Acrylic Wine Glasses Manufacturer

As a leading Acrylic Wine Glasses Manufacturer, Xiamen DTG Tech Co., Ltd delivers shatter-resistant, food-grade, and elegantly designed acrylic wine glasses for global hospitality brands, restaurants, bars, events, wholesalers, and OEM/ODM private label projects. With over 20 years of engineering and injection molding experience, we support full customization—from mold design to mass production—ensuring high-clarity, lightweight, and durable wine glasses that meet international safety standards.

Our acrylic wine glasses are created for professionals who need reliable drinkware with a glass-like appearance, without the risk of shattering. Whether you are a hospitality supplier, an event planner, or a global distributor, we provide scalable solutions tailored to your market needs.

Why Choose DTG as Your Acrylic Wine Glasses Manufacturer

Durable, Lightweight & Food-Grade

Acrylic (PMMA) offers excellent transparency with up to 92% light transmission, making it visually comparable to glass while remaining lightweight and impact-resistant. Each acrylic wine glass we produce is safe for daily, long-term use and crafted using 100% BPA-free materials.

Perfect for Restaurants, Bars & Events

Our acrylic wine glasses are widely used in:

-

Restaurants & wine bars

-

Hotels & catering services

-

Weddings, outdoor events, resorts

-

Poolside parties & beach bars

-

Retail and promotional gift markets

OEM & ODM Capabilities

Whether you need a customized shape, a new product line, or full packaging design, DTG provides complete Acrylic Wine Glasses OEM and Acrylic Wine Glasses ODM services.

We offer:

-

Custom shapes & wall thickness

-

Custom colors (Pantone matching)

-

Logo printing & branding

-

Mold development for new designs

-

Small-batch prototyping & mass production

Certifications & Compliance

All acrylic wine glasses can comply with:

-

FDA

-

BPA-free requirements

-

EU 10/2011 (material dependent)

-

LFGB (recommended for Tritan products)

Material Comparison: Acrylic vs PC vs Tritan

Choosing the right material is critical for your product positioning. As both an Acrylic Wine Glasses Supplier and an experienced Plastic Injection Molding Factory, we provide all three materials depending on your target market.

Acrylic (PMMA) – High Aesthetic Appeal

-

★★★★★ clarity, closest to real glass

-

Lightweight, cost-effective

-

Suitable for events, weddings, gifts

-

Not recommended for high-alcohol beverages

Polycarbonate (PC) – Heavy-Duty Commercial Use

-

Extremely high impact resistance

-

Heat-resistant and dishwasher-safe

-

Ideal for restaurants, bars, hotels

Tritan – Premium, BPA-Free, Luxury Market

-

Crystal-clear, durable, chemical-resistant

-

100% BPA-free, recyclable

-

Perfect for premium brands & OEM/ODM projects

Wine Glass Material Comparison

| Comparison Item | Acrylic (PMMA) | Polycarbonate (PC) | Tritan (Copolyester) |

|---|---|---|---|

| Clarity / Appearance | ★★★★★ Highly transparent, glass-like | ★★★★☆ Slight bluish tint | ★★★★★ Crystal-clear, colorless, premium glass-like |

| Impact Resistance | ★★☆☆☆ Breakable but stronger than glass | ★★★★★ Extremely impact-resistant, almost unbreakable | ★★★★☆ High-strength, durable |

| Scratch Resistance | ★★★☆☆ Hard but prone to fine scratches | ★★☆☆☆ Easy to scratch, can become cloudy | ★★★★☆ Better than PC, more scratch-resistant |

| Typical Uses | Outdoor cups, wedding cups, pool/beach cups, promotional gifts | Barware, restaurant cups, hotel drinkware, heavy-duty commercial use | Premium homeware, high-end hotels, luxury outdoor cups, OEM brand cups |

| Advantages | – Ultra-transparent – Low cost – Lightweight – Ideal for bulk promotional gifts |

– Strongest impact resistance – Resistant to alcohol & heat – Dishwasher-safe (commercial use) |

– BPA-free, highest safety – High clarity – Scratch & alcohol-resistant – Glass-like premium feel |

| Disadvantages | – Not resistant to alcohol (spirits may cause cracks) – Not chemical-resistant – Not suitable for commercial use |

– Easily scratched – Long-term use may cause clouding – Traditional PC may contain BPA (must specify BPA-free) |

– Highest cost – Import tariffs may apply (market-dependent) |

| Precautions | – Avoid spirits – Do not soak in harsh cleaners – Recommend hand wash |

– Must specify BPA-Free for EU/US export – Protect against scratches in packaging |

– Use original material to avoid counterfeit Tritan – Dishwasher safe, avoid rough contact |

| Target Users / Markets | Promotional gift suppliers, wedding supplies, outdoor gear brands, event planners | Restaurant suppliers, barware wholesalers, hotel buyers, beverage chains | High-end homeware brands, imported EU/US brands, luxury hotels, premium gift industry, ODM clients |

| Price Level | ★ (Lowest) | ★★☆ (Medium) | ★★★★☆ (Highest) |

| Eco / Health Safety | ✔ BPA-Free △ Limited recyclability |

✘ Usually contains BPA ✔ BPA-Free version available |

✔ 100% BPA-Free ✔ Recyclable, food-grade |

| Material Testing Standards (Export) | – FDA (moderate) – EU 10/2011 (difficult) – LFGB not recommended |

– FDA – EU 10/2011 – NSF – BPA-Free declaration may be needed |

– FDA – LFGB (best) – EU 10/2011 – Prop 65 (best) |

Acrylic Wine Glasses Mold Design Manufacturer

A high-quality acrylic wine glass starts with a high-precision mold. As a professional mold design manufacturer, DTG offers in-house engineering support to optimize your design for mass production.

Our Mold Design Advantages

-

Advanced CAD & CAE analysis

-

Optimized cooling channels for clarity

-

Durable steel molds for long production life

-

Multi-cavity molds for high-volume efficiency

Our Mold Design + Injection Molding services make us the preferred Acrylic Wine Glasses Plastic Injection Molding Factory for global brands seeking long-term reliability.

Complete Production Process: From Concept to Finished Wine Glasses

1. Mold Design

We begin by analyzing your CAD drawings or sketches, adjusting wall thickness, draft angles, and structure for manufacturability.

2. Prototype Manufacturing

Prototypes are produced via soft tooling or low-volume molds to confirm:

-

Ergonomics

-

Capacity

-

Balance

-

Aesthetic details

3. 3D Printing (Fast Sampling)

High-resolution 3D printing helps validate your design before finalizing tooling.

4. Mold Manufacturing

Our workshop includes:

-

CNC machining centers

-

Wire EDM & sink EDM

-

Precision polishing

-

Multi-cavity assembly

5. Injection Molding

Your chosen material (Acrylic / PC / Tritan) undergoes precision molding with strict process control to ensure clarity and durability.

6. Decoration & Surface Finishing

We provide professional decoration options:

-

Screen printing

-

Pad printing

-

Laser engraving

-

UV full-color printing

-

Gold/silver metallic rims: PVD, hot stamping, or spray coating

7. Sample Confirmation & Mass Production

Once samples are approved, full-scale production begins with strict quality control under ISO 9001:2015 standards.

Surface Texture & Branding Options

Injection-Molded Vertical Textures

Ribbed or patterned textures are built directly into the mold for:

-

Permanent durability

-

No peeling or fading

-

Unique premium appearance

Branding Options

-

Screen Printing: Cost-effective for simple logos

-

Pad Printing: Ideal for curved surfaces

-

UV Printing: High-resolution, full-color graphics

-

Laser Engraving: Permanent, elegant finish

Premium Metallic Rim Options

-

PVD vacuum coating

-

Hot foil stamping

-

Metallic spray coating

Factory Capabilities & Certifications

DTG operates a modern injection molding facility equipped with:

-

Injection machines (80T–800T)

-

CNC machining centers

-

Milling, grinding, lathe equipment

-

Wire & sink EDM

-

EOS + HP MJF 5210 + SLS 3D printing

-

ISO 9001:2015-certified management

We handle:

-

Industrial product prototyping

-

Mold fabrication

-

Small-batch & mass injection molding

-

Assembly and decoration

Our capabilities allow us to deliver consistent results for projects of any scale.

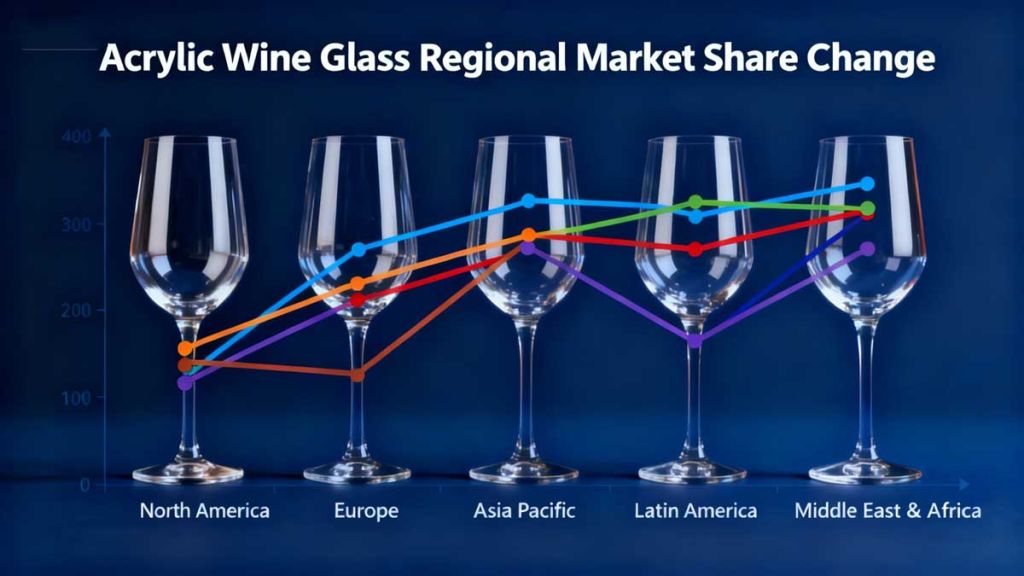

Market Outlook: Acrylic Wine Glasses Demand Continues to Grow

Strong Demand Driven by Multiple Markets

-

Outdoor lifestyle growth (picnic, camping, poolside)

-

Hotel & restaurant needs for unbreakable drinkware

-

Event planning & weddings

-

Corporate gifts & promotional items

-

Premium household drinkware

Why Acrylic Wine Glasses Are Increasingly Popular

-

Lightweight & shatter-resistant

-

More sustainable than disposables

-

Cost-effective for large-scale events

-

Safe and reusable

Tritan and PC are gaining traction in high-end and commercial markets, while Acrylic remains the top choice for outdoor and event categories.

B2B FAQ – Acrylic / Plastic Wine Glass Production

1. What materials do you offer?

PC, PCTG, PS, PMMA, and AS.

2. Can you make custom colors?

Yes—Pantone color customization is available.

3. Do you support 100% custom designs?

Yes. We deliver custom-mold samples within ~40 days.

4. Do you offer factory-direct pricing?

Yes—we are a direct manufacturer.

5. Where can your acrylic wine glasses be used?

Hotels, restaurants, bars, weddings, events, retail, and home.

6. Are the glasses safe for daily use?

Yes—materials like PS, PMMA, AS, and PCTG are BPA-free.

7. What is your production lead time?

-

New mold: ~35–40 days

-

Existing mold + custom color: 5 days

-

Ready-made samples: 2 days

8. What are your core advantages?

20+ years experience, strong engineering, mold design, and one-stop manufacturing.

9. What if we need processes you don’t provide?

We collaborate with long-term partner factories.

10. Do you provide free samples?

Yes—only shipping cost is required.

11. Payment terms?

Bank transfer (corporate) and Western Union (personal).

Contact Us – Start Your Custom Acrylic Wine Glass Project

Looking for a reliable Acrylic Wine Glasses Manufacturer with strong OEM/ODM capability?

Contact us today for a free consultation and sample support.

👉 Send your drawings or requirements to start your project!

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|