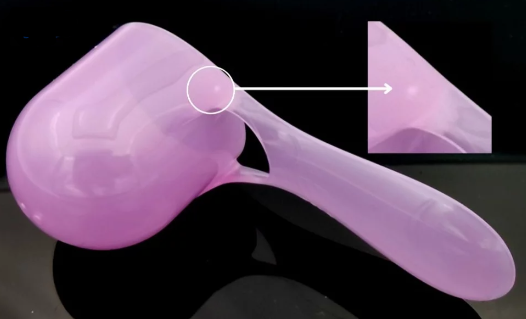

Sink marks are surface depressions or indentations that appear on injection molded components. These defects typically occur in thicker sections…

2024 July

Vacuum voids, also known as air pockets or gas pockets, are defects that occur within an injection-molded part. These voids…

Advantages of High Sprue Pressure Disadvantages of High Sprue Pressure Balancing Sprue Pressure In summary, while high sprue pressure can…

Flexible tubing is typically produced using extrusion rather than injection molding. Here’s why extrusion is the preferred method: Extrusion Process…

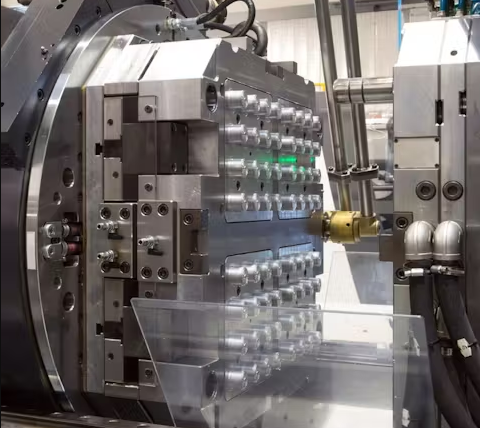

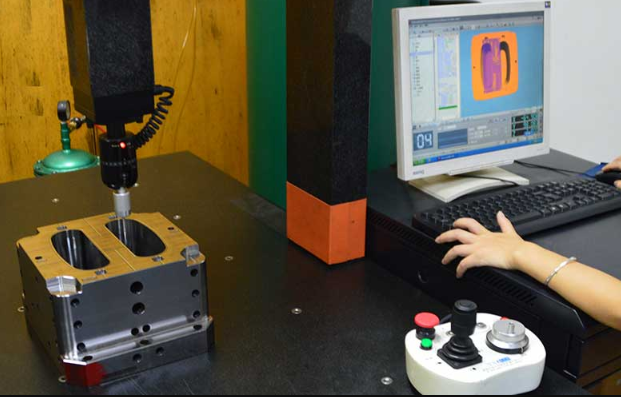

Injection molding inspection reports are critical documents used to ensure that molded parts meet specified quality standards and customer requirements….

Aluminum is a popular material for making molds used in injection molding, particularly for certain applications. Here are the advantages…

Yes, acetal plastic, also known as polyoxymethylene (POM), is commonly used for injection molding. Acetal is a highly crystalline thermoplastic…

The cost comparison between 3D printing and injection molding depends on several factors, including the volume of parts, complexity of…

Silicone injection molding is used to create parts that require high precision and excellent material properties such as flexibility, heat…

The comparison between 3D printing and injection molding depends on several factors, including production volume, cost, material properties, and the…