frequent design changes. By carefully evaluating these factors, manufacturers can determine whether injection molding is the right choice for their specific application and production needs.

Related Conten: https://www.m-dtg.com/service/mold-manufacturing/