Top Benefits of Choosing PPE Injection Molding for Your Protective Equipment

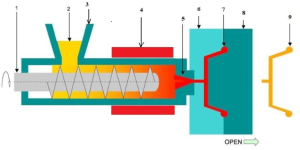

In today’s safety-conscious world, the demand for reliable and cost-effective protective equipment is higher than ever. One manufacturing process that has stood out in meeting this demand is PPE injection molding. This technique combines speed, precision, and consistency—making it ideal for producing high-quality personal protective equipment (PPE) at scale.

Here are the top benefits of choosing PPE injection molding for your protective equipment needs:

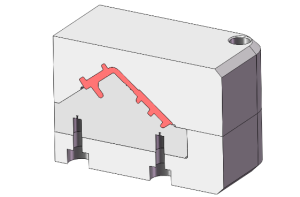

1. High Precision and Repeatability

PPE injection molding allows manufacturers to produce intricate designs and consistent shapes across large quantities. This is especially crucial for items like face shields, respirator components, and goggles, where exact fit and function are essential for safety. Once the mold is finalized, every unit produced will mirror the original with high accuracy.

2. Scalability and Cost Efficiency

One of the biggest advantages of PPE injection molding is the ability to scale production quickly. Once the mold is ready, thousands or even millions of units can be produced with minimal variable costs. This makes it a highly cost-effective method, especially for large-scale distribution during public health emergencies or commercial supply needs.

3. Material Versatility

PPE injection molding supports a wide range of materials, including medical-grade thermoplastics that are both durable and lightweight. This flexibility allows manufacturers to tailor the equipment based on the required performance—whether it’s chemical resistance, flexibility, or impact strength.

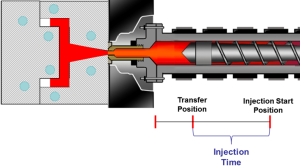

4. Faster Time-to-Market

Speed is critical in the PPE industry. With injection molding, once the tooling is set up, production cycles are extremely fast. This reduces lead time significantly, ensuring that products can be delivered to market—or into the hands of healthcare workers—quickly and efficiently.

5. Clean and Safe Production Standards

Modern PPE injection molding facilities are capable of adhering to strict hygiene and quality standards. The closed, automated nature of the process reduces contamination risks, which is vital for medical and protective gear production.

6. Custom Design Capabilities

Injection molding enables manufacturers to customize the design of PPE based on ergonomic or brand-specific needs. Whether it’s adding comfort-focused features, color options, or brand embossing, PPE injection molding offers exceptional design freedom without sacrificing efficiency.

Conclusion

Whether you’re developing PPE for industrial, healthcare, or consumer use, PPE injection molding offers a unique combination of precision, cost efficiency, speed, and safety compliance. It’s no wonder that top manufacturers across the globe are turning to this method to meet growing safety demands.

Looking to launch your own line of PPE products? Partner with a trusted PPE injection molding manufacturer to bring your vision to life—safely and efficiently.