Yes, silicone can be injection molded, a process commonly referred to as liquid silicone rubber (LSR) injection molding. This method is widely used for producing high-precision, complex parts with excellent material properties. Here’s an in-depth look at silicone injection molding:

Properties of Silicone for Injection Molding

- Flexibility and Elasticity:

- Silicone exhibits high flexibility and elasticity, making it suitable for parts that require frequent bending and stretching.

- Temperature Resistance:

- Silicone can withstand a wide range of temperatures, from -50°C to 250°C (-58°F to 482°F), without losing its properties.

- Chemical Resistance:

- It is resistant to many chemicals, including oils, solvents, and acids.

- Biocompatibility:

- Silicone is biocompatible, making it suitable for medical and food-grade applications.

- Durability:

- It has excellent durability and can withstand repeated stress and strain.

- Electrical Insulation:

- Silicone is an excellent electrical insulator.

Applications of Silicone Injection Molding

- Medical:

- Seals, gaskets, syringes, catheters, and medical device components.

- Automotive:

- Seals, gaskets, and protective covers.

- Consumer Goods:

- Keypads, kitchenware, baby products, and wearables.

- Electronics:

- Seals, gaskets, and protective cases for electronic devices.

- Industrial:

- Seals, gaskets, and hoses.

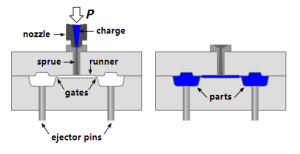

Silicone Injection Molding Process

- Material Preparation:

- LSR is supplied in two-part kits that need to be mixed just before molding. The mixture typically includes a base and a curing agent.

- Injection Molding Machine Setup:

- Temperature Settings: Barrel temperatures are typically set between 20°C to 80°C (68°F to 176°F) to prevent premature curing.

- Injection Pressure: High injection pressures are used to ensure complete filling of the mold cavity.

- Mold Temperature: Molds are often heated to around 170°C to 200°C (338°F to 392°F) to aid in the curing process of the silicone.

- Molding Cycle:

- Mixing: The two-part LSR is mixed and fed into the injection molding machine.

- Injection: The mixed silicone is injected into the heated mold cavity under high pressure.

- Curing: The silicone cures (vulcanizes) in the mold. Curing time depends on the part geometry and mold temperature.

- Cooling: After curing, the part is cooled sufficiently to be handled.

- Ejection: The finished part is ejected from the mold.

- Post-Processing:

- Parts may require trimming to remove flash or excess material.

- Additional finishing processes, such as surface treatment or coating, may be applied to enhance appearance and properties.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Benefits of Silicone Injection Molding

- Precision: Capable of producing high-precision components with tight tolerances.

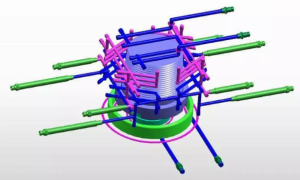

- Complex Geometries: Suitable for molding complex shapes and intricate designs.

- Efficiency: High production rates make it cost-effective for large-volume production.

- Consistency: Produces consistent and repeatable parts with minimal variation.

- Biocompatibility: Suitable for medical and food-grade applications.

Considerations

- Material Handling:

- Proper handling and mixing of the two-part LSR are crucial to ensure consistent curing and part quality.

- Mold Design:

- Proper mold design, including adequate cooling and venting systems, is essential to ensure part quality and efficient production.

- Curing Time:

- Adequate curing time is necessary to achieve the desired mechanical and chemical properties of the silicone.

- Temperature Control:

- Precise temperature control is crucial to avoid premature curing and ensure high-quality parts.

Conclusion

Silicone injection molding is a versatile and efficient process for producing high-precision, complex parts with excellent material properties. It is widely used in various industries, including medical, automotive, consumer goods, electronics, and industrial applications. Proper material preparation, machine setup, and mold design are critical to achieving high-quality silicone injection-molded parts. By carefully managing these factors, manufacturers can leverage the benefits of silicone injection molding to produce durable, high-performance components for a wide range of applications.

Related Conten: Custom Molders Corp