CNC cutting, an essential technology in modern manufacturing, stands for Computer Numerical Control cutting. This process utilizes computer-controlled machines to cut materials with precision and efficiency. From metals and plastics to wood and composites, CNC cutting is widely used in various industries to produce complex and accurate components. This article will delve into what CNC cutting is, how it works, its applications, and the benefits it offers.

What Is CNC Cutting?

CNC cutting refers to the automated process of cutting materials using CNC machines. These machines are programmed via computer software to follow specific paths and shapes, ensuring high precision and repeatability. CNC cutting can be performed on various materials, including metals, plastics, wood, and composites, making it versatile for different applications.

How Does CNC Cutting Work?

- Design Creation

- CAD Software: The process begins with creating a digital design of the part or component using Computer-Aided Design (CAD) software.

- CAM Software: The CAD design is then converted into a CNC program using Computer-Aided Manufacturing (CAM) software, which generates the necessary toolpaths for the cutting machine.

- Machine Setup

- Material Loading: The chosen material is securely loaded onto the CNC cutting machine’s bed or table.

- Tool Selection: Appropriate cutting tools (e.g., drills, end mills, laser cutters) are selected based on the material and design requirements.

- Cutting Process

- Programming: The CNC machine is programmed with the generated toolpaths, which guide the cutting tools along the specified paths.

- Execution: The machine executes the programmed instructions, cutting the material with high precision to create the desired shape and dimensions.

Types of CNC Cutting Machines

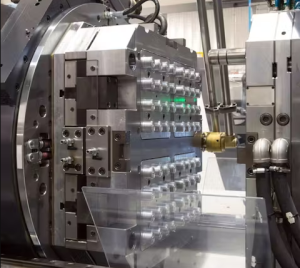

- CNC Milling Machines

- Operation: These machines use rotary cutters to remove material from a workpiece. They can perform various operations, such as drilling, milling, and tapping.

- Applications: Used in manufacturing parts for automotive, aerospace, and industrial equipment.

- CNC Laser Cutters

- Operation: Utilize a focused laser beam to cut or engrave materials with high precision.

- Applications: Commonly used in the electronics, signage, and jewelry industries.

- CNC Plasma Cutters

- Operation: Employ a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials.

- Applications: Ideal for cutting metals like steel, aluminum, and copper.

- CNC Waterjet Cutters

- Operation: Use a high-pressure jet of water, often mixed with an abrasive substance, to cut materials.

- Applications: Suitable for cutting a wide range of materials, including metals, stone, and composites.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Benefits of CNC Cutting

- Precision and Accuracy

- Tight Tolerances: CNC cutting machines can achieve extremely tight tolerances, ensuring parts are manufactured to exact specifications.

- Consistency: The automated process guarantees consistent quality across multiple parts.

- Efficiency and Productivity

- Speed: CNC machines operate at high speeds, significantly reducing production time.

- Automation: Once programmed, CNC machines can run continuously with minimal supervision, enhancing productivity.

- Versatility

- Material Range: CNC cutting is applicable to a wide range of materials, from metals and plastics to wood and composites.

- Complex Shapes: Capable of producing intricate and complex shapes that would be challenging with manual cutting methods.

- Cost-Effectiveness

- Reduced Waste: Precision cutting minimizes material waste, lowering overall production costs.

- Labor Savings: Automation reduces the need for skilled labor, further cutting costs.

Applications of CNC Cutting

- Automotive Industry

- Parts Manufacturing: Used for producing engine components, gears, and other critical parts with high precision.

- Aerospace Industry

- Component Fabrication: Essential for manufacturing aircraft parts that require tight tolerances and exceptional accuracy.

- Construction Industry

- Structural Elements: Utilized for cutting steel beams, panels, and other structural components.

- Electronics Industry

- Circuit Boards: CNC cutting is used to produce precise and intricate designs for electronic circuit boards.

- Furniture and Woodworking

- Custom Designs: Enables the creation of custom furniture pieces and intricate woodwork with high precision.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Conclusion

CNC cutting is a revolutionary technology that has transformed modern manufacturing. Its ability to cut various materials with high precision and efficiency makes it indispensable across multiple industries. By understanding the intricacies of CNC cutting, businesses can leverage its benefits to enhance production quality, reduce costs, and improve overall productivity.

Related Conten: CNC Mold Manufacturing