Changing an injection mold involves several steps to ensure a smooth transition from one mold to another while maintaining production efficiency and minimizing downtime. Here’s a comprehensive guide on how to change an injection mold:

Preparing for Mold Change

- Schedule Maintenance Downtime:

- Plan mold changes during scheduled maintenance windows or downtime periods to minimize production disruption.

- Coordinate with production planning and scheduling teams to ensure minimal impact on overall production schedules.

- Gather Necessary Tools and Equipment:

- Prepare all required tools and equipment for mold change, including hoists or cranes for heavy molds, wrenches, screwdrivers, mold carts, and cleaning supplies.

- Safety Precautions:

- Ensure all safety protocols are followed, including lockout/tagout procedures to isolate energy sources and prevent accidental machine activation during mold change.

[elementor-template id=”4330″]

Step-by-Step Mold Change Procedure

- Machine Preparation:

- Stop the injection molding machine and allow it to cool down if necessary.

- Clean the machine and surrounding area to remove any residue or contaminants that could affect the new mold installation.

- Remove the Current Mold:

- Open the mold clamping unit and remove any auxiliary equipment (e.g., robots, sprue pickers) attached to the mold.

- Use appropriate tools to loosen and remove bolts or fasteners securing the mold to the machine platens.

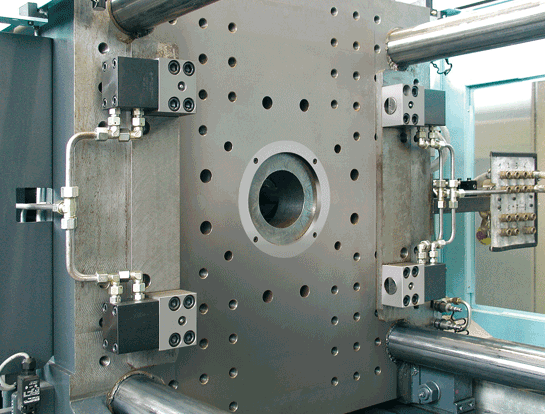

- Inspect and Clean the Machine:

- Inspect the machine platens for cleanliness and damage.

- Clean and lubricate the platens if necessary to ensure smooth installation of the new mold.

- Prepare the New Mold:

- Transport the new mold to the injection molding machine using a mold cart or hoist.

- Inspect the new mold for any damage or defects before installation.

- Install the New Mold:

- Position the new mold on the machine platens, aligning it carefully with the nozzle and sprue bushing.

- Securely fasten the mold using bolts or fasteners, ensuring even clamping force across the mold.

- Connect Auxiliary Equipment:

- Reattach any auxiliary equipment, such as robots or sprue pickers, to the new mold.

- Verify proper alignment and functionality of auxiliary components.

- Adjust Setup Parameters:

- Enter and verify mold-specific setup parameters in the machine control panel, including injection pressure, temperature profiles, and cycle times.

- Conduct dry runs or test shots to ensure proper functioning of the new mold and validate part quality.

- Run Production Tests:

- Initiate production runs with the new mold to verify part quality, dimensional accuracy, and cycle times.

- Monitor the injection molding process closely during initial production to identify and address any issues promptly.

- Document and Record:

- Maintain detailed records of mold changes, including setup parameters, test results, and any adjustments made during the process.

- Update production documentation and inform relevant personnel of the mold change completion.

Post-Mold Change Activities

- Monitor Production:

- Continuously monitor production after mold change to ensure stable operation and consistent part quality.

- Address any emerging issues or adjustments needed to optimize production performance.

- Perform Regular Maintenance:

- Schedule regular mold maintenance and cleaning to prolong mold life and prevent production disruptions.

- Implement preventive maintenance procedures to address wear and tear, lubrication, and mold storage conditions.

[elementor-template id=”4331″]

Conclusion

Changing an injection mold requires careful planning, preparation, and execution to maintain production efficiency and quality standards. By following a systematic mold change procedure and adhering to safety protocols, manufacturers can minimize downtime, optimize machine utilization, and ensure smooth transitions between different molds in injection molding operations

Related Conten: Custom Plastic Extrusions

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|