Home » Case Products » Understanding Short Shot Injection Molding: Causes and Solutions

Understanding Short Shot Injection Molding: Causes and Solutions

At DTG Injection Molding, we understand the intricacies of short shot injection molding and how it can impact your production process. Our expertise and advanced techniques help mitigate and resolve short shot issues, ensuring high-quality, consistent results for your injection molding projects.

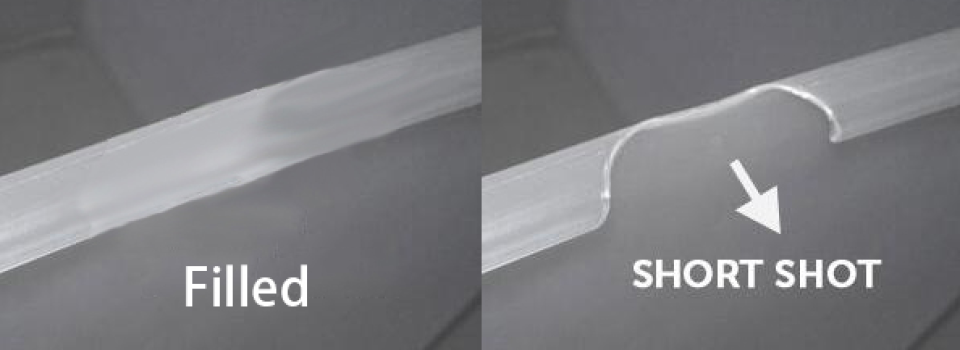

What is Short Shot Injection Molding?

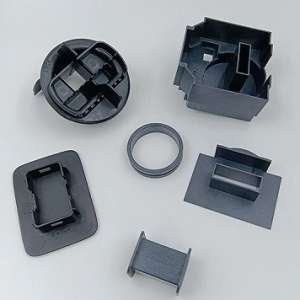

Short shot injection molding occurs when the injected material fails to completely fill the mold cavity, resulting in incomplete or defective parts. This issue can lead to production delays, increased costs, and compromised product quality.

Key Causes of Short Shot Injection Molding

- Inadequate Injection Pressure

- Overview: Low injection pressure may not force the material fully into the mold, causing incomplete filling.

- Solution: Adjusting the injection pressure settings can improve material flow and mold filling.

- Improper Material Temperature

- Overview: Material that is too cold or too hot can affect its flow properties and filling capabilities.

- Solution: Ensure that the material is heated to the optimal temperature for proper flow and filling.

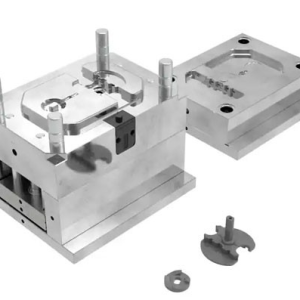

- Mold Design Issues

- Overview: Poor mold design, including insufficient venting or complex geometries, can impede material flow.

- Solution: Review and optimize mold design to enhance flow and reduce the risk of short shots.

- Blockages in the Feed System

- Overview: Blockages or restrictions in the feed system can prevent proper material flow into the mold.

- Solution: Regular maintenance and inspection of the feed system can prevent and address blockages.

- Inconsistent Material Flow

- Overview: Variations in material flow can lead to uneven filling and short shots.

- Solution: Implementing flow analysis and adjusting the process parameters can help ensure consistent material flow.

How to Prevent and Address Short Shot Issues

- Optimize Injection Parameters

- Overview: Fine-tuning parameters such as injection pressure, speed, and temperature can improve mold filling and reduce short shots.

- Benefits: Enhanced part quality, reduced defects, and improved production efficiency.

- Improve Mold Design

- Overview: Incorporating features such as better venting and optimizing cavity design can enhance mold performance and reduce short shots.

- Benefits: Better material flow, more complete mold filling, and fewer defects.

- Regular Equipment Maintenance

- Overview: Conducting routine maintenance on injection molding machines and components ensures optimal performance and reduces the risk of issues.

- Benefits: Reliable operation, fewer production interruptions, and extended equipment lifespan.

- Material Quality and Handling

- Overview: Using high-quality materials and proper handling techniques can improve flow properties and reduce the likelihood of short shots.

- Benefits: Consistent material performance and improved part quality.

- Utilize Advanced Technologies

- Overview: Employing technologies such as mold flow simulation and real-time monitoring can help identify and address potential short shot issues before they occur.

- Benefits: Proactive problem-solving, enhanced mold design, and optimized production processes.

Benefits of Addressing Short Shot Injection Molding

- Improved Part Quality

- Overview: Eliminating short shots ensures that parts meet design specifications and functional requirements.

- Benefits: Higher-quality products and reduced need for rework or scrapping.

- Increased Production Efficiency

- Overview: Resolving short shot issues reduces production delays and downtime, leading to more efficient operations.

- Benefits: Faster turnaround times and lower production costs.

- Cost Savings

- Overview: Addressing short shots reduces waste and rework, leading to cost savings in materials and labor.

- Benefits: More cost-effective manufacturing and better resource utilization.

- Enhanced Customer Satisfaction

- Overview: Consistent, high-quality parts meet customer expectations and improve overall satisfaction.

- Benefits: Stronger customer relationships and improved market reputation.

Get Expert Help with Short Shot Injection Molding

- Contact Us: Reach out via our online form, email, or phone to discuss your short shot injection molding concerns.

- Share Your Project Details: Provide information about your mold design, material specifications, and production requirements.

- Receive a Customized Solution: Our experts will analyze your situation and provide tailored recommendations to address short shot issues.

- Implement Solutions: We’ll work with you to optimize your process and ensure high-quality results.

Connect with DTG Today

Looking for solutions to short shot injection molding issues? Contact DTG Injection Molding for expert advice, customized solutions, and high-quality injection molding services. Let us help you achieve flawless results and enhance your production process.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Custom Plastic Bracelets – Plastic Molding

Read more -

Custom Injection Molding Companies: Tailored Solutions for Your Unique Needs

Read more -

Premium Custom Injection Mold Services

Read more -

Polyurethane Foam Injection Molding

Read more -

Product Prototype Company: Precision and Innovation for Your Design Needs

Read more -

Thermoset Injection Molding

Read more