Home » Case Products » High Volume Plastic Injection Molding

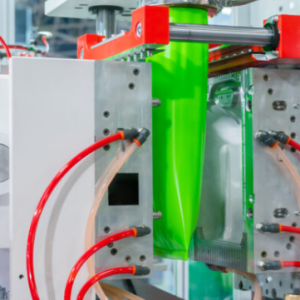

High Volume Plastic Injection Molding

Welcome to our high-volume plastic injection molding services. We specialize in efficiently producing large quantities of high-quality plastic components to meet the demands of your manufacturing needs. With our state-of-the-art equipment, streamlined processes, and commitment to excellence, we ensure cost-effective solutions and timely delivery for projects of any scale.

Our Expertise:

- Advanced Machinery: We employ a fleet of high-speed, high-capacity injection molding machines equipped with automated features to optimize cycle times and maximize production output.

- Tooling Expertise: Our team of skilled tooling engineers and technicians designs and fabricates precision molds tailored to the specific requirements of high-volume production, ensuring reliability and consistency.

- Process Optimization: We utilize scientific molding principles and advanced process control techniques to fine-tune parameters such as temperature, pressure, and injection speed, optimizing production efficiency and part quality.

Key Features:

- Fast Cycle Times: Our high-speed injection molding machines and optimized processes enable rapid cycle times, allowing for the production of large volumes of parts within short lead times.

- Consistent Quality: With stringent quality control measures in place, we maintain tight tolerances and uniformity across all parts, ensuring consistent quality and performance throughout the production run.

- Cost Efficiency: By leveraging economies of scale and implementing efficient production practices, we offer competitive pricing for high-volume projects, helping you minimize per-unit costs and maximize profitability.

Applications:

Our high-volume plastic injection molding services cater to a wide range of industries and applications, including:

- Consumer Products: Mass-produced consumer goods, packaging components, and household items.

- Automotive: Interior and exterior components, functional parts, and under-the-hood components.

- Electronics: Enclosures, connectors, housings, and components for electronic devices.

- Medical Devices: Disposable medical products, diagnostic equipment components, and device housings.

- Industrial Equipment: Functional parts, housings, enclosures, and components for machinery and equipment.

Benefits:

- Scalability: Our flexible production capabilities can accommodate varying order sizes, from tens of thousands to millions of parts, ensuring scalability to meet your business needs.

- Short Lead Times: With our efficient processes and fast cycle times, we can deliver large volumes of parts within compressed lead times, helping you meet tight deadlines and launch schedules.

- Cost-Effective Solutions: Our ability to optimize production efficiency and minimize waste results in cost-effective solutions for high-volume projects, providing excellent value for your investment.

Why Choose Us?

- Experience and Expertise: With years of experience in high-volume plastic injection molding, we have the knowledge and capabilities to deliver reliable, high-quality results for your production needs.

- Commitment to Quality: We adhere to strict quality standards and continuous improvement practices to ensure that every part meets your specifications and exceeds your expectations.

- Customer Satisfaction: We prioritize customer satisfaction and communication, working closely with you throughout the production process to address any concerns and deliver solutions that meet your requirements.

Partner with us for your high-volume plastic injection molding needs and experience the benefits of efficient, cost-effective production. Contact us today to discuss your project requirements or request a quote. We look forward to being your trusted manufacturing partner.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Polycarbonate Injection Molding: Durable and Impact-Resistant Solutions for High-Performance Applications

Read more -

Innovative Thermoforming for Efficient Custom Plastic

Read more -

Acetal Plastic Injection Molding

Read more -

Plastic Injection Molding Parts

Read more -

Injection Stretch Blow Molding Solutions

Read more -

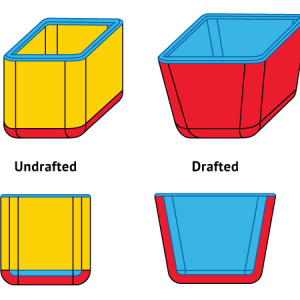

Mastering Draft Angle Injection Molding for Superior Results

Read more