Plastic injection molding machines are complex pieces of equipment that transform raw plastic material into finished products through a series of carefully controlled steps. Here’s a detailed explanation of how these machines work, covering the major components and the process stages:

Major Components of Injection Molding Machines

- Hopper:

- Function: Stores and feeds the raw plastic material (usually in the form of granules or pellets) into the machine.

- Description: A funnel-shaped container that ensures a steady supply of material to the injection unit.

- Injection Unit:

- Components: Consists of a reciprocating screw, barrel, heaters, and a nozzle.

- Function: Melts and injects the plastic material into the mold.

- Operation: The screw rotates and moves axially within the barrel, melting the plastic via friction and external heaters. The melted plastic is then pushed forward through the nozzle into the mold.

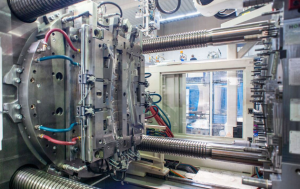

- Clamping Unit:

- Components: Includes the mold, platens (stationary and moving), and the clamping mechanism.

- Function: Holds the mold in place, closes and opens the mold, and applies the necessary clamping force during injection.

- Operation: The clamping unit ensures the mold halves are tightly closed during injection to prevent material leakage and to withstand the injection pressure.

- Mold:

- Components: Typically consists of two halves (the core and the cavity), cooling channels, and ejector pins.

- Function: Shapes the molten plastic into the desired form and cools it to solidify.

- Operation: The mold design is crucial for determining the shape, features, and cooling efficiency of the final product.

The Injection Molding Process

- Clamping:

- Description: The mold halves are closed and securely clamped together using the clamping unit.

- Purpose: Ensures that the mold remains closed under the high pressure of the injection process.

- Injection:

- Description: The screw in the injection unit moves forward, pushing the molten plastic through the nozzle into the mold cavity.

- Purpose: Fills the mold with the right amount of plastic to form the part.

- Cooling:

- Description: The molten plastic inside the mold cools and solidifies into the shape of the cavity.

- Purpose: Solidification ensures that the part retains its shape and can be ejected without deformation.

- Dwelling:

- Description: A period where the injected plastic is held under pressure to ensure complete filling and to pack the material to eliminate voids or sink marks.

- Purpose: Ensures high-quality, defect-free parts.

- Mold Opening:

- Description: The clamping unit opens the mold once the plastic has sufficiently cooled.

- Purpose: Prepares the part for ejection.

- Ejection:

- Description: Ejector pins push the cooled, solidified part out of the mold.

- Purpose: Removes the finished part from the mold, allowing for the next cycle to begin.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Detailed Explanation of Key Stages

Clamping

- Steps: The machine starts by closing the mold halves tightly together. The clamping force must be strong enough to withstand the injection pressure without opening the mold.

- Mechanism: Hydraulic or mechanical systems generate the clamping force. The moving platen carries one half of the mold towards the stationary platen holding the other half.

Injection

- Steps:

- Plasticizing: The raw plastic material is heated and melted inside the barrel.

- Injecting: The screw pushes the molten plastic through the nozzle into the mold cavity.

- Mechanism: The screw’s rotation and axial movement allow for efficient melting and controlled injection of plastic.

Cooling

- Steps: Once the mold cavity is filled, the plastic begins to cool and solidify.

- Mechanism: Cooling channels in the mold circulate coolant (usually water) to remove heat from the plastic. The cooling time depends on the plastic type and part thickness.

Dwelling

- Steps: After filling, additional pressure is applied to pack the plastic tightly and compensate for shrinkage.

- Mechanism: The screw maintains pressure to ensure the mold is fully packed and eliminates voids and defects.

Mold Opening

- Steps: The clamping unit releases the pressure and separates the mold halves.

- Mechanism: Hydraulic or mechanical systems control the opening action.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Ejection

- Steps: Ejector pins push the part out of the mold cavity.

- Mechanism: The ejector system is often hydraulic or pneumatic and carefully timed to push the part without causing damage.

Conclusion

Injection molding machines are sophisticated devices that transform raw plastic material into precise, high-quality parts through a series of well-coordinated steps. By understanding the components and stages involved, manufacturers can optimize the process for efficiency, quality, and cost-effectiveness. Proper maintenance and fine-tuning of each stage are essential to ensure consistent and reliable production outcomes.

Related Conten: Rapid Injection Molding