In the world of high-performance plastics, PPE injection molding stands out as a superior choice for manufacturers across industries from automotive to electronics. If you’re looking for a way to produce complex, durable plastic parts efficiently, understanding the benefits of PPE injection molding can give you a serious edge.

What is PPE Injection Molding

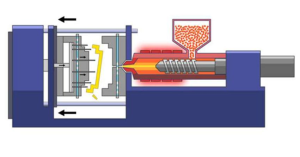

PPE (Polyphenylene Ether) is a high-performance engineering thermoplastic known for its excellent thermal stability, electrical insulation, and low moisture absorption. When combined with the injection molding process, it allows manufacturers to create intricate plastic components with high precision and consistency.

Top Advantages of PPE Injection Molding

1. Exceptional Material Properties

PPE is widely appreciated for its thermal resistance and structural integrity. When used in injection molding, PPE parts offer:

High heat resistance, ideal for components exposed to elevated temperatures

Electrical insulation, perfect for electronic housings and connectors

Dimensional stability, thanks to its low moisture absorption

Chemical resistance, withstanding acids, bases, and water without degrading

These properties make PPE injection molding a go-to choice in industries requiring durability and precision.

2. Greater Manufacturing Efficiency

Compared to traditional fabrication methods like machining or compression molding, PPE injection molding delivers:

Faster production cycles

Minimal post-processing

High repeatability and consistency

Once the mold is created, thousands or even millions of identical parts can be produced rapidly and reliably.

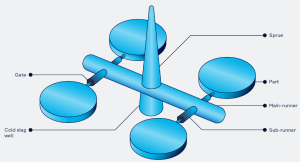

3. Design Flexibility and Complexity

Injection molding with PPE enables the production of complex and integrated parts that would be difficult or expensive to achieve with conventional methods. This makes it ideal for:

Lightweight designs with embedded features

High-precision parts for technical assemblies

Components that require fewer assembly steps

4. Cost-Effective for Mass Production

Though the upfront tooling costs for injection molding may seem high, the per-unit cost drops significantly with high-volume production. This makes PPE injection molding a cost-effective solution for:

Automotive components

Consumer electronics

Industrial-grade plastic parts

5. Reduced Material Waste

Traditional manufacturing often involves cutting away excess material. Injection molding, on the other hand:

Uses only the material needed

Produces less scrap

Allows for recycling of excess PPE plastic

This not only saves money but also supports sustainable production goals.

6. Automation-Ready Process

PPE injection molding integrates easily with automation and robotics, allowing for:

Increased production speed

Enhanced quality control

Lower labor costs

This makes it a future-proof option for smart manufacturing.

Summary of PPE Injection Molding vs Traditional Methods

PPE injection molding offers high heat resistance, design flexibility, fast production speed, low unit cost at scale, minimal material waste, and excellent compatibility with automation. Traditional methods often fall short in one or more of these areas, especially for high-volume or precision applications.

Conclusion: Is PPE Injection Molding Right for Your Project

If you’re working on a project that demands durable, high-precision plastic parts at scale, PPE injection molding is likely your best option. Its advantages in material performance, production efficiency, and cost make it far superior to traditional manufacturing techniques, especially when long-term reliability matters.