The cost of injection molding can vary significantly depending on several factors. Here’s a detailed breakdown of the different costs involved in the injection molding process:

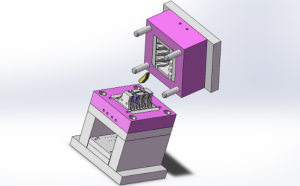

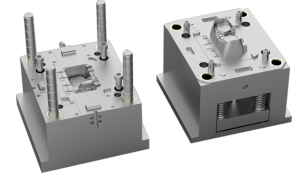

1. Mold Costs

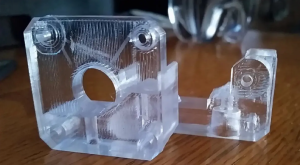

Initial Mold Costs

- Simple Molds: $3,000 to $10,000. These molds have basic features and fewer cavities.

- Complex Molds: $25,000 to over $100,000. These include multiple cavities, intricate geometries, and features like sliders or lifters.

- Aluminum: $3,000 to $20,000. Easier to machine, suitable for low to medium production volumes.

- Steel: $20,000 to $100,000 or more. More durable and suitable for high-volume production, but harder to machine.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

2. Production Costs

Material Costs

- Thermoplastics: $1 to $5 per pound, depending on the type of plastic.

- Specialty Plastics: Can be more expensive, up to $10 or more per pound.

Machine Time

- Hourly Rate: $50 to $200 per hour. The rate depends on the complexity of the machine and the cost of labor in the region.

- Cycle Time: The time to produce one part can range from a few seconds to a few minutes. Shorter cycle times are more cost-efficient.

3. Setup and Maintenance Costs

Setup Costs

- Setting up the machine and preparing for production can cost $500 to $1,500. This includes calibrating the machine, installing the mold, and testing the setup.

Maintenance Costs

- Regular maintenance is crucial to ensure the longevity and performance of the mold and machine. This can range from $1,000 to $5,000 annually, depending on usage and complexity.

4. Per-Unit Costs

Low-Volume Production (1,000-10,000 units)

- Higher per-unit cost due to the significant impact of the initial mold cost.

- Estimated per-unit cost: $5 to $50, depending on part complexity and material.

Medium-Volume Production (10,000-100,000 units)

- Lower per-unit cost as the initial mold cost is spread over more units.

- Estimated per-unit cost: $1 to $5.

High-Volume Production (100,000+ units)

- Lowest per-unit cost due to economies of scale.

- Estimated per-unit cost: $0.10 to $2.

5. Additional Costs

Design and Engineering

- Costs for designing and engineering the mold can range from $1,000 to $5,000. This includes CAD design and simulations to ensure the mold works correctly.

Quality Control

- Ensuring the parts meet quality standards might add additional costs, such as inspection equipment and labor. This can be $0.10 to $1 per part.

Shipping and Handling

- Costs to transport the mold and the finished parts. This varies based on distance and shipping method but can add $0.05 to $0.50 per part.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Example Cost Breakdown

For a mid-sized, moderately complex part with a production volume of 50,000 units:

Initial Costs

- Mold Design and Engineering: $5,000

- Single-Cavity Aluminum Mold: $15,000

Production Costs

- Material Cost: $2 per pound x 1 pound per part x 50,000 parts = $100,000

- Machine Time: $75 per hour x 1 minute per part x 50,000 parts / 60 = $62,500

- Setup Costs: $1,000

Total Cost

- Initial Mold Costs: $20,000

- Production Costs: $163,500

Per-Unit Cost Calculation

- Total Cost: $183,500

- Per-Unit Cost: $183,500 / 50,000 units = $3.67 per part

Conclusion

Injection molding can be expensive, especially when considering the initial investment for molds. However, it becomes cost-effective for high-volume production due to lower per-unit costs. The total expense depends on the complexity of the mold, the material used, production volume, and additional factors like design and maintenance. By understanding these costs, businesses can better plan and manage their injection molding projects to ensure cost efficiency and quality.

Related Conten: Prototype Injection Molding / Prototype Manufacturing