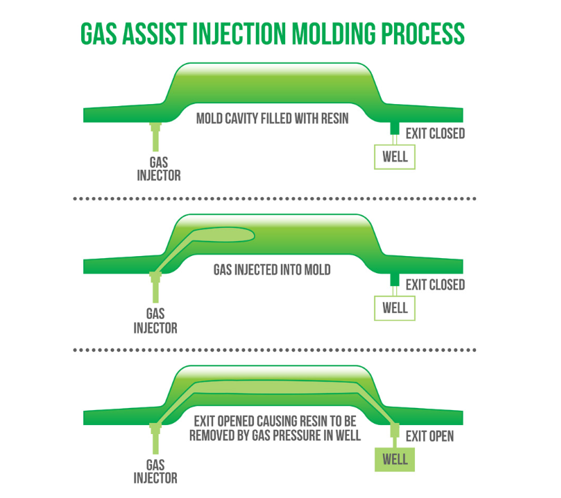

Gas assist injection molding is a specialized injection molding process that uses gas (usually nitrogen) to create hollow sections or…

2024 June

In injection molding, a draft angle refers to the slight taper or angle incorporated into the vertical walls of a…

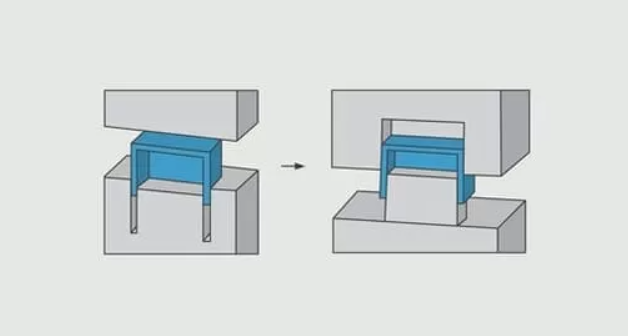

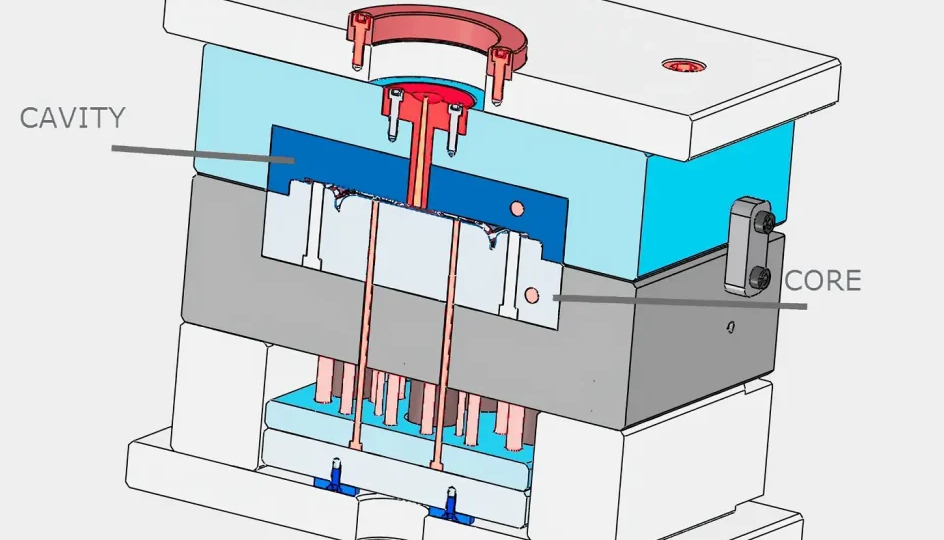

In injection molding, the terms “core” and “cavity” refer to the two halves of the mold that come together to…

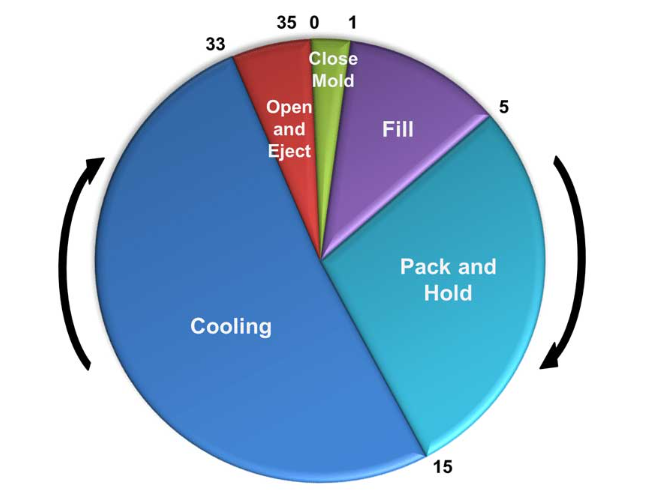

Cooling time in injection molding is the period during which the molten plastic solidifies and cools down inside the mold…

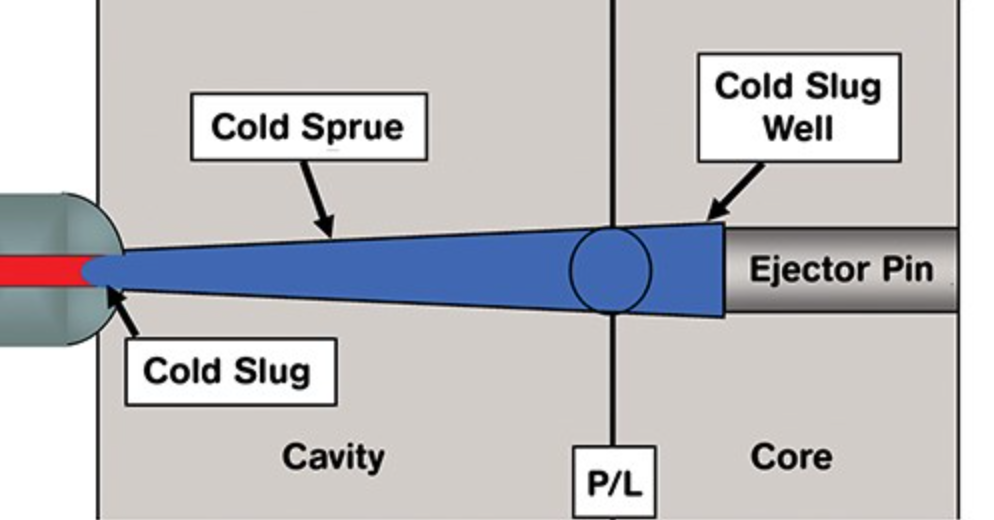

A cold slug well is an important feature in the design of an injection mold. It serves a specific function…

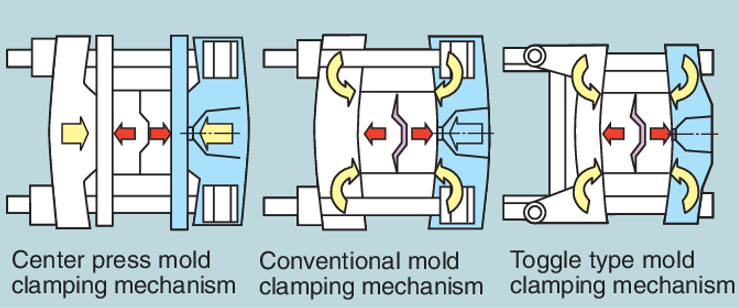

Clamping force in injection molding is the pressure applied by the injection molding machine to hold the two halves of…

In injection molding, the term “cavity” refers to the hollow space or spaces within the mold where the molten plastic…

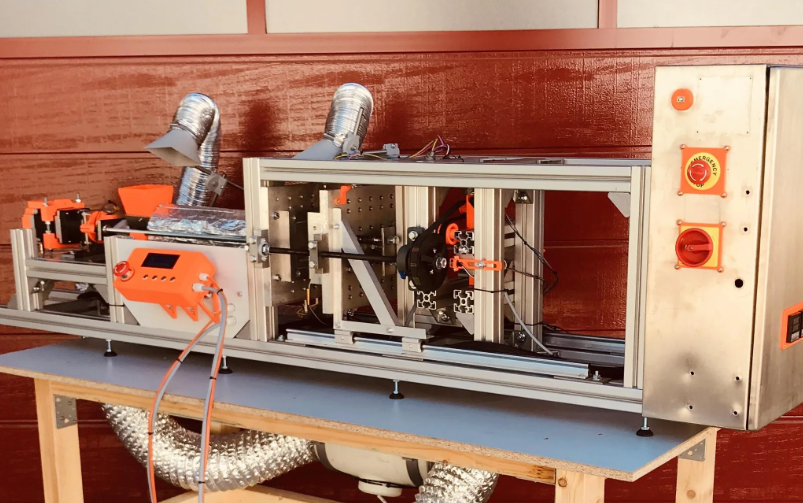

DIY plastic injection molding can be a rewarding and cost-effective way to produce small batches of plastic parts for personal…

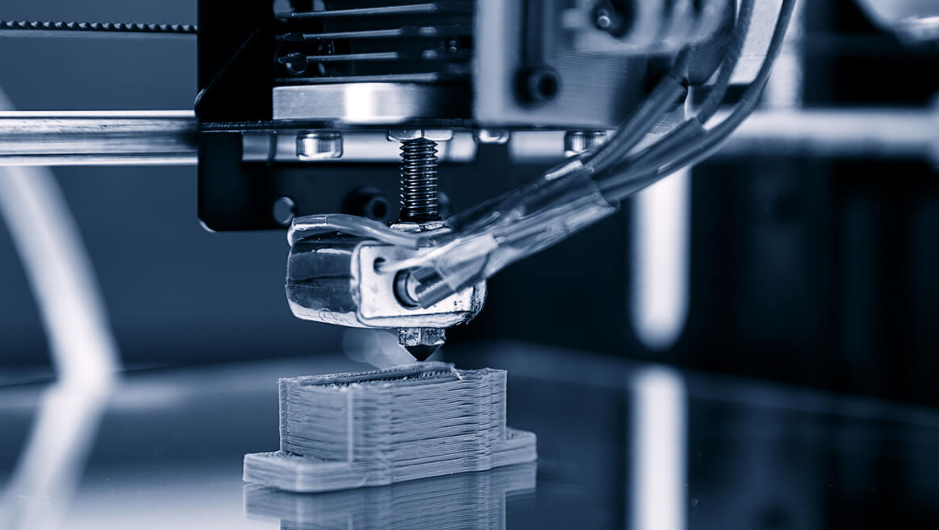

Injection molding and additive manufacturing are two distinct manufacturing processes, each with its own methods, advantages, and applications. Here’s a…

Voids in injection molded parts are unwanted hollow spaces or air pockets that can compromise the strength, appearance, and functionality…