Home » Case Products » Understanding the Cost of Injection Molding

Understanding the Cost of Injection Molding

When planning an injection molding project, understanding the cost factors involved is crucial for making informed decisions. At DTG Injection Molding, we provide transparent pricing and detailed cost breakdowns to help you budget effectively and maximize your investment.

What Influences the Cost of Injection Molding?

- Design Complexity: The complexity of the mold design can significantly impact costs. Intricate designs require more time and precision, increasing both design and production expenses.

- Material Selection: Different materials have varying costs. Engineering-grade resins, specialty polymers, and additives can affect the overall price.

- Production Volume: Higher production volumes typically reduce the cost per unit due to economies of scale. Low-volume production may have higher per-unit costs.

- Tooling Costs: The initial cost of creating the mold (tooling) is a significant factor. High-precision, durable molds for large production runs may be more expensive than those for smaller, short-term projects.

- Cycle Time: The time it takes to complete one production cycle affects overall costs. Faster cycle times can reduce labor and machine usage expenses.

How DTG Injection Molding Optimizes Costs

- Efficient Design: Our experienced engineers work with you to optimize your design, reducing complexity and material waste while maintaining product integrity.

- Material Expertise: We help you select the most cost-effective material that meets your product’s requirements, balancing quality and cost.

- Advanced Technology: Utilizing state-of-the-art machinery and automation, we enhance production efficiency, reducing cycle times and labor costs.

- Scalable Solutions: Whether you need a small prototype run or a high-volume production, we provide scalable solutions to fit your budget.

Typical Cost Breakdown

- Design and Prototyping: Costs associated with initial design, prototyping, and testing.

- Tooling: The cost of creating the injection mold, which can vary based on complexity and material.

- Material Costs: Expenses related to the raw materials used in the production process.

- Production: Costs incurred during the actual molding process, including labor, machine time, and overhead.

- Post-Processing: Additional steps such as assembly, finishing, and quality inspection.

Getting an Accurate Injection Molding Quote

- Contact Us: Reach out to us via our online form, email, or phone to discuss your project requirements.

- Provide Details: Share your design files, material preferences, production volume, and any other relevant information.

- Receive a Quote: We will analyze your project and provide a detailed, competitive quote that includes a clear cost breakdown.

- Consultation: Our team will discuss the quote with you, offering insights and suggestions to optimize costs without compromising on quality.

Why Choose DTG Injection Molding?

- Transparent Pricing: We believe in clear, upfront pricing with no hidden fees.

- Expert Consultation: Our knowledgeable team provides guidance to help you make cost-effective decisions.

- High-Quality Standards: We ensure that every project meets the highest standards of quality and precision.

Contact Us Today

Ready to understand the cost of injection molding for your project? Contact DTG Injection Molding today to discuss your requirements and receive a fast, accurate quote. Let us help you bring your vision to life with our expert injection molding services.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

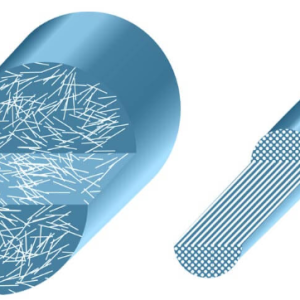

Superior Long Fiber Injection Molding Services from DTG Injection Molding

Read more -

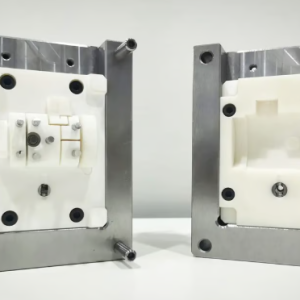

Revolutionize Your Manufacturing with 3D Printed Injection Molds

Read more -

Ejector Pins in Injection Molding: Essential Components for Precision

Read more -

Small Scale Plastic Injection Molding

Read more -

China Mould Maker Custom Automobile Plastic Parts

Read more -

Injection Molded Plastic Containers

Read more