Home » Case Products » Custom OEM Plastic for Electric Appliance Parts

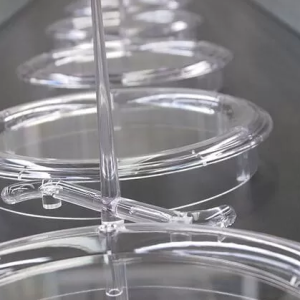

Custom OEM Plastic for Electric Appliance Parts

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Optimize Your Production with Injection Molding Polycarbonate from DTG Injection Molding

Read more -

Elevate Your Products with Expert Appliance Injection Molding Services

Read more -

Hemp Plastic Injection Molding

Read more -

Comprehensive Guide to Injection Molding Defects

Read more -

Custom Plastic Chairs for Your Business

Read more -

Partner with a Leading Injection Mold Manufacturer for Unmatched Quality

Read more

Injection Molding - Prototype Manufacturing

Bring your product idea to life in as soon as 5 days!