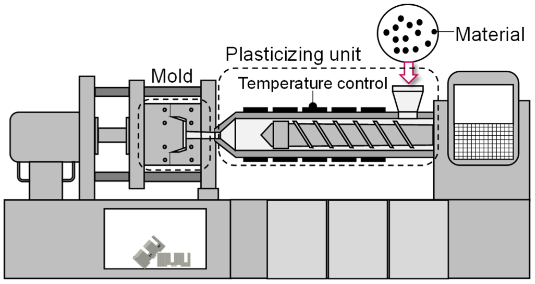

The cost comparison between extrusion and injection molding depends on various factors such as the complexity of the parts, the…

2024 July

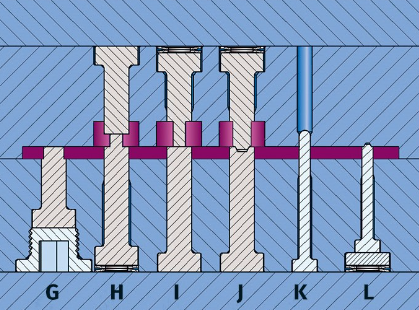

Core pin bending in injection molding can result from several factors related to the process, materials, and equipment. Here are…

Increasing shrinkage in injection molding is generally not a desired outcome, as it can lead to dimensional inaccuracies and defects…

Increasing the shot weight in injection molding involves optimizing various aspects of the process, including machine settings, mold design, and…

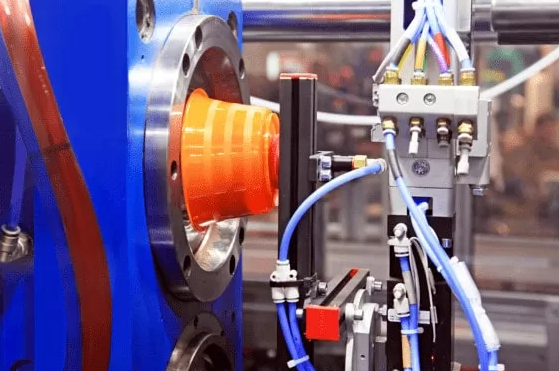

Increasing productivity in injection molding involves optimizing various aspects of the process, including machine efficiency, cycle time reduction, material handling,…

Hiding screws in an injection molded part can improve the aesthetic appeal and functionality of the product. Here are some…

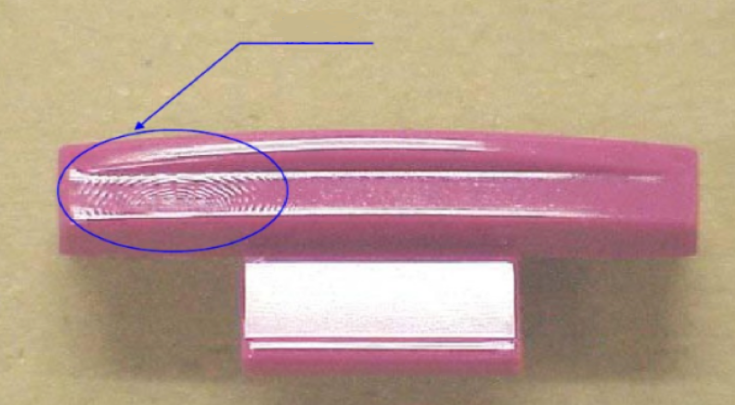

Silver streaks, also known as splay, are a common defect in injection molding characterized by shiny, silver-like streaks on the…

Cleaning injection molding machines and molds is a critical maintenance task to ensure high-quality production, minimize downtime, and extend the…

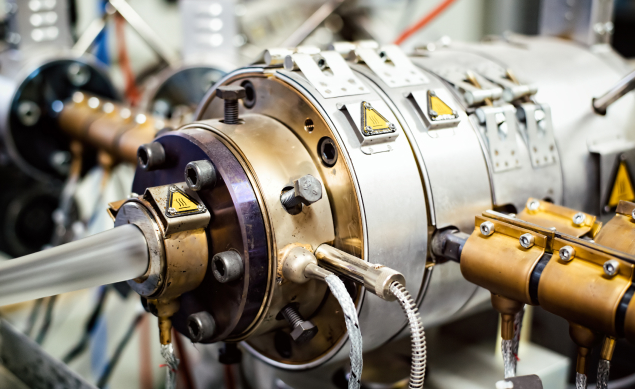

An injection molder screw is a critical component of the injection molding machine, responsible for melting, mixing, and conveying the…

A setter, also known as a mold setter or setup technician, plays a crucial role in the injection molding process….