Home » Case Products » Ejector Pins in Injection Molding: Essential Components for Precision

Ejector Pins in Injection Molding: Essential Components for Precision

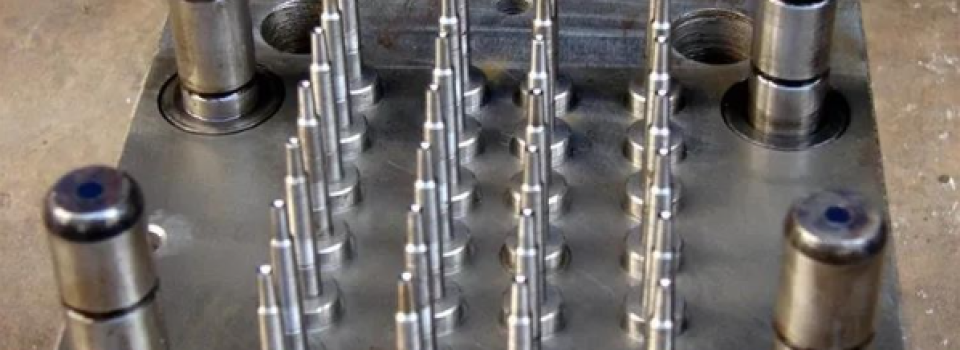

At DTG Injection Molding, we understand the crucial role of ejector pins in the injection molding process. These components are essential for the smooth ejection of parts from molds, ensuring precision and quality in every production run.

What are Ejector Pins?

Ejector pins are slender rods used in injection molding to eject molded parts from the mold once the plastic has solidified. Positioned in various locations within the mold, these pins push the part out without causing damage, ensuring a clean release.

Key Benefits of Ejector Pins

- Precision and Accuracy

- Overview: Ejector pins ensure that parts are ejected with minimal distortion.

- Benefits: High-quality, consistent parts with precise dimensions.

- Efficiency in Production

- Overview: Facilitates quick and easy removal of parts from molds.

- Benefits: Faster cycle times and increased production efficiency.

- Versatility

- Overview: Suitable for various types of molds and part designs.

- Benefits: Adaptable to different manufacturing needs and requirements.

- Durability

- Overview: Made from high-strength materials to withstand repeated use.

- Benefits: Long-lasting performance and reduced maintenance costs.

Types of Ejector Pins

- Standard Ejector Pins

- Description: Basic pins used in most injection molding applications.

- Applications: Suitable for general-purpose molds and parts.

- Shoulder Ejector Pins

- Description: Feature a shoulder that acts as a stop for precise positioning.

- Applications: Used for parts requiring exact ejection positioning.

- Blade Ejector Pins

- Description: Thin, flat pins designed for ejecting parts with thin walls.

- Applications: Ideal for complex and delicate parts.

- Stepped Ejector Pins

- Description: Feature a step for increased strength and stability.

- Applications: Suitable for heavy-duty applications and larger parts.

The Role of Ejector Pins in Injection Molding

Ensuring Clean Ejection

Ejector pins are strategically placed to apply even pressure across the part, ensuring a clean release without warping or damaging the part. This is crucial for maintaining the integrity and quality of the molded product.

Enhancing Production Efficiency

By enabling quick and reliable ejection of parts, ejector pins help reduce cycle times and improve overall production efficiency. This leads to higher throughput and lower manufacturing costs.

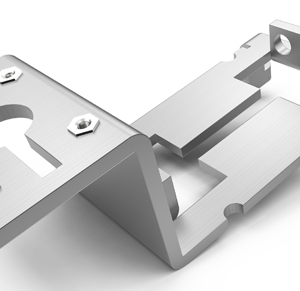

Customization and Adaptability

Ejector pins can be customized to fit specific mold designs and part requirements. This flexibility ensures that they can be used in a wide range of applications, from simple to highly complex parts.

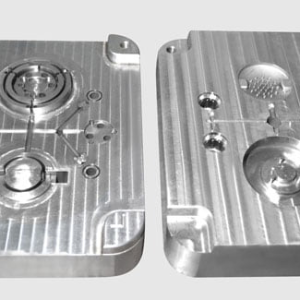

DTG Injection Molding: Expert Solutions for Ejector Pins

At DTG Injection Molding, we provide high-quality ejector pins that meet your specific needs. Our expert team ensures that each pin is precisely manufactured and positioned for optimal performance.

- High-Quality Materials: Our ejector pins are made from durable materials that ensure long-lasting performance.

- Precision Engineering: Each pin is crafted with precision to ensure accurate and consistent ejection.

- Custom Solutions: We offer customized ejector pins tailored to your mold design and part requirements.

Ejector Pins and Part Quality

- Reducing Defects

- Description: Properly designed and positioned ejector pins reduce the risk of defects such as warping or surface blemishes.

- Outcome: Higher quality parts with consistent performance.

- Maintaining Dimensional Accuracy

- Description: Ejector pins ensure parts maintain their intended dimensions during ejection.

- Outcome: Precision parts that meet strict specifications.

- Improving Surface Finish

- Description: Clean ejection minimizes surface imperfections, resulting in a better finish.

- Outcome: Aesthetic and functional parts with superior surface quality.

How to Choose the Right Ejector Pins

- Assess Part Design

- Consideration: Evaluate the complexity and size of the part to determine the type and placement of ejector pins.

- Action: Choose pins that provide even pressure and clean ejection.

- Material Compatibility

- Consideration: Ensure that the material of the ejector pins is compatible with the mold and part material.

- Action: Select high-strength, durable materials for long-lasting performance.

- Customization Needs

- Consideration: Determine if custom ejector pins are needed for specific mold designs or part features.

- Action: Work with an expert provider to design and produce custom pins.

Get Started with DTG Injection Molding

- Contact Us: Reach out via our online form, email, or phone to discuss your ejector pin needs.

- Share Your Project Details: Provide information about your mold design and part requirements.

- Receive a Quote: We’ll offer a detailed, competitive quote based on your specifications.

- Begin Production: Once approved, we’ll start the manufacturing process, ensuring timely delivery of your high-quality ejector pins.

Connect with DTG Today

Looking for reliable ejector pins for your injection molding needs? Contact DTG Injection Molding for expert advice, competitive quotes, and top-notch products. Let us help you achieve superior results with our high-quality ejector pins and injection molding solutions.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

PPE Injection Molding: High-Quality, Precision Molding for Personal Protective Equipment

Read more -

Quick Turn Sheet Metal: Fast, High-Precision Metal Fabrication for Rapid Prototyping

Read more -

Top-Notch Aluminum Injection Molding Solutions

Read more -

Plastic Sport Toy Plastic Minifigure

Read more -

Custom Automotive Original Plastic Fittings Service

Read more -

Silicone Injection Molding Solutions

Read more