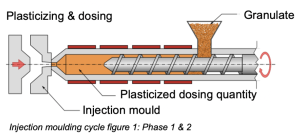

Understanding PPE Injection Molding

PPE injection molding is a manufacturing process where polyphenylene ether (PPE) plastic is melted and injected into molds to produce high-precision components. It is widely used in industries such as automotive, electronics, and medical devices because of its excellent thermal stability, dimensional accuracy, and chemical resistance.

Cost Reduction Benefits

Reduced Material Waste – Injection molding allows precise control over the amount of PPE used, minimizing waste and lowering material costs.

Lower Labor Costs – Automation in PPE injection molding reduces manual labor requirements, which decreases production expenses.

Fewer Defects – High-quality molds and consistent processing reduce errors and rework, saving both time and money.

Efficiency Improvement Advantages

High Production Speed – PPE injection molding can produce large quantities of parts quickly compared to traditional manufacturing methods.

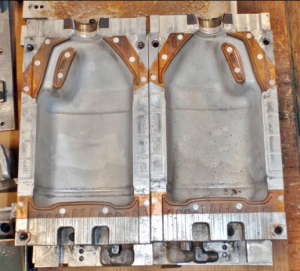

Consistency and Precision – Each part produced has uniform quality, which reduces assembly issues and downstream inefficiencies.

Design Flexibility – Complex geometries can be manufactured in one step, eliminating the need for multiple processes and assembly stages.

Conclusion

Investing in PPE injection molding can help businesses cut material and labor costs while streamlining production processes. By leveraging its speed, precision, and automation, manufacturers can improve overall efficiency without compromising product quality.