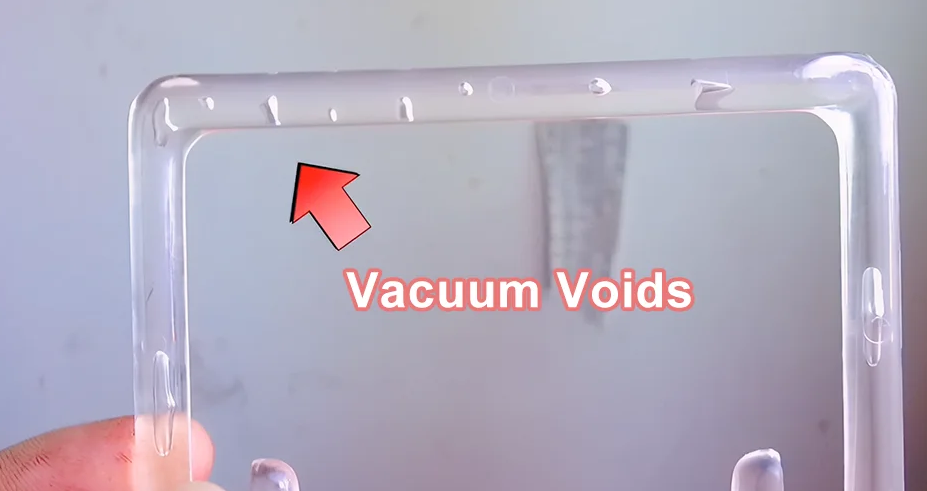

Bubbles in injection molded parts are a common defect that can compromise the appearance and structural integrity of the final…

Blogs

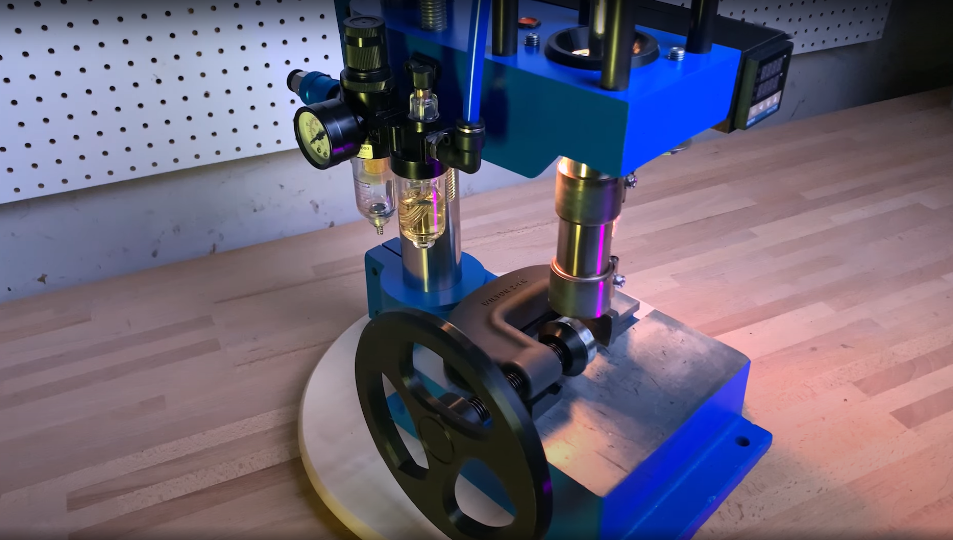

Do-it-yourself (DIY) injection molding can be a cost-effective way to produce small batches of plastic parts without investing in expensive…

The cost-effectiveness of injection molding depends on several factors, including production volume, part complexity, material choice, and tooling costs. Here’s…

The cost of injection molding can vary significantly based on several factors, including the complexity of the part, the type…

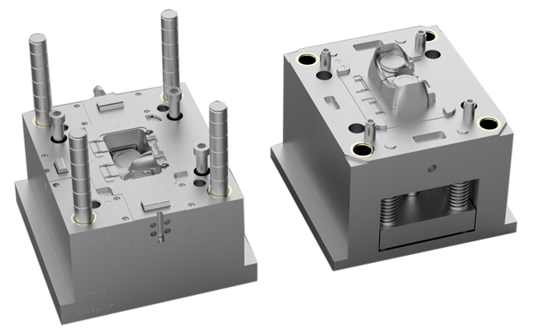

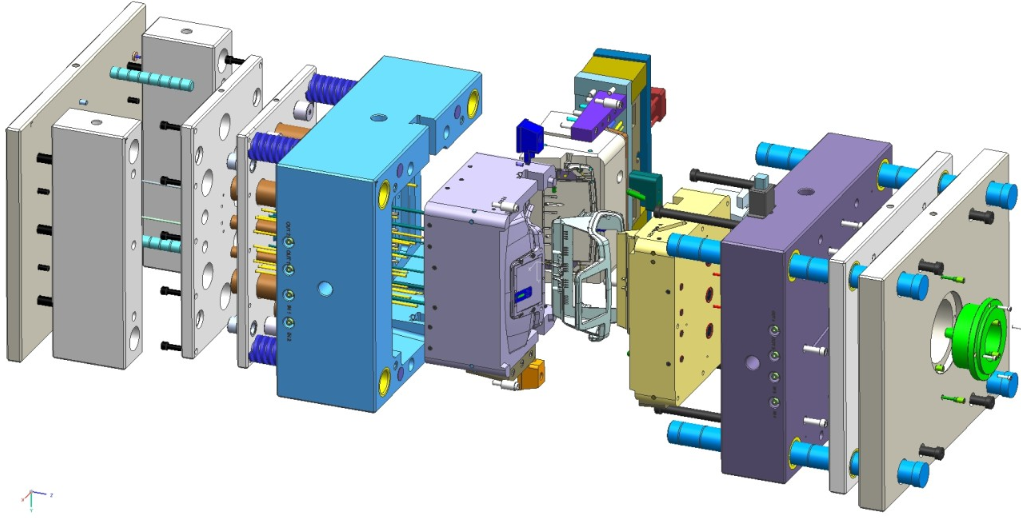

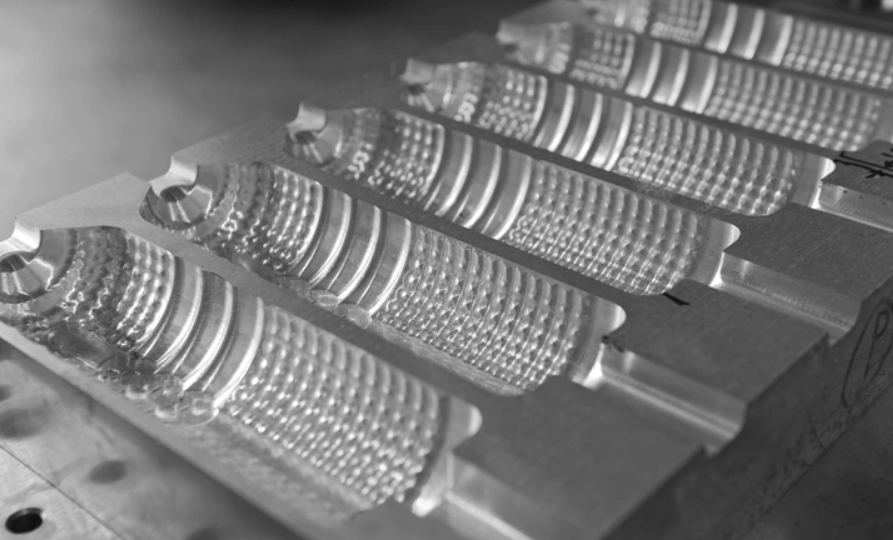

Designing a mold for plastic injection molding involves several critical steps to ensure the final part meets specifications and is…

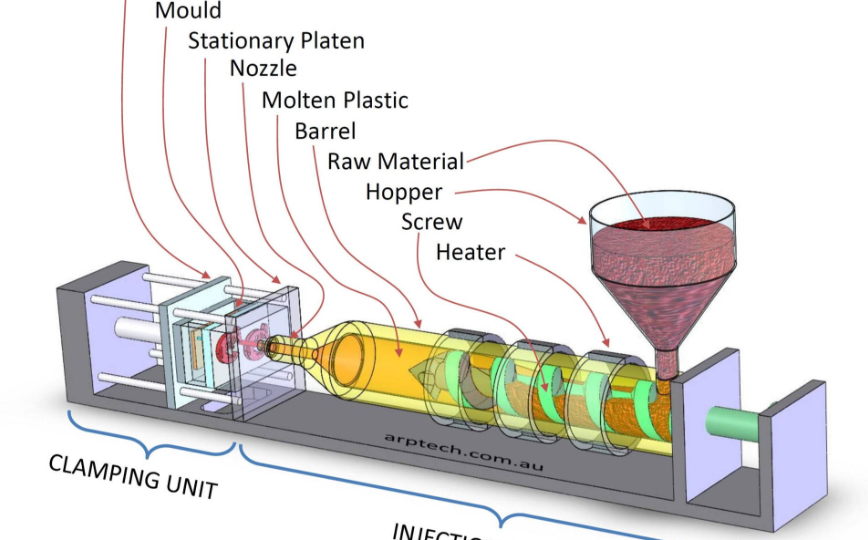

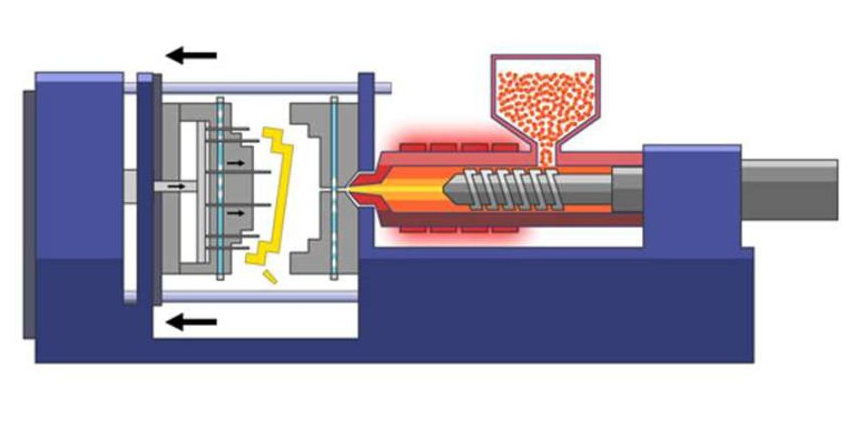

Plastic injection molding is a widely used manufacturing process for producing parts by injecting molten plastic material into a mold….

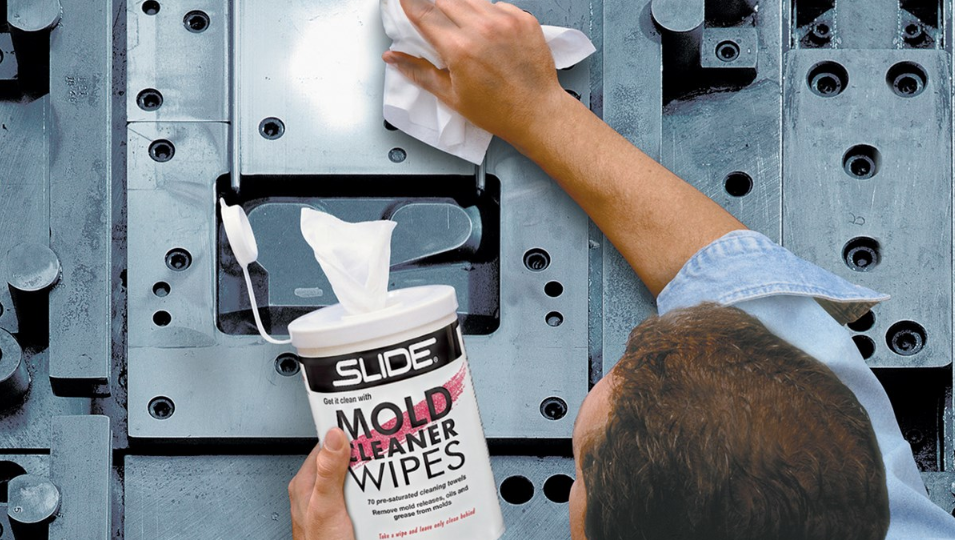

Cleaning injection molds is a critical maintenance task to ensure high-quality production, extend the life of the molds, and prevent…

Weld lines, also known as knit lines or meld lines, are visible lines on a molded part where two or…

Aluminum itself cannot be injection molded in the traditional sense used for thermoplastics. Injection molding typically involves melting a material…

Yes, acrylic, also known as polymethyl methacrylate (PMMA), can be injection molded. It’s a popular thermoplastic material with excellent optical…