Home » Case Products » Innovate Your Products with Expert Two Shot Injection Molding

Innovate Your Products with Expert Two Shot Injection Molding

At DTG Injection Molding, we specialize in two shot injection molding, a cutting-edge process that allows for the creation of complex, multi-material parts in a single molding cycle. Our expertise in this advanced technique ensures superior quality, efficiency, and innovation for your products.

Why Choose DTG Injection Molding for Two Shot Injection Molding?

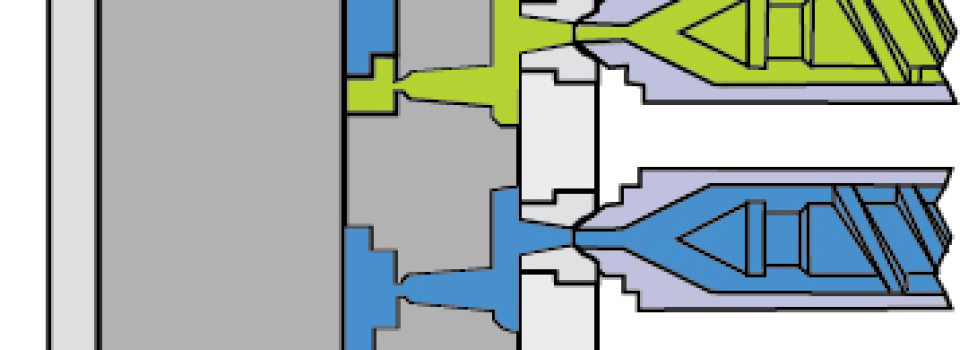

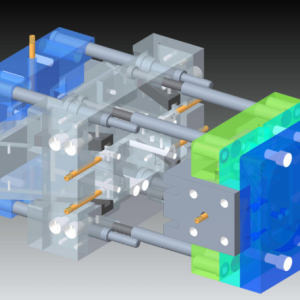

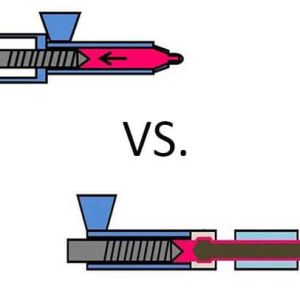

1. Advanced Multi-Material Capability: Two shot injection molding combines two different materials into one cohesive part. This process allows for the integration of various textures, colors, and functionalities, enhancing the design and performance of your products.

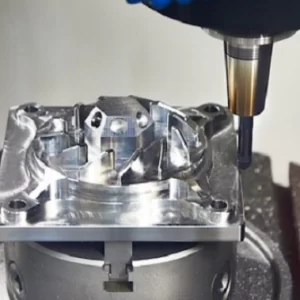

2. Superior Part Quality: Our two shot injection molding process ensures strong bonds between materials, resulting in durable and high-quality parts. The precise control of the molding process guarantees that each component meets stringent quality standards.

3. Design Flexibility: Two shot injection molding offers unparalleled design flexibility. Whether you need soft-touch grips over rigid structures, intricate color patterns, or functional elements like seals and gaskets, our technology can bring your innovative designs to life.

4. Cost and Time Efficiency: By molding two materials in a single cycle, two shot injection molding reduces the need for secondary operations, saving both time and money. This efficient process minimizes production steps and accelerates your time-to-market.

5. Enhanced Product Functionality: Combining different materials in a single part can significantly enhance product functionality. From improved ergonomics to added durability and aesthetic appeal, two shot injection molding provides multifunctional benefits that set your products apart.

6. Consistent and Reliable Results: Our state-of-the-art machinery and expertise ensure consistent and reliable outcomes for every project. We maintain strict process controls to deliver uniform quality across all production runs.

7. Comprehensive Support: Our experienced team offers full support throughout your project, from initial concept and design to final production. We work closely with you to understand your needs and provide solutions that meet your exact specifications.

Experience the Innovation of Two Shot Injection Molding with DTG Injection Molding

Elevate your product designs and functionality with our expert two shot injection molding services. Contact DTG Injection Molding today to discuss your project and discover how we can help you achieve innovative and high-quality results.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Prototype CNC Machining: Precision Prototypes for Rapid Development

Read more -

Product Prototyping Services: Transform Your Ideas into Market-Ready Prototypes

Read more -

Elevate Your Products with Expert Mold Injection Design

Read more -

Polypropylene Injection Molding

Read more -

Extrusion vs Injection Molding: Choosing the Right Manufacturing Process for Your Needs

Read more -

Custom Injection Molding Companies: Tailored Solutions for Your Unique Needs

Read more