When it comes to 3D printing, several types of software are typically used throughout the process, from design to slicing to printer control. Here’s a breakdown of the key categories of software you might need and some of the most popular options for each:

1. 3D Modeling Software

3D modeling software is used to create and edit the 3D models that you will print. Here are some popular options:

- Tinkercad: A user-friendly, web-based application ideal for beginners.

- Fusion 360: A powerful, cloud-based CAD tool from Autodesk suitable for both beginners and professionals.

- Blender: An open-source 3D modeling and animation software that’s very versatile but has a steeper learning curve.

- SketchUp: Easy-to-use modeling software that’s popular for architectural designs.

- SolidWorks: A professional-grade CAD software used extensively in engineering and product design.

- FreeCAD: An open-source parametric 3D CAD modeler useful for a variety of engineering and design applications.

2. Slicing Software

Slicing software takes your 3D model and converts it into instructions that the 3D printer can follow (G-code). Here are some widely-used slicing programs:

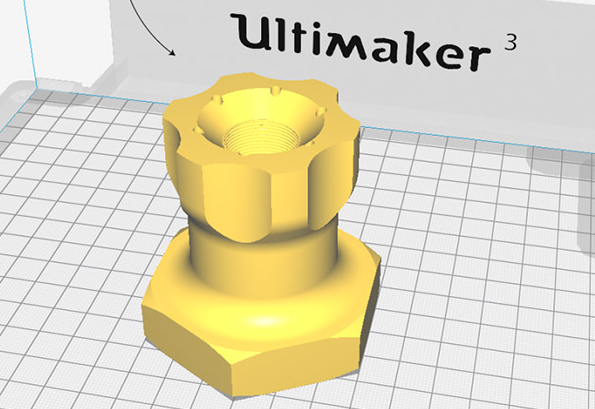

- Cura: Developed by Ultimaker, it’s one of the most popular free slicing software with extensive features and an active community.

- PrusaSlicer: Based on Slic3r, this software is developed by Prusa Research and optimized for Prusa printers but works with many other printers as well.

- Simplify3D: A commercial slicing software known for its robust features and control over print settings, though it comes with a price.

- MatterControl: An all-in-one solution for designing, slicing, and controlling your 3D printer.

- ChiTuBox: Popular among resin printer users, offering a range of features specifically for SLA/DLP printers.

- KISSlicer: Offers powerful slicing capabilities, especially useful for advanced users.

3. Printer Control Software

Printer control software allows you to manage and monitor your 3D printer. This can include sending the G-code to the printer, adjusting settings, and monitoring print progress. Some popular options include:

- OctoPrint: A widely-used open-source 3D printer management tool that runs on a Raspberry Pi and provides remote monitoring and control.

- Repetier-Host: Offers a comprehensive set of tools for controlling your 3D printer, slicing models, and managing multiple printers.

- MatterControl: Besides slicing, it also offers robust printer management features.

- AstroPrint: A cloud-based platform for managing and monitoring 3D prints remotely.

[elementor-template id=”4330″]

4. Post-Processing Software

Post-processing software helps you repair and prepare 3D models, especially if they have issues that need fixing before printing.

- Meshmixer: From Autodesk, Meshmixer provides powerful tools for manipulating and repairing 3D models.

- Netfabb: Also from Autodesk, Netfabb is a professional software tool used for preparing 3D models for manufacturing.

- 3D Builder: A free tool from Microsoft for Windows that offers basic 3D modeling and repair features.

Conclusion

The best software for 3D printing depends on your specific needs, experience level, and the type of projects you are working on. For beginners, Tinkercad and Cura are excellent starting points. More advanced users might prefer Fusion 360 for modeling and Simplify3D or PrusaSlicer for slicing. OctoPrint is a fantastic option for anyone looking to manage their printer remotely. By selecting the right tools for each stage of the 3D printing process, you can streamline your workflow and achieve better results.

Related Conten: Injection Molding China

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|