Home » Case Products » Essential Injection Molding Supplies for Optimal Production

Essential Injection Molding Supplies for Optimal Production

At DTG Injection Molding, we offer a comprehensive range of injection molding supplies to support every aspect of your production process. From high-quality molds to advanced accessories, our supplies are designed to enhance efficiency, improve part quality, and streamline your manufacturing operations.

Explore Our Comprehensive Injection Molding Supplies

We provide a wide array of supplies to meet the diverse needs of injection molding operations. Our products are engineered for precision, durability, and performance.

Key Injection Molding Supplies We Offer

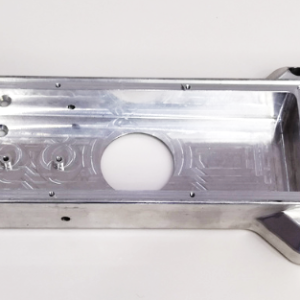

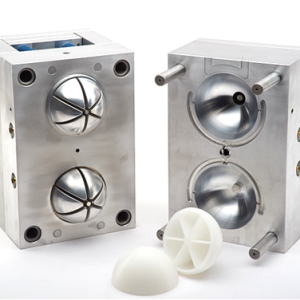

- Mold Components

- Overview: Includes mold bases, cavities, cores, and inserts essential for constructing and maintaining molds.

- Benefits: High-quality components ensure precision and longevity in your molds, reducing maintenance and downtime.

- Injection Molding Machines

- Overview: Advanced machines that perform the injection process with accuracy and efficiency.

- Benefits: Enhanced control over molding parameters, improved cycle times, and consistent part quality.

- Heating and Cooling Systems

- Overview: Systems designed to regulate the temperature of the mold for optimal melting and cooling of materials.

- Benefits: Ensures uniform temperature distribution, reduces cycle times, and improves part quality.

- Mold Release Agents

- Overview: Products used to facilitate the easy removal of parts from the mold, preventing sticking and damage.

- Benefits: Minimizes defects and extends the lifespan of your molds.

- Injection Molding Screws and Barrels

- Overview: Critical components that handle material melting and injection, available in various designs for different applications.

- Benefits: Improved material flow, mixing, and overall molding efficiency.

- Additives and Colorants

- Overview: Additives and colorants used to modify material properties and achieve desired colors.

- Benefits: Tailor material characteristics and enhance the appearance of molded parts.

- Inspection and Testing Equipment

- Overview: Tools and equipment for quality control, including measurement systems and testing rigs.

- Benefits: Ensures parts meet specifications and maintains high quality throughout production.

Why Choose DTG Injection Molding Supplies?

- High-Quality Standards

- Overview: Our supplies are manufactured to the highest industry standards, ensuring reliability and performance.

- Benefits: Consistent results, reduced downtime, and longer equipment life.

- Comprehensive Selection

- Overview: We offer a wide range of supplies to cover all aspects of the injection molding process.

- Benefits: One-stop shop for all your molding needs, simplifying procurement and inventory management.

- Expert Support

- Overview: Our knowledgeable team provides expert advice and support to help you select the right supplies for your application.

- Benefits: Access to industry insights and technical assistance to optimize your molding operations.

- Competitive Pricing

- Overview: We offer high-quality supplies at competitive prices, providing excellent value for your investment.

- Benefits: Cost-effective solutions without compromising on quality or performance.

Applications of Our Injection Molding Supplies

- Automotive Industry: Supplies for manufacturing durable automotive parts and components with precise specifications.

- Medical Devices: High-quality components and equipment for producing medical devices with stringent quality requirements.

- Consumer Goods: Supplies for molding everyday products, including household items and packaging.

- Electronics: Advanced supplies for producing electronic components with complex geometries and high performance.

- Industrial Equipment: Robust supplies for molding industrial parts and machinery, ensuring reliability and functionality.

How to Order Your Injection Molding Supplies

- Contact Us: Reach out via our online form, email, or phone to discuss your supply needs.

- Specify Your Requirements: Provide details about the supplies you need, including quantities, specifications, and any special requirements.

- Receive a Quote: We’ll prepare a detailed quote based on your requirements and provide information on pricing and availability.

- Place Your Order: Once approved, we will process and deliver your supplies promptly, ensuring you have what you need to keep your production running smoothly.

Connect with Us Today

Ready to enhance your production with top-quality injection molding supplies? Contact DTG Injection Molding today to get expert advice and a competitive quote. Let us help you achieve optimal results with our comprehensive range of molding supplies.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Air Flow Sensor Custom Precision Plastic Injection Molding

Read more -

Aluminum Prototyping: Precision, Strength, and Speed for Your Product Development

Read more -

EVA Injection Molding Solutions

Read more -

Injection Mold Maker: Precision Craftsmanship for Superior Manufacturing

Read more -

Prototype Plastic Injection Molding: Accelerate Your Product Development

Read more -

Low Volume Plastic Injection Molding Solutions

Read more