HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate) are two of the most widely used plastics in packaging and consumer products. Both materials have distinct properties, making them suitable for specific applications. Understanding the differences between HDPE and PET can help industries and consumers make informed choices based on functionality, sustainability, and cost.

1. What is HDPE?

HDPE (High-Density Polyethylene) is a thermoplastic polymer made from petroleum. It is characterized by its strength, durability, and chemical resistance. HDPE has a higher density compared to other types of polyethylene, giving it superior strength-to-density ratios.

Key Properties of HDPE:

- Durability: Resistant to impact and wear.

- Chemical Resistance: Withstands most acids and bases.

- Lightweight: Despite its strength, it is lightweight and easy to handle.

- Recyclability: Commonly recycled and assigned the recycling number 2.

2. What is PET?

PET (Polyethylene Terephthalate) is a polyester-based thermoplastic that is lightweight, transparent, and highly durable. It is widely used in packaging, especially for food and beverages, due to its clarity and barrier properties.

Key Properties of PET:

- Clarity: Provides excellent transparency for product visibility.

- Barrier Properties: Resistant to gas and moisture, making it ideal for food storage.

- Lightweight and Strong: Combines low weight with high tensile strength.

- Recyclability: Frequently recycled and assigned the recycling number 1.

3. HDPE vs. PET: Key Differences

| Feature | HDPE | PET |

| Density | Higher density than PET; rigid and tough. | Lower density; lightweight and flexible. |

| Transparency | Opaque or translucent. | Transparent, suitable for clear packaging. |

| Chemical Resistance | Excellent chemical resistance. | Moderate resistance; less suitable for harsh chemicals. |

| Temperature Tolerance | Withstands temperatures up to 120°C. | Performs well between -40°C and 70°C. |

| Recyclability | Widely recycled into pipes, crates, etc. | Widely recycled into fabrics, bottles, etc. |

| Applications | Milk jugs, detergent bottles, pipes. | Beverage bottles, food containers, films. |

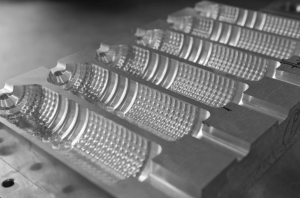

4. Applications of HDPE Plastic

HDPE is a versatile material with applications in both consumer and industrial sectors:

- Packaging: Milk jugs, detergent bottles, and juice containers.

- Construction: Pipes, plastic lumber, and geomembranes.

- Consumer Goods: Toys, outdoor furniture, and storage bins.

- Industrial Use: Chemical containers and fuel tanks.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

5. Applications of PET Plastic

PET is widely used in industries requiring clarity and food-grade material:

- Beverage Containers: Water bottles, soda bottles, and juice containers.

- Food Packaging: Trays, containers, and jars.

- Textiles: Used in polyester fibers for clothing and fabrics.

- Medical Applications: Sterile containers for pharmaceuticals.

6. Advantages of HDPE Plastic

- Durability: Resistant to cracking and impact, making it ideal for heavy-duty uses.

- Chemical Resistance: Can hold harsh chemicals without degradation.

- UV Resistance: Performs well in outdoor applications due to its UV resistance.

- Cost-Effective: Offers long-term durability, reducing replacement costs.

7. Advantages of PET Plastic

- Transparency: Allows consumers to see the product inside, making it ideal for food and beverage packaging.

- Barrier Properties: Protects against oxygen and moisture, extending shelf life.

- Lightweight: Reduces transportation costs due to its low weight.

- Recyclability: Can be recycled into various products, including clothing and new containers.

8. HDPE vs. PET: Environmental Impact

Recyclability

- HDPE: Highly recyclable; often repurposed into construction materials, piping, and industrial containers.

- PET: Equally recyclable; commonly turned into fibers for textiles or new bottles.

Sustainability

- HDPE: Has a lower carbon footprint during production but may not be as widely recycled into new food-grade products.

- PET: Frequently recycled into food-grade materials, reducing the need for virgin plastics.

Decomposition

Both materials are non-biodegradable and require proper recycling systems to reduce environmental harm.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

9. Cost Comparison: HDPE vs. PET

- HDPE: Generally less expensive to produce and is preferred for bulk packaging and industrial uses.

- PET: Slightly more expensive due to its clarity and food-safe properties but offers superior marketability for consumer goods.

10. Which Plastic Should You Choose?

The choice between HDPE and PET depends on the specific requirements of your project:

- Choose HDPE if you need a strong, chemical-resistant material for industrial applications or opaque packaging.

- Choose PET for lightweight, transparent packaging that offers excellent barrier properties for food and beverages.

11. Conclusion

Both HDPE and PET plastics are essential materials in modern packaging and manufacturing. HDPE offers superior durability and chemical resistance, making it ideal for industrial and heavy-duty applications. PET, with its clarity and lightweight design, is perfect for consumer-focused products like food and beverage packaging. Understanding the strengths and limitations of each material ensures the right choice for your specific needs.

12. FAQs

Q1: Can HDPE and PET be recycled together?

A: No, they must be separated during recycling due to differences in their melting points and chemical properties.

Q2: Which plastic is more environmentally friendly?

A: PET is often considered more eco-friendly because it can be recycled into food-grade materials, whereas HDPE recycling is more limited.

Q3: Is HDPE food-safe?

A: Yes, HDPE is food-safe and commonly used for milk jugs and juice containers.

Q4: Can PET be used for hot liquids?

A: PET is not suitable for high temperatures as it may warp or leach chemicals.

Q5: Which is stronger, HDPE or PET?

A: HDPE is stronger and more impact-resistant, while PET offers better clarity and flexibility.