Starting a CNC (Computer Numerical Control) business can be a rewarding venture, combining technical skill with entrepreneurial spirit. With the increasing demand for precision parts across various industries, a CNC business offers vast potential for growth and profitability. This guide provides a step-by-step approach to help you launch a successful CNC business, from initial planning to execution and growth strategies.

Step 1: Conduct Market Research

- Identify Your Niche

- Industry Focus: Decide which industries you will serve, such as automotive, aerospace, medical, or consumer products.

- Specialization: Determine if you will specialize in a particular type of CNC machining, such as milling, turning, or 3D printing.

- Analyze Competitors

- Local Competitors: Identify existing CNC businesses in your area and analyze their services, pricing, and customer reviews.

- Market Gaps: Look for gaps in the market where you can offer unique services or superior quality.

- Understand Customer Needs

- Target Customers: Identify potential customers and their specific needs.

- Pain Points: Understand common challenges customers face and how your services can solve them.

Step 2: Develop a Business Plan

- Executive Summary

- Business Overview: Provide a brief overview of your business, including your mission statement and objectives.

- Unique Selling Proposition (USP): Highlight what sets your CNC business apart from competitors.

- Services Offered

- Core Services: List the primary CNC services you will offer.

- Additional Services: Include any value-added services, such as design assistance or prototyping.

- Marketing Strategy

- Branding: Develop a strong brand identity, including a logo and company colors.

- Online Presence: Create a professional website and leverage SEO to attract online traffic.

- Advertising: Utilize digital marketing, social media, and traditional advertising to reach potential customers.

- Financial Plan

- Startup Costs: Outline the initial costs, including equipment, software, and workspace.

- Revenue Projections: Estimate your expected revenue and break-even point.

- Funding Sources: Identify potential funding sources, such as loans, investors, or personal savings.

Step 3: Acquire Equipment and Software

- CNC Machines

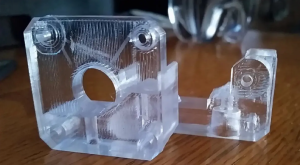

- Types of Machines: Depending on your services, purchase the necessary CNC machines, such as mills, lathes, or routers.

- Quality and Reliability: Invest in high-quality, reliable machines to ensure precision and minimize downtime.

- Software

- CAD/CAM Software: Purchase and familiarize yourself with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software.

- Inventory and Management Software: Implement software for managing inventory, scheduling, and customer orders.

Step 4: Set Up Your Workspace

- Location

- Space Requirements: Ensure your workspace has enough room for your machines, materials, and storage.

- Accessibility: Choose a location that is easily accessible to your target market.

- Infrastructure

- Power Supply: Ensure your workspace has the necessary power supply for your CNC machines.

- Ventilation and Safety: Set up proper ventilation, safety equipment, and fire protection systems.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Step 5: Hire and Train Staff

- Skilled Operators

- Experience: Hire experienced CNC operators who can produce high-quality work.

- Training: Provide ongoing training to keep your team updated on the latest techniques and technologies.

- Support Staff

- Sales and Marketing: Hire staff to handle sales, marketing, and customer service.

- Administrative Support: Employ administrative staff to manage bookkeeping, scheduling, and other office tasks.

Step 6: Launch Your CNC Business

- Soft Launch

- Trial Run: Conduct a trial run to ensure all systems and processes are working smoothly.

- Feedback: Gather feedback from initial customers to make any necessary adjustments.

- Grand Opening

- Promotion: Plan a grand opening event and promote it through various channels.

- Networking: Invite local business owners, potential customers, and industry professionals to build your network.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Step 7: Grow and Expand

- Customer Satisfaction

- Quality Control: Implement strict quality control measures to ensure customer satisfaction.

- Customer Service: Provide excellent customer service to build long-term relationships.

- Expand Services

- New Services: Continuously explore opportunities to expand your service offerings based on market demand.

- Technological Advancements: Stay updated on the latest CNC technologies and incorporate them into your business.

- Scale Operations

- Additional Equipment: Invest in additional machines and equipment to increase production capacity.

- New Markets: Explore opportunities to enter new markets and industries.

Conclusion

Starting a CNC business involves careful planning, investment in quality equipment, and a strong focus on customer satisfaction. By following this step-by-step guide, you can establish a successful CNC business and position yourself for long-term growth and profitability.

Related Conten: High Quality Prototype Plastic Injection Molding