3D printing, also known as additive manufacturing, involves creating three-dimensional objects from a digital file by layering materials in succession. Here’s a detailed explanation of how the 3D printing process works:

Key Steps in the 3D Printing Process

- Creating a 3D Model:

- Design Software: The process begins with creating a digital 3D model using computer-aided design (CAD) software. Models can also be created by 3D scanning an existing object.

- File Format: The model is saved in a format such as STL (stereolithography), OBJ, or AMF (Additive Manufacturing File), which is used to describe the surface geometry of a 3D object.

- Slicing the Model:

- Slicing Software: The 3D model is imported into slicing software, which converts the model into a series of thin layers and generates the G-code. This G-code contains instructions for the 3D printer on how to construct each layer.

- Layering: The slicing software divides the model into horizontal layers, calculating the path the printer’s nozzle or laser will follow to create each layer.

- Setting Up the 3D Printer:

- Material Loading: The printing material (such as plastic filament, resin, powder, or metal) is loaded into the printer.

- Calibration: The printer is calibrated to ensure accurate layer deposition. This may include bed leveling and setting the correct nozzle height.

- Printing Process:

- Layer-by-Layer Construction: The printer starts building the object layer by layer, following the G-code instructions.

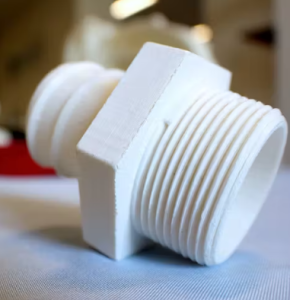

- FDM (Fused Deposition Modeling): A filament of thermoplastic material is melted and extruded through a heated nozzle, building the object layer by layer.

- SLA (Stereolithography): A UV laser cures liquid resin into solid plastic, layer by layer.

- SLS (Selective Laser Sintering): A laser fuses powdered material layer by layer.

- DMLS/SLM (Direct Metal Laser Sintering/Selective Laser Melting): Similar to SLS but uses metal powders, the laser melts the powder to create metal parts.

- Adhesion and Support: Some complex models may require support structures to be printed along with the object to ensure stability during printing.

- Layer-by-Layer Construction: The printer starts building the object layer by layer, following the G-code instructions.

- Post-Processing:

- Removing Supports: Any support structures are removed, and the object may be cleaned, sanded, or polished.

- Curing: For processes like SLA and DLP (Digital Light Processing), the printed object may require additional curing under UV light to fully harden.

- Finishing Touches: Additional finishing processes, such as painting, coating, or assembling multiple printed parts, may be applied.

Applications of 3D Printing

- Prototyping: Rapid creation of prototypes for design validation and testing.

- Manufacturing: Production of end-use parts, custom components, and complex geometries that are difficult to achieve with traditional manufacturing methods.

- Medical: Custom prosthetics, implants, anatomical models, and surgical instruments.

- Aerospace: Lightweight and complex parts for aircraft and spacecraft.

- Consumer Products: Customizable products like jewelry, toys, and home decor.

Advantages of 3D Printing

- Complex Geometries: Ability to produce intricate and complex shapes.

- Customization: Easily customizable for personalized products.

- Material Efficiency: Minimal waste compared to subtractive manufacturing.

- Rapid Prototyping: Quick turnaround from design to physical object.

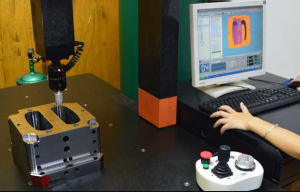

Your Partner in Custom Injection Molding

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

References

- 3D Printing Basics – HowStuffWorks: Provides a general overview of how 3D printing works and its applications.

- Additive Manufacturing – 3D Printing Industry: Offers detailed explanations of different 3D printing processes and technologies.

- 3D Printing – Wikipedia: Comprehensive information on the history, processes, and applications of 3D printing.

3D printing is a transformative technology that enables the creation of complex, custom, and highly detailed objects with a wide range of materials and applications.

Related Conten: Custom Plastic Fabrication