Home » Case Products » Comprehensive Guide to Injection Molding Materials

Comprehensive Guide to Injection Molding Materials

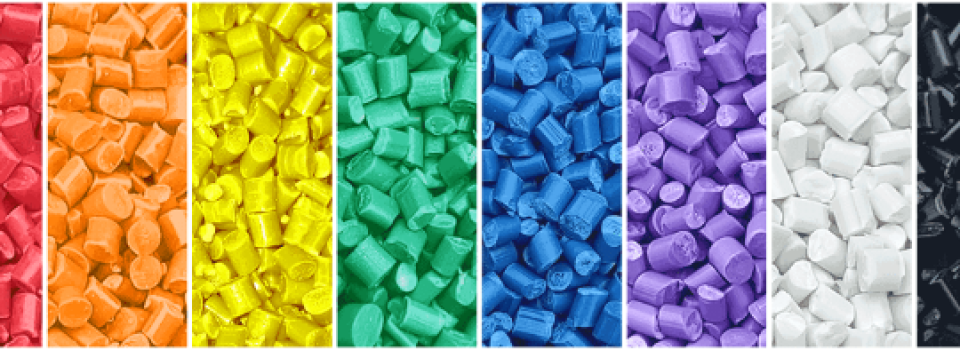

Choosing the right injection molding materials is crucial for the success of any project. At DTG Injection Molding, we offer a wide range of high-quality materials to meet diverse application needs. Our expertise in material selection ensures that your parts are durable, reliable, and perfectly suited to their intended use.

Common Injection Molding Materials

- ABS (Acrylonitrile Butadiene Styrene)

- Description: A strong, durable plastic with good impact resistance and toughness.

- Applications: Automotive parts, consumer electronics, and household appliances.

- Polypropylene (PP)

- Description: A versatile, lightweight material with excellent chemical resistance and flexibility.

- Applications: Packaging, medical devices, and automotive components.

- Polycarbonate (PC)

- Description: A tough, transparent material with high impact resistance and optical clarity.

- Applications: Safety equipment, optical lenses, and electronic components.

- Nylon (Polyamide)

- Description: A strong, wear-resistant material with good chemical and temperature resistance.

- Applications: Gears, bearings, and industrial components.

- Polyethylene (PE)

- Description: A durable, flexible material with excellent chemical resistance and low moisture absorption.

- Applications: Containers, pipes, and consumer goods.

- PBT (Polybutylene Terephthalate)

- Description: A thermoplastic polyester with excellent electrical properties and dimensional stability.

- Applications: Electrical components, automotive parts, and industrial equipment.

Factors to Consider When Choosing Injection Molding Materials

- Mechanical Properties: Consider the material’s strength, flexibility, and impact resistance based on the part’s requirements.

- Chemical Resistance: Ensure the material can withstand exposure to chemicals and other environmental factors.

- Thermal Properties: Assess the material’s heat resistance and suitability for high-temperature applications.

- Cost-Effectiveness: Balance material performance with cost to achieve an optimal solution for your project.

- Aesthetic Requirements: Select materials that meet the desired appearance and finish specifications for your parts.

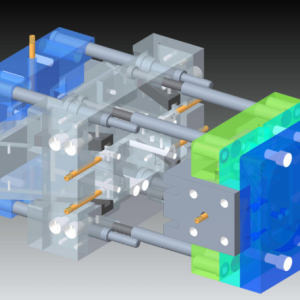

Our Material Selection Process

- Consultation: We work closely with you to understand your project requirements, application, and performance needs.

- Material Analysis: Our experts analyze various materials to identify the best options based on your specifications.

- Testing and Validation: We conduct thorough testing to validate material performance and ensure it meets all requirements.

- Customization: If needed, we can blend or modify materials to achieve specific properties tailored to your project.

Why Choose DTG Injection Molding for Material Selection?

- Extensive Experience: Our team has years of experience in selecting and working with a wide range of injection molding materials.

- High-Quality Standards: We use only high-quality materials that meet industry standards and ensure the best performance for your parts.

- Innovative Solutions: We provide innovative material solutions to meet the unique challenges of your project.

- Customer-Centric Approach: We prioritize your needs and work closely with you to ensure complete satisfaction with the material selection process.

How to Get Started with Your Injection Molding Project

- Contact Us: Reach out to us via our online form, email, or phone to discuss your project requirements.

- Provide Specifications: Share your design files, material preferences, and expected quantity with our team.

- Receive a Quote: We will review your project details and provide a detailed, competitive quote within 24 hours.

- Project Execution: Upon approval, our team will begin the design and production process, ensuring timely and high-quality delivery.

Contact Us Today

Ready to select the best injection molding materials for your project? Contact DTG Injection Molding today to discuss your requirements and receive a fast, accurate quote. Let us help you achieve superior results with our expert material selection and injection molding services.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Nylon Plastic Injection Molding Services

Read more -

Metal Injection Molding in China: Precision and Efficiency for Your Metal Parts

Read more -

Plastic Prototype: Fast, Flexible, and Cost-Effective Prototyping Solutions

Read more -

Prototype Machining Services: Precision and Speed for Your Product Development

Read more -

Thermoforming vs Injection Molding: Choosing the Right Process

Read more -

Elevate Your Products with Expert Mold Injection Design

Read more