Home » Case Products » Polypropylene Plastic Injection Molding

Polypropylene Plastic Injection Molding

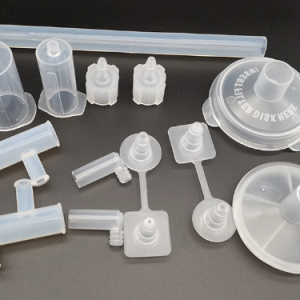

Welcome to our Polypropylene Plastic Injection Molding services, where versatility meets reliability. Polypropylene (PP) is a versatile thermoplastic known for its excellent chemical resistance, low density, and high impact strength, making it an ideal choice for a wide range of applications. Whether you need durable components for automotive, packaging, consumer goods, or industrial equipment, our Polypropylene Injection Molding solutions are tailored to meet your specific requirements.

Key Features:

- Chemical Resistance: Polypropylene exhibits excellent resistance to a wide range of chemicals, acids, bases, and solvents, making it suitable for applications exposed to harsh environments or corrosive substances.

- Low Density: With its low density, Polypropylene offers lightweight yet durable solutions, reducing overall part weight and material costs while maintaining strength and structural integrity.

- High Impact Strength: Polypropylene possesses high impact resistance, providing excellent toughness and durability in demanding applications, such as automotive components, packaging, and consumer goods.

- Versatility: Injection molding allows for the production of a wide range of complex shapes, intricate details, and custom designs with ease, making Polypropylene suitable for diverse applications across various industries.

Applications:

Our Polypropylene Plastic Injection Molding solutions find applications across a multitude of industries, including:

- Automotive: Interior components, dashboard panels, bumper fascias, and HVAC ducts.

- Packaging: Containers, caps, closures, crates, and packaging trays for food, beverage, and industrial products.

- Consumer Goods: Housewares, appliances, toys, furniture components, and sporting goods.

- Industrial Equipment: Housings, enclosures, panels, and components for machinery, equipment, and tools.

Benefits:

- Chemical Resistance: Polypropylene resists a wide range of chemicals, including acids, alkalis, and solvents, making it suitable for applications requiring resistance to chemical exposure or corrosion.

- Lightweight: Polypropylene’s low density makes it an excellent choice for lightweight components, reducing material costs and energy consumption while maintaining strength and durability.

- Cost-Effectiveness: Injection molding offers high production efficiency, fast cycle times, and minimal material waste, resulting in cost-effective manufacturing solutions for large-volume production runs.

- Design Flexibility: Injection molding enables the production of complex geometries, thin walls, and intricate features with high precision, allowing for customization and optimization of part designs to meet specific application requirements.

Why Choose Us?

- Expertise: With years of experience in plastic injection molding, we have the knowledge, skills, and resources to deliver high-quality Polypropylene parts that meet the most demanding requirements.

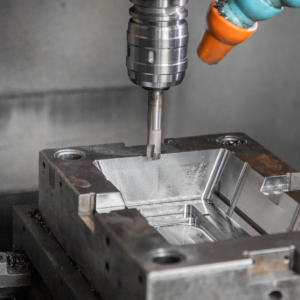

- Advanced Equipment: Our state-of-the-art injection molding machines and tooling are equipped with the latest technology to ensure precise molding, consistent quality, and efficient production.

- Quality Assurance: We adhere to strict quality control measures throughout the manufacturing process to ensure that every part meets the highest standards of performance, reliability, and safety.

Partner with us for your Polypropylene Plastic Injection Molding needs, and let us help you bring your innovative designs to life with durable, cost-effective parts. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Rapid Prototyping Aluminium: Fast, High-Precision Aluminium Prototypes for Your Product Development

Read more -

Plastic Injection Blow Molding

Read more -

High-Quality Metal Injection Molds at DTG Injection Molding

Read more -

Injection Molded Plastic Packaging

Read more -

Metal Prototype Fabrication: Precision Engineering for High-Performance Prototypes

Read more -

Custom Plastic Boxes Tailored to Your Business Needs

Read more