Why Is PPE Injection Molding Essential in Producing Medical and Industrial Safety Gear?

In today’s world, personal protective equipment (PPE) is critical in protecting workers, patients, and the general public. Whether in hospitals, construction zones, or manufacturing plants, reliable PPE can mean the difference between safety and exposure to serious hazards.

One of the most efficient and consistent methods of PPE production is injection molding. But why is PPE injection molding so essential? Let’s explore how this process is shaping the future of safety gear manufacturing.

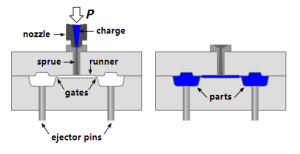

What Is PPE Injection Molding?

PPE injection molding is the process of manufacturing PPE components by injecting molten plastic into a mold. After cooling and solidifying, the part is ejected and ready for use. This method is used to produce items such as:

Face shields

Mask components

Goggles and visors

Respirator valves

Safety helmet parts

Medical device housings

Injection molding is preferred for PPE because it allows for high-volume, precise, and repeatable production—critical for items where performance and safety standards are non-negotiable.

5 Reasons Why Injection Molding Is Essential for PPE Production

1. High Precision and Repeatability

Each PPE item must meet stringent safety and regulatory requirements. Injection molding ensures that each part is manufactured with tight tolerances, reducing the risk of failure in the field.

2. Scalability for Mass Production

During emergencies—like pandemics or industrial accidents—demand for PPE can skyrocket. Injection molding supports fast and scalable manufacturing to meet large-scale needs.

3. Material Versatility

Common materials like polycarbonate, polypropylene, ABS, and medical-grade plastics are easily molded into durable, hygienic, and impact-resistant components, tailored to different environments.

4. Cost-Efficiency Over Time

Although the initial tooling investment is high, the cost per unit drops significantly in large production runs, making it ideal for both long-term supply and emergency stockpiling.

5. Customizability and Ergonomics

Injection molding allows manufacturers to include ergonomic designs, branding, and other functional features that improve user comfort and product effectiveness.

The Role of Injection Molding in Future PPE Innovation

As industries evolve and safety standards grow stricter, PPE injection molding continues to be a cornerstone technology in developing more effective, comfortable, and accessible safety gear.

Advancements like antimicrobial plastics, biodegradable resins, and AI-driven mold design are already improving the performance and sustainability of molded PPE products.