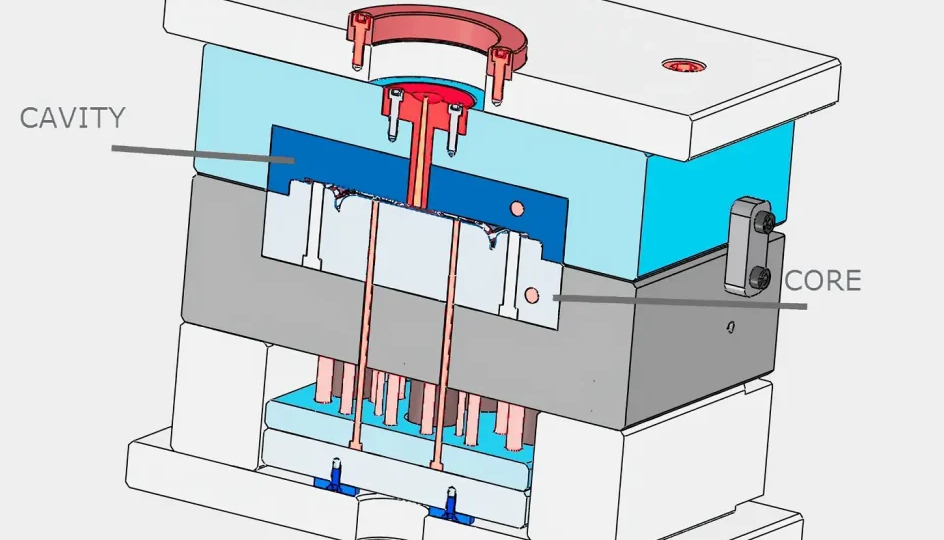

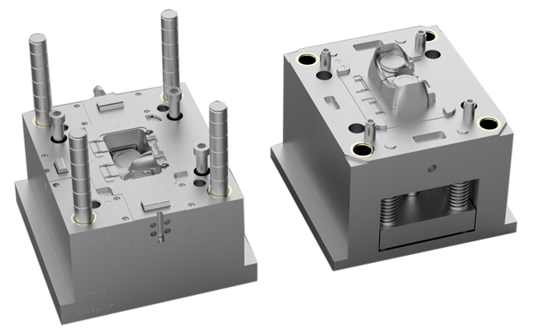

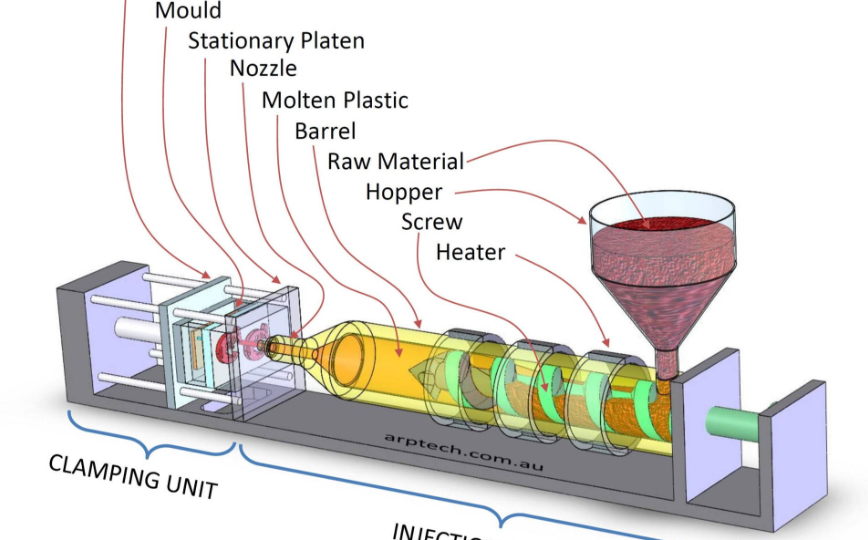

In injection molding, the term “cavity” refers to the hollow space or spaces within the mold where the molten plastic…

2024

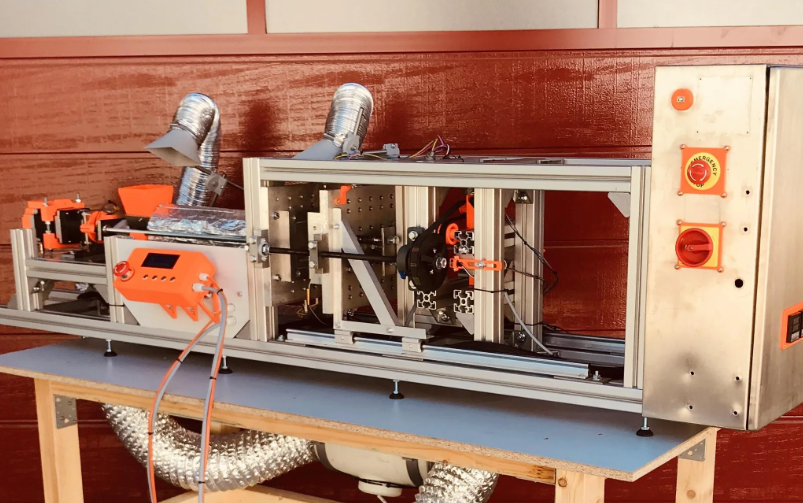

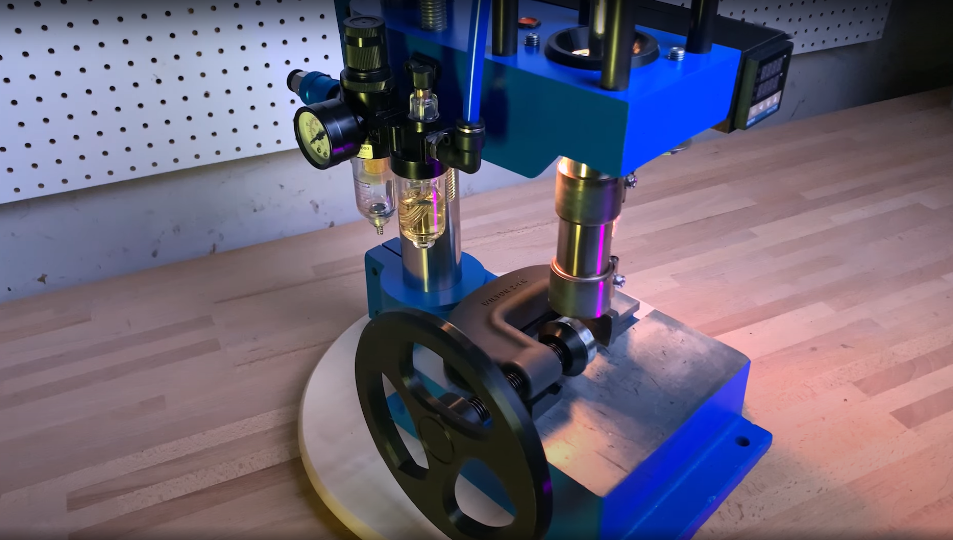

DIY plastic injection molding can be a rewarding and cost-effective way to produce small batches of plastic parts for personal…

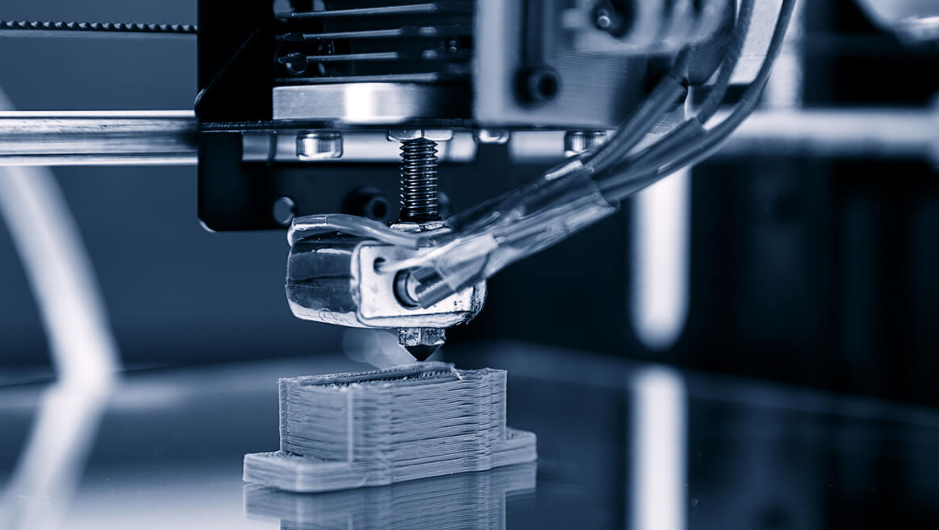

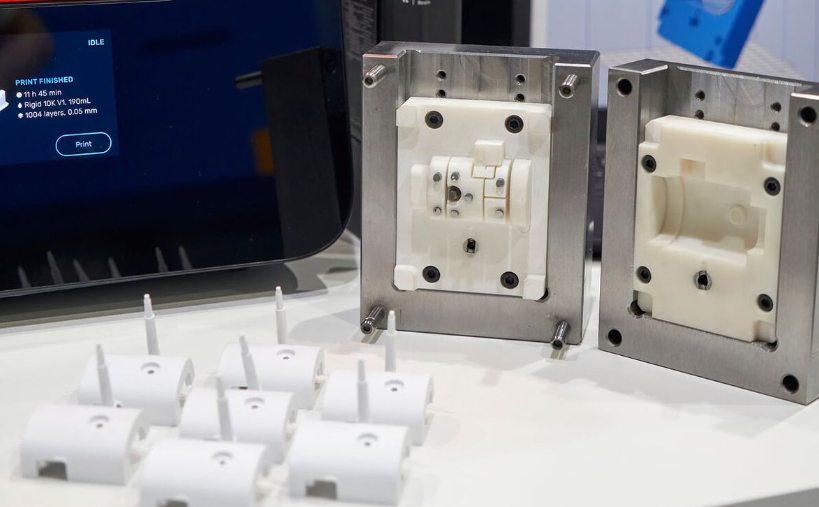

Injection molding and additive manufacturing are two distinct manufacturing processes, each with its own methods, advantages, and applications. Here’s a…

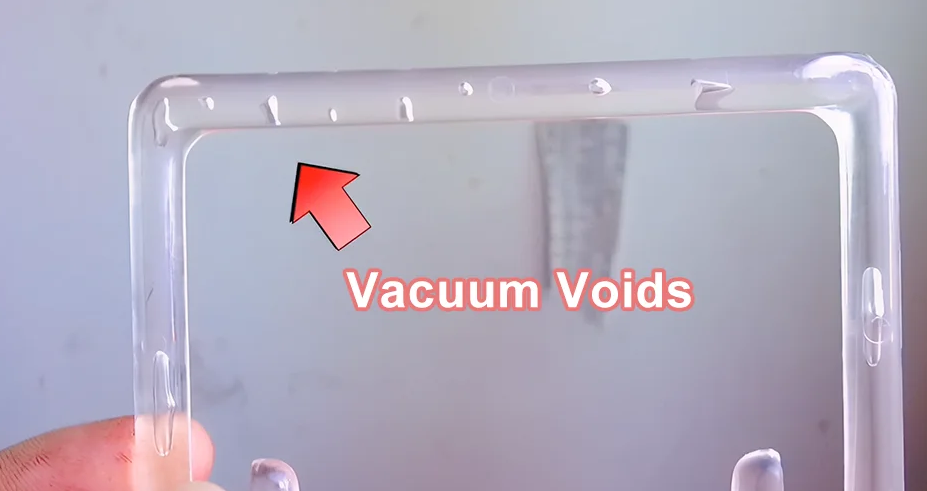

Voids in injection molded parts are unwanted hollow spaces or air pockets that can compromise the strength, appearance, and functionality…

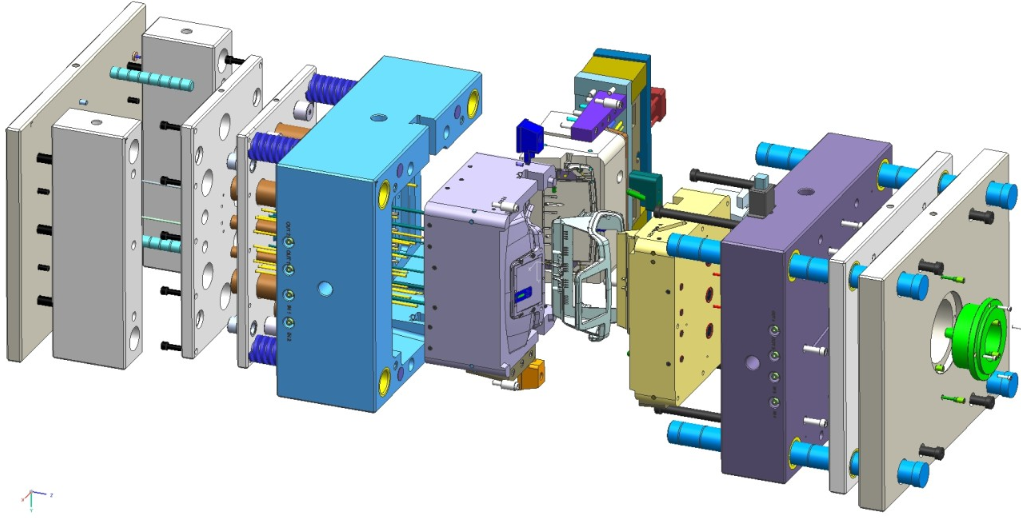

Making injection molds involves several steps, from designing the mold to fabricating and finishing it. Here’s a step-by-step guide to…

Bubbles in injection molded parts are a common defect that can compromise the appearance and structural integrity of the final…

Do-it-yourself (DIY) injection molding can be a cost-effective way to produce small batches of plastic parts without investing in expensive…

The cost-effectiveness of injection molding depends on several factors, including production volume, part complexity, material choice, and tooling costs. Here’s…

The cost of injection molding can vary significantly based on several factors, including the complexity of the part, the type…

Designing a mold for plastic injection molding involves several critical steps to ensure the final part meets specifications and is…