In injection molding, the cooling of the part is primarily influenced by the cooling time rather than the hold or…

Blogs

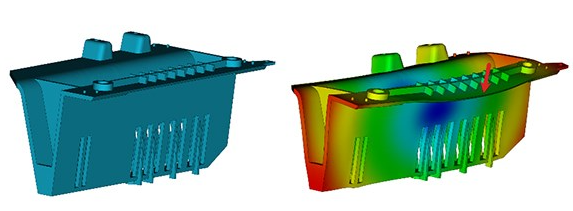

Warping is a common defect in injection molded parts, where the part bends or twists out of shape after cooling….

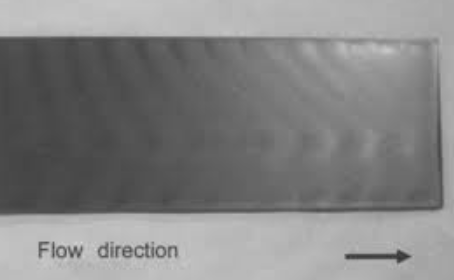

Tiger striping, also known as flow marks or flow lines, is a common surface defect in injection molded parts. These…

Splay, also known as silver streaks or flow lines, is a common defect in injection molded parts that appears as…

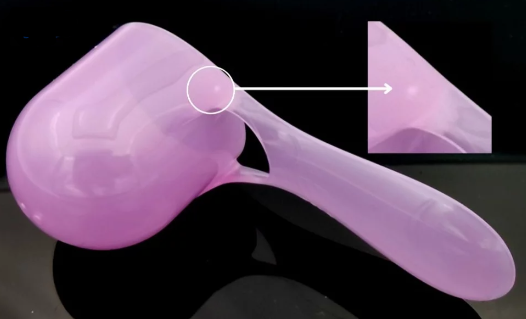

Sinks in injection molding, also known as sink marks, are depressions or dimples on the surface of the molded part….

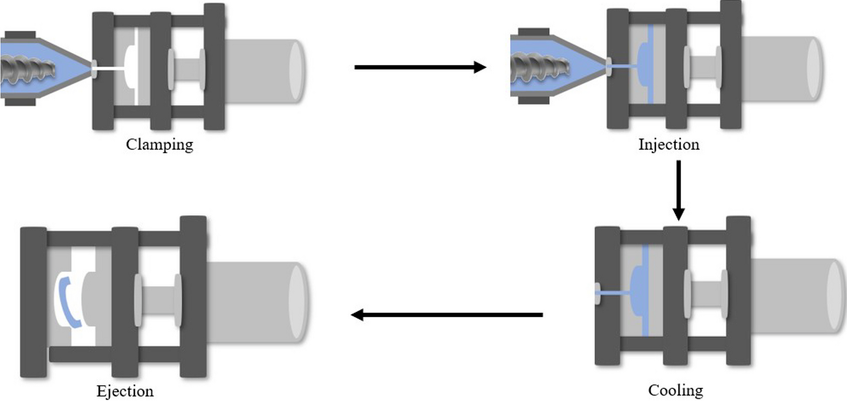

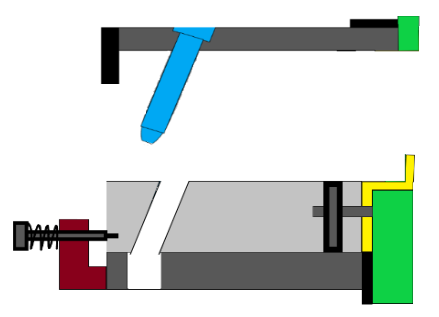

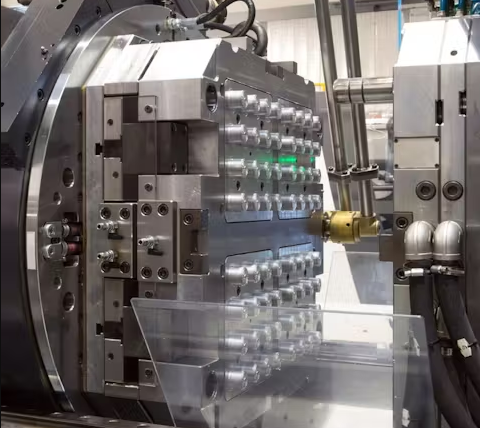

Plastic injection molding is a manufacturing process used to produce parts by injecting molten plastic material into a mold. This…

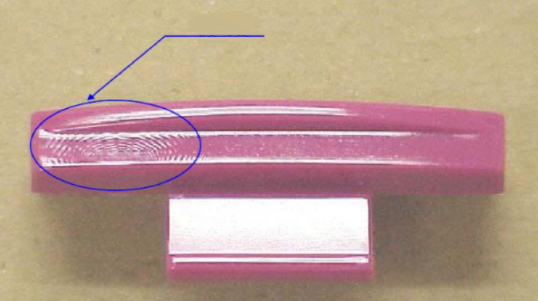

Overview Slider lines on injection molds are marks or lines that appear on the surface of a molded part due…

Sink marks are surface depressions or indentations that appear on injection molded components. These defects typically occur in thicker sections…

Vacuum voids, also known as air pockets or gas pockets, are defects that occur within an injection-molded part. These voids…

Advantages of High Sprue Pressure Disadvantages of High Sprue Pressure Balancing Sprue Pressure In summary, while high sprue pressure can…