Cleaning a plastic injection mold is essential for maintaining product quality, extending mold life, and ensuring consistent production performance. Proper mold cleaning involves removing residues, buildup, and contaminants that can affect the molding process. Here’s a comprehensive guide on how to clean a plastic injection mold:

Tools and Materials Needed

- Soft cloths or lint-free wipes

- Mold cleaner or degreaser

- Compressed air or a vacuum

- Soft brushes (nylon or brass)

- Rust inhibitor or mold protectant

- Personal protective equipment (PPE) such as gloves and safety glasses

Step-by-Step Cleaning Procedure

1. Safety Precautions

- Ensure Safety:

- Follow all safety protocols, including wearing PPE.

- Ensure the machine is properly shut down and locked out to prevent accidental startup.

- Cool Down:

- Allow the mold to cool down to a safe handling temperature before starting the cleaning process.

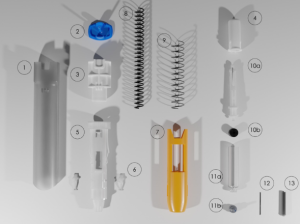

2. Initial Inspection

- Inspect the Mold:

- Conduct a visual inspection of the mold to identify areas with significant buildup, residue, or contaminants.

- Check for any signs of damage or wear that might require repair or maintenance.

3. Surface Cleaning

- Remove Loose Debris:

- Use compressed air or a vacuum to remove loose particles, plastic fragments, and other debris from the mold surfaces.

- Apply Mold Cleaner:

- Apply a mold cleaner or degreaser to the mold surfaces, following the manufacturer’s instructions.

- Use a soft cloth or lint-free wipe to gently clean the mold surfaces, removing any surface residue.

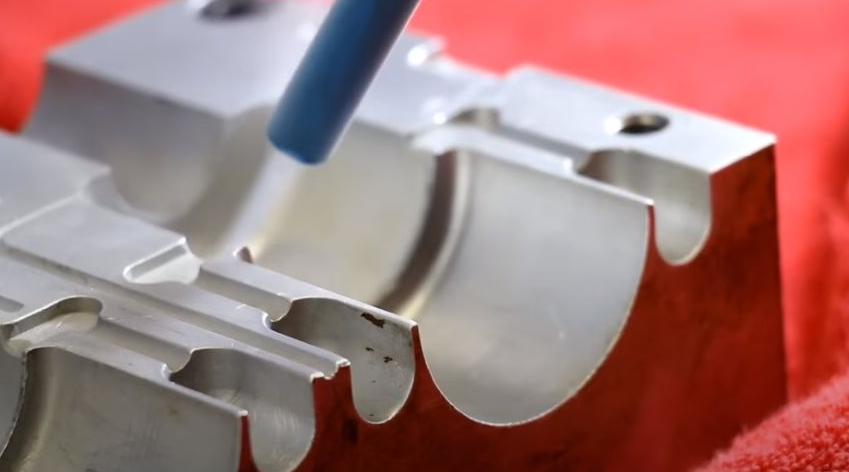

- Brush Cleaning:

- Use soft brushes (nylon or brass) to clean hard-to-reach areas, grooves, and textured surfaces.

- Avoid using abrasive materials that can scratch or damage the mold surfaces.

4. Detailed Cleaning

- Clean Venting Channels and Ejector Pins:

- Pay special attention to venting channels, ejector pins, and other critical areas prone to buildup.

- Use small brushes and mold cleaner to remove residues from these areas.

- Check Cooling Channels:

- Inspect and clean the cooling channels if accessible. Ensure there are no obstructions that could affect cooling efficiency.

- Dry the Mold:

- Use compressed air or a lint-free cloth to thoroughly dry the mold surfaces after cleaning to prevent moisture buildup and corrosion.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

5. Rust Prevention

- Apply Rust Inhibitor:

- Apply a rust inhibitor or mold protectant to the cleaned mold surfaces to prevent corrosion.

- Ensure even coverage, especially in areas prone to moisture accumulation.

6. Final Inspection

- Inspect for Cleanliness:

- Conduct a final inspection to ensure all residues and contaminants have been removed.

- Check for any signs of damage or issues that may require further maintenance.

7. Storage and Maintenance

- Proper Storage:

- If the mold will not be used immediately, store it in a clean, dry environment.

- Use mold storage racks or protective covers to prevent damage and contamination.

- Regular Maintenance:

- Establish a regular maintenance schedule to clean and inspect the mold between production runs.

- Perform preventive maintenance tasks, such as lubrication and component checks, to extend mold life.

Tips for Effective Mold Cleaning

- Frequency: Clean the mold regularly, ideally between production runs, to prevent buildup and ensure consistent part quality.

- Gentle Handling: Handle mold components gently to avoid damage during cleaning.

- Proper Products: Use mold cleaners and rust inhibitors specifically designed for injection molds to avoid damaging mold surfaces.

- Documentation: Keep records of cleaning and maintenance activities to track mold condition and performance over time.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

Proper cleaning and maintenance of plastic injection molds are crucial for ensuring high-quality production, reducing downtime, and extending mold life. By following a systematic cleaning procedure and implementing regular maintenance practices, manufacturers can optimize mold performance and achieve consistent, defect-free molded parts.

Related Conten: Rapid Injection Molding