Home » Case Products » Optimize Your Production with High-Quality Injection Molding Tools

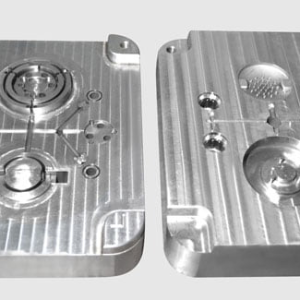

Optimize Your Production with High-Quality Injection Molding Tools

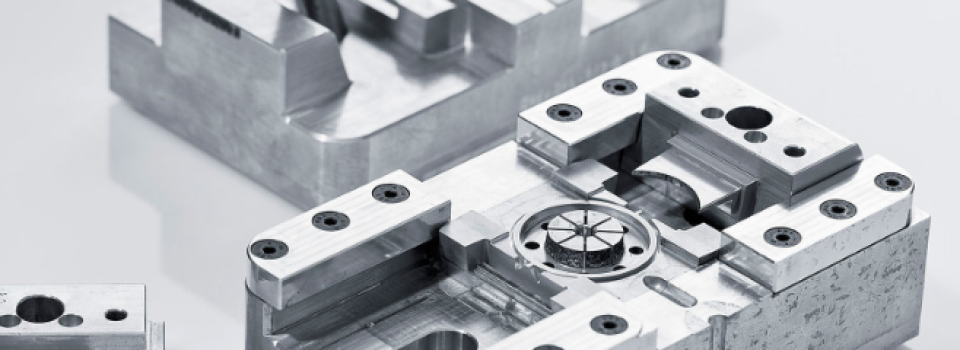

At DTG Injection Molding, we specialize in providing top-tier injection molding tools that drive efficiency, precision, and quality in your manufacturing process. Our commitment to excellence ensures you receive the best tools to meet your specific needs and enhance your production capabilities.

Why Choose Our Injection Molding Tools?

1. Superior Quality: Our injection molding tools are crafted from high-grade materials, ensuring durability and longevity. We adhere to the highest quality standards, guaranteeing tools that deliver consistent and reliable performance.

2. Precision Engineering: We understand the importance of accuracy in injection molding. Our tools are engineered with meticulous precision to ensure exact dimensions and tolerances, resulting in flawless parts and components.

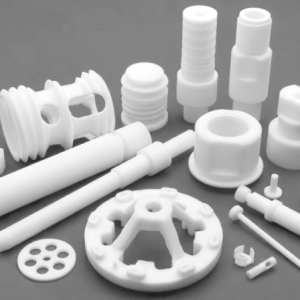

3. Custom Solutions: Every project is unique. We offer custom injection molding tools tailored to your specific requirements. Whether you need intricate designs, complex geometries, or high-volume production, our tools are designed to meet your exact specifications.

4. Advanced Technology: Utilizing state-of-the-art technology, our manufacturing process ensures high efficiency and superior quality. Our advanced machinery and techniques enable us to produce injection molding tools that enhance your production efficiency.

5. Competitive Pricing: Quality doesn’t have to come at a high cost. Our efficient production processes and competitive pricing structures ensure you receive high-quality tools at affordable prices, optimizing your investment.

6. Expert Support: Our team of experienced professionals is dedicated to providing exceptional customer support. From initial consultation to final delivery, we offer guidance and assistance at every step to ensure your project’s success.

7. Quick Turnaround: Time is critical in the manufacturing industry. Our streamlined processes and efficient production schedules guarantee quick turnaround times, helping you stay on track and meet your deadlines.

Enhance Your Manufacturing with DTG Injection Molding Tools

Invest in high-quality injection molding tools from DTG Injection Molding and experience the difference in performance and precision. Contact us today to discuss your tooling needs and discover how we can support your production goals.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

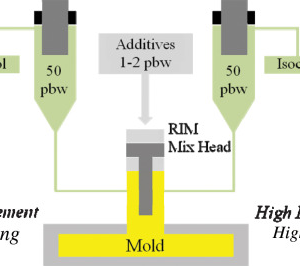

Revolutionize Your Production with RIM Injection Molding

Read more -

Small Run Injection Molding: Cost-Effective Solutions for Low-Volume Production

Read more -

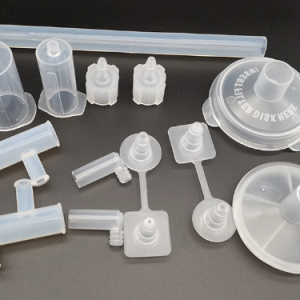

Injection Molded Plastic Packaging

Read more -

Top-Notch Aluminum Injection Molding Solutions

Read more -

Injection Molded Plastic Containers

Read more -

Get Your Injection Molding Instant Quote Today with DTG Injection Molding

Read more