Nylon and PVC (polyvinyl chloride) have significantly different material properties and processing requirements, making it challenging to use the same injection molding setup for both materials without modifications. Here’s an overview of why this is the case and what considerations are necessary if attempting to mold both materials using the same equipment:

Material Properties and Processing Requirements

1. Nylon (Polyamide)

- Processing Temperature: Nylon typically requires a high processing temperature, usually between 230°C and 280°C (446°F to 536°F).

- Moisture Sensitivity: Nylon is hygroscopic and must be dried before molding to avoid defects like splay or bubbles.

- Mold Temperature: The mold temperature for nylon is usually in the range of 80°C to 100°C (176°F to 212°F) to ensure good part quality and dimensional stability.

2. PVC (Polyvinyl Chloride)

- Processing Temperature: PVC has a lower processing temperature, typically between 160°C and 210°C (320°F to 410°F). Exceeding these temperatures can cause PVC to decompose and release harmful gases.

- Shear Sensitivity: PVC is sensitive to shear and requires careful control of injection speed and pressure to prevent degradation.

- Mold Temperature: The mold temperature for PVC is usually much lower, around 20°C to 50°C (68°F to 122°F), to ensure good part quality and to prevent the material from sticking to the mold.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

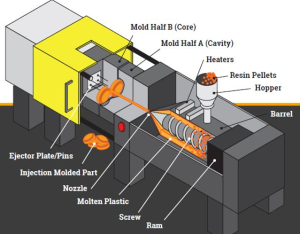

Challenges of Using the Same Injection Molding Machine

1. Temperature Control

- Barrel and Mold Temperatures: The significant difference in processing temperatures means that the injection molding machine must be capable of adjusting to a wide range of temperatures. Switching between the high temperatures needed for nylon and the lower temperatures required for PVC can be challenging and may necessitate significant downtime for heating or cooling adjustments.

2. Material Contamination

- Material Residue: Residual nylon in the injection molding machine can contaminate PVC, leading to quality issues and possible degradation. Thorough cleaning of the barrel and screw is necessary when switching materials to prevent cross-contamination.

3. Decomposition Risk

- PVC Degradation: If the machine is not adequately cleaned after processing nylon, the higher residual heat can cause PVC to decompose, releasing hydrochloric acid gas, which is corrosive and hazardous.

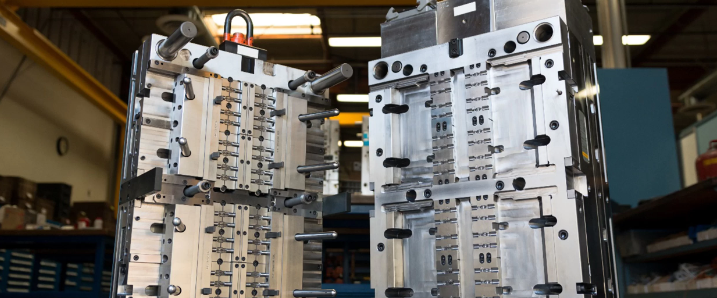

4. Mold and Tooling Considerations

- Mold Design: Different mold designs may be required to accommodate the different cooling rates and shrinkage behaviors of nylon and PVC. Molds designed for nylon may not provide optimal results for PVC parts and vice versa.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Practical Considerations

1. Separate Machines

- Dedicated Machines: Ideally, separate injection molding machines should be used for nylon and PVC to avoid the challenges of temperature control and contamination.

2. Thorough Cleaning

- Proper Cleaning Protocols: If using the same machine, establish thorough cleaning protocols to ensure all residual material is removed before switching materials. This may include purging the machine with a suitable purging compound.

3. Adjustable Settings

- Versatile Machines: Use injection molding machines with versatile and precise control systems that can handle the broad range of processing conditions required by both materials.

References

- Injection Molding Processing Conditions of Thermoplastics Materials: Provides detailed information on the processing conditions for various thermoplastics, including nylon and PVC. Injection Molding Processing Conditions

- Plastics Technology: Discusses the challenges and considerations in injection molding various thermoplastics. Plastics Technology

In summary, while it is technically possible to use the same injection molding machine for nylon and PVC, it requires careful management of temperature controls, thorough cleaning to avoid contamination, and potentially different mold designs. For optimal results and efficiency, dedicated machines are recommended.

Related Conten: Prototype Injection Molding