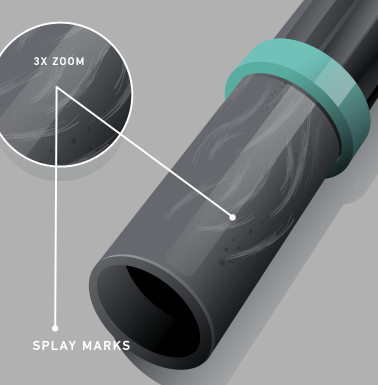

Splay, also known as silver streaking or silvering, is a common defect in injection molding characterized by streaks or lines on the surface of the molded part. This defect is often caused by moisture, gases, or other contaminants in the material or the mold. Here are steps to fix splay in injection molding:

1. Material Preparation

a. Proper Drying

- Dry the Material Thoroughly: Moisture in the plastic resin is a primary cause of splay. Make sure the material is dried according to the manufacturer’s specifications. Use a desiccant dryer or hot air dryer appropriate for the material.

- Check Drying Equipment: Ensure that the drying equipment is functioning correctly and is properly maintained.

b. Material Handling

- Avoid Contamination: Keep the material free from contamination by storing it in a clean, dry environment.

- Use Virgin Material: If possible, use virgin material instead of regrind, which may contain more moisture and contaminants.

2. Machine Settings and Processing Conditions

a. Barrel and Nozzle Temperature

- Optimize Temperatures: Set the barrel and nozzle temperatures to the optimal range for the material. Too high or too low temperatures can contribute to splay by causing degradation or improper melting of the material.

- Check Temperature Uniformity: Ensure that the temperature is consistent across the barrel and nozzle to avoid hot or cold spots that can cause splay.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

b. Injection Speed and Pressure

- Adjust Injection Speed: Lowering the injection speed can help reduce the formation of splay by minimizing the introduction of air and reducing shear stress.

- Optimize Injection Pressure: Set the injection pressure appropriately to ensure a smooth and consistent flow of material into the mold.

c. Back Pressure

- Increase Back Pressure: Higher back pressure during the plasticizing stage can help release trapped gases and air bubbles from the molten plastic.

3. Mold Design and Maintenance

a. Mold Venting

- Improve Venting: Ensure the mold is adequately vented to allow trapped gases to escape. Vents should be placed strategically, especially at the end of the flow path.

- Clean Vents Regularly: Regularly clean the vents to prevent clogging and ensure efficient gas release.

b. Mold Surface

- Polish Mold Surfaces: A smooth mold surface can reduce splay by preventing material buildup and ensuring uniform flow.

- Check for Leaks: Ensure there are no leaks in the mold cooling system that could introduce moisture into the mold cavity.

4. Material and Additives

a. Use of Dehumidifiers

- Dehumidify the Air: In environments with high humidity, use dehumidifiers to reduce the moisture content in the air around the molding machine.

b. Additives

- Consider Additives: Use additives that can help improve the flow and reduce the moisture absorption of the plastic material.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

5. Maintenance and Troubleshooting

a. Regular Maintenance

- Inspect and Maintain Equipment: Regularly inspect and maintain the injection molding machine, including the screw, barrel, and other components, to ensure they are in good condition.

- Clean Equipment: Clean the screw and barrel regularly to remove any buildup that could contribute to splay.

Troubleshooting Steps

If splay persists, follow these troubleshooting steps:

- Check Material Dryness: Confirm that the material is adequately dried and free of moisture.

- Inspect Mold Venting: Ensure that the mold vents are clear and properly positioned.

- Optimize Temperatures: Adjust barrel and nozzle temperatures to the optimal range for the material.

- Adjust Injection Speed and Pressure: Experiment with different injection speeds and pressures to find the optimal settings.

- Increase Back Pressure: Try increasing the back pressure during the plasticizing stage.

- Inspect and Clean Equipment: Regularly inspect and clean the injection molding machine and mold.

By systematically addressing these factors, you can effectively reduce or eliminate splay in injection molding, resulting in higher-quality molded parts.

Related Conten: Expert Large Plastic Molds Manufacturing