Home » Case Products » Desktop Injection Molding: Precision and Efficiency for Small-Scale Production

Desktop Injection Molding: Precision and Efficiency for Small-Scale Production

DTG Injection Molding offers cutting-edge desktop injection molding solutions designed to deliver high precision and efficiency for small-scale production needs. Ideal for prototyping and low-volume manufacturing, our desktop molding services provide cost-effective and reliable solutions for various applications.

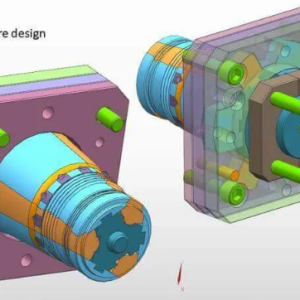

What is Desktop Injection Molding?

Desktop injection molding refers to a compact, efficient molding process used for producing small quantities of high-quality parts. Utilizing advanced technology, desktop machines offer precision and flexibility, making them perfect for prototyping, custom parts, and small production runs.

Advantages of Desktop Injection Molding

- Compact and Space-Efficient

- Overview: Desktop injection molding machines are designed to fit in smaller workspaces, providing a practical solution for limited environments.

- Benefits: Ideal for labs, design studios, and small workshops with space constraints.

- Cost-Effective Prototyping

- Overview: The desktop molding process offers an affordable option for producing prototypes and small batches, reducing initial costs.

- Benefits: Enables rapid design iterations and testing without large-scale investment.

- High Precision and Quality

- Overview: Despite their size, desktop injection molding machines deliver precise and consistent results, ensuring high-quality components.

- Benefits: Reliable performance and accuracy for detailed and complex parts.

- Versatile Applications

- Overview: Suitable for a wide range of materials and part designs, including custom shapes and intricate details.

- Benefits: Flexibility to meet diverse production and design needs.

Our Desktop Injection Molding Services

- Custom Prototyping

- Description: We provide custom prototyping services using desktop injection molding to create functional and high-quality prototypes.

- Applications: Product development, design validation, and concept testing.

- Small-Batch Production

- Description: Our desktop molding capabilities support low-volume production runs, perfect for limited-edition products and small orders.

- Applications: Limited-run products, specialized components, and niche markets.

- Rapid Design Iteration

- Description: Quickly iterate and refine your designs with our rapid prototyping services, enabling fast adjustments and improvements.

- Applications: Design optimization, feature testing, and product enhancements.

- Material Flexibility

- Description: We work with various materials, including plastics and composites, to produce parts that meet your specific requirements.

- Applications: Functional prototypes, custom parts, and material testing.

Industries We Serve

- Consumer Goods: Prototypes and small-scale production for everyday items, including gadgets and accessories.

- Electronics: Custom components and enclosures for electronic devices and equipment.

- Medical Devices: Precision parts for medical devices, focusing on functionality and reliability.

- Automotive: Specialized parts and prototypes for automotive applications and accessories.

- Educational Institutions: Prototyping and small-batch production for research, teaching, and innovation projects.

Why Choose DTG Injection Molding?

- Advanced Technology: Our desktop molding machines utilize the latest technology to ensure precision and efficiency in every project.

- Experienced Team: Our skilled team has extensive experience in desktop injection molding, providing expert support and advice.

- Flexible Solutions: We offer customized solutions to meet your specific prototyping and small-scale production needs.

- Competitive Pricing: Cost-effective services that deliver high-quality results without breaking the bank.

Get Started with Desktop Injection Molding

- Contact Us: Reach out via our online form, email, or phone to discuss your desktop molding needs.

- Submit Your Design: Provide your design files and production requirements for review.

- Receive a Quote: We will offer a detailed, competitive quote based on your specifications.

- Initiate Production: Once approved, we will start the molding process, ensuring timely and accurate results.

Connect with Us Today

Looking for reliable desktop injection molding services? Contact DTG Injection Molding today to discuss your project and receive a prompt, accurate quote. Let us help you achieve exceptional results with our expert desktop molding solutions.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Your Go-To Partner Among Plastic Injection Molding Companies

Read more -

Achieve Excellence with Expert Injection Molding Design

Read more -

High-Quality Rubber Injection Molding Services

Read more -

Injection Molding Toys Solutions

Read more -

Transform Your Concepts with Expert Injection Mold Prototypes

Read more -

Micro Plastic Injection Molding

Read more