Home » Case Products » Innovative PEEK Injection Molding for Precision Parts

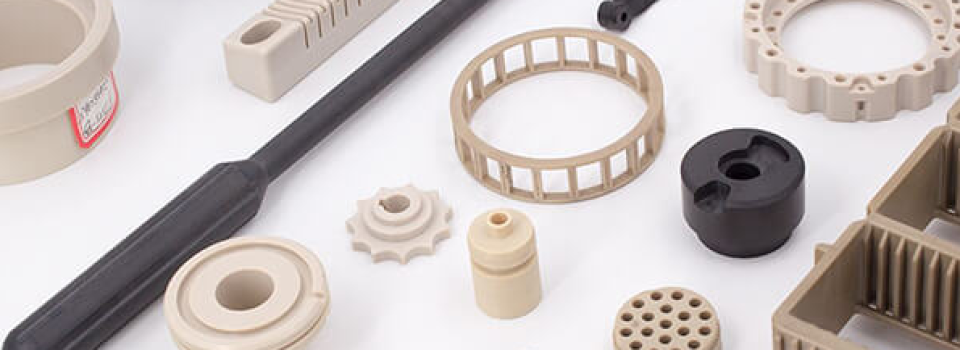

Innovative PEEK Injection Molding for Precision Parts

High-Performance Parts

Our PEEK injection molding technology ensures that you receive parts with exceptional performance and durability. We cater to various industries, delivering solutions that meet stringent requirements.

Efficient and Reliable Production

Our advanced PEEK injection molding process enables efficient production, ensuring that your parts are delivered on time without compromising quality. This makes us a trusted partner for high-volume manufacturing needs.

Custom PEEK Injection Molding Solutions

- Tailored to Your Needs

- Description: We offer custom PEEK injection molding solutions designed to meet your specific project requirements.

- Benefits: Personalized service and parts that match your exact specifications.

- Prototyping Services

- Description: Rapid prototyping to test and refine your designs before full-scale production.

- Benefits: Reduced development time and cost, ensuring optimal part performance.

- Material Expertise

- Description: Extensive knowledge of PEEK materials and their properties.

- Benefits: Guidance in selecting the best material for your application.

Why Our PEEK Injection Molding Solutions Stand Out

- Precision and Quality

- Overview: Advanced equipment and techniques ensure precise, high-quality parts.

- Benefits: Reliable components that meet stringent specifications.

- Cost-Effective Production

- Overview: Efficient processes and high-volume capabilities reduce production costs.

- Benefits: Affordable solutions without compromising on quality.

Partner with DTG for Superior PEEK Injection Molding Solutions

At DTG Injection Molding, we are committed to delivering high-quality PEEK injection molding solutions that meet your specific needs. Our expertise, advanced technology, and dedication to quality ensure that you receive the best possible results.

Contact Us Today

Ready to start your PEEK injection molding project? Contact DTG Injection Molding for expert advice, competitive quotes, and top-notch solutions. Let us help you achieve superior results with our advanced PEEK capabilities.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Get Your Injection Molding Instant Quote Today with DTG Injection Molding

Read more -

Structural Foam Injection Molding: Strength and Efficiency Combined

Read more -

Factory Insert for Custom Plastic Parts

Read more -

Polymer Injection Molding

Read more -

Injection Molded Plastic Letters

Read more -

Plastic Shell Electronic Plastic Accessories Factory Custom ABS Plastic Mold Processing

Read more