Home » Case Products » Aluminum Prototyping: Precision, Strength, and Speed for Your Product Development

Aluminum Prototyping: Precision, Strength, and Speed for Your Product Development

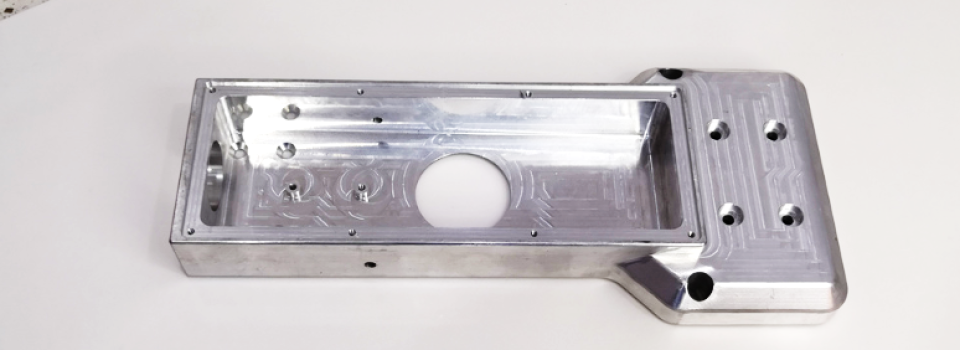

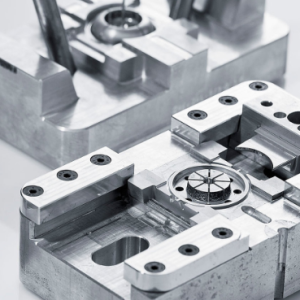

Unlock the benefits of aluminum prototyping for fast, accurate, and durable prototypes that help you bring your products to market quickly and efficiently. Ideal for industries such as aerospace, automotive, electronics, and industrial equipment, aluminum prototyping provides strength, lightweight properties, and excellent machinability, making it the perfect choice for creating functional prototypes.

Why choose our aluminum prototyping services?

- High Precision: Achieve detailed, accurate prototypes with tight tolerances using advanced CNC machining, 3D printing, or casting techniques.

- Durable and Lightweight: Aluminum offers excellent strength-to-weight ratio, making it ideal for both functional testing and design validation.

- Fast Turnaround: Accelerate your product development with rapid prototyping, allowing for quicker iterations and faster time-to-market.

- Cost-Effective Solutions: Save time and reduce costs by refining your designs early in the development process, minimizing expensive design revisions during production.

- Custom Designs: Tailored aluminum prototyping services to meet your unique design and material needs, whether for simple components or complex assemblies.

Elevate your product development with our aluminum prototyping solutions. Contact us today to discover how we can help you create high-quality, functional prototypes that streamline your path to production.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Factory Custom ABS Made Molded Plastic Casing Products

Read more -

Hemp Plastic Injection Molding

Read more -

Small Batch Injection Molding

Read more -

Injection Molding for Medical Devices

Read more -

Lexan Injection Molding

Read more -

Custom Injection Molds: Precision Solutions for Your Manufacturing Needs

Read more