Are you constantly trying to balance quality with budget when ordering custom plastic tokens or custom challenge coins? You’re not alone. Many procurement managers and business owners face the same challenge. The good news is that with the right strategies, you can achieve significant savings—potentially up to 40%—without compromising on quality. In this detailed guide, we’ll walk you through seven practical, proven methods to optimize your spending on custom plastic tokens bulk orders. We’ll also share a real-world success story from one of our European clients. Let’s dive in and start saving!

1. Understanding the Hidden Factors in Bulk Pricing

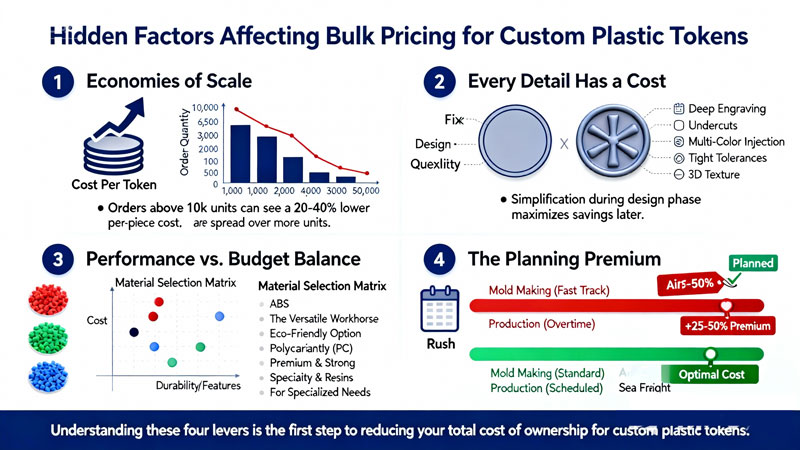

When you ask “how much do custom challenge coins cost?” or look for custom plastic coins no minimum orders, the initial quote is just the tip of the iceberg. True cost optimization starts with understanding what drives the price. From our experience, the main levers are:

- Order Quantity (Economies of Scale): This is the most significant factor. A run of 10,000 tokens has a vastly lower per-unit cost than 500 tokens, as the fixed costs (like mold creation) are amortized. It’s almost always more cost-effective to plan for a slightly larger, consolidated order than multiple small ones.

- Design Complexity: Every undercut, sharp edge, deep engraving, or multi-color injection adds time and cost to both mold making and production. Simplifying a design can lead to substantial savings.

- Material Choice: While ABS is an industry-standard and cost-effective workhorse, specifying a specialty plastic without need can inflate costs. We’ll explore this balance in section 3.

- Turnaround Time: Requiring a “rush” production schedule often incurs premium charges. Planning ahead for standard lead times is one of the easiest ways to save.

2. Master Mold Design for Long-Term Savings

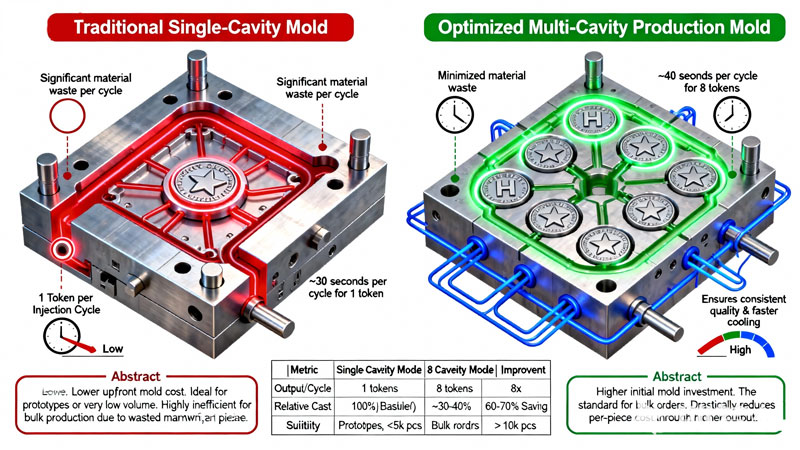

The mold is the heart of injection molding, and its design critically impacts your custom challenge coins cost. An optimized mold isn’t just about the initial price; it’s about durability, production speed, and yield rate over its entire lifetime.

- Optimize for Multi-Cavity Production: A well-designed mold can have multiple cavities (e.g., 4, 8, 16) to produce several tokens per injection cycle. This dramatically increases output and reduces machine time per piece. Our mold design experts excel at creating efficient multi-cavity molds that maximize your bulk plastic coins production.

- Standardize Components: Using standard-sized mold bases, ejector pins, and cooling channels from our inventory, compared with fully custom components, can reduce mold cost and lead time by 15-25%.

- Design for Mold Longevity: We use hardened steel for high-wear areas in molds destined for bulk custom coins production. This initial investment prevents costly downtime and mold repairs later, protecting your supply chain. Industry practice indicates that a robust mold can last for over a million cycles with proper maintenance.

3. Strategic Material Selection: Balancing Performance & Budget

Choosing the right plastic is a critical decision. It’s not just about finding the cheapest option, but the most cost-effective one for your application.

- ABS (Acrylonitrile Butadiene Styrene): Our most widely used material for custom plastic coins. It’s durable, offers excellent surface finish for printing/engraving, and is highly versatile. For most promotional, membership, or gaming tokens, ABS provides the perfect balance.

- Polypropylene (PP): More flexible and has good chemical resistance. Can be a good option if a slight flex is desired, but it’s often comparable in price to ABS.

- Recycled Content Plastics: For clients with sustainability goals, we offer grades with recycled content. Notably, these can sometimes offer a cost saving while meeting your ESG criteria.

- Pro Tip: Avoid over-specifying. Does your indoor casino token really need UV-stabilized, high-heat resistant plastic? Probably not. Our engineers can guide you to the most suitable material on our materials page, ensuring you don’t pay for properties you don’t need.

4. The Power of Standardization

This is a powerful yet often overlooked strategy. While custom challenge coins are by definition unique, standardizing certain elements can unlock huge savings.

- Standard Size & Shape: If possible, design your token to fit a standard diameter and thickness (e.g., 1.75″ diameter, 3mm thick). This allows us to use existing, proven mold frames and standardized cutting tools.

- Standard Color Base: Instead of custom-matching a specific Pantone color for the base plastic (which requires a separate, cleaned machine run), choose from our stock color palette. Apply your unique branding through highly detailed pad printing or laser engraving on a standard colored token.

- Standard Packaging: We can provide plastic coin wrappers or standard plastic bags in bulk, which is far more economical than fully custom printed boxes for every order.

5. Building a Partnership: Long-Term Collaboration Discounts

At DTG TECH, we value long-term relationships. We proactively offer better pricing to clients who view us as a strategic manufacturing partner rather than just a one-time vendor.

- Annual Volume Agreements: Commit to an estimated annual volume (e.g., 200,000 tokens) across multiple orders, and you’ll secure a preferential rate for the entire year.

- Repeat Order Discounts: Using the same mold for a reorder eliminates mold cost entirely. We offer automatic discounts on repeat production runs, making your custom challenge coins cheap over their lifecycle.

- Project Pipeline Planning: By sharing your forward product pipeline with our project managers, we can schedule production during our less busy periods, sometimes passing on the efficiency savings to you.

6. Smart Logistics & Supply Chain Management

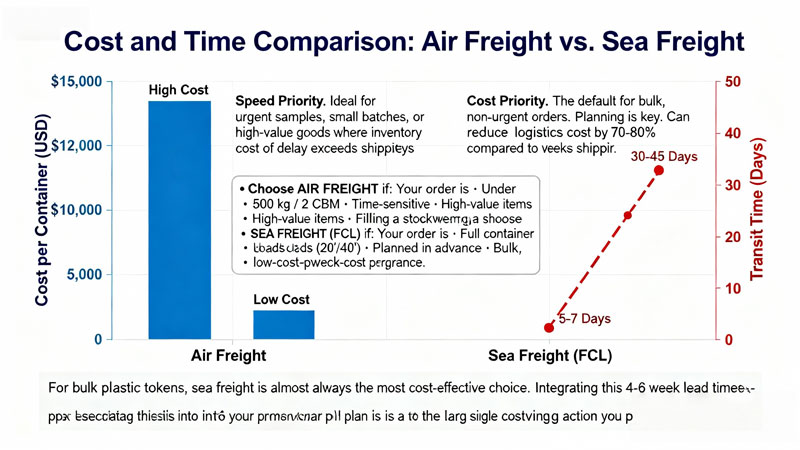

Shipping costs for plastic coins bulk orders can be significant. Intelligent planning here can save thousands.

- Consolidate Shipments: Combine multiple product runs (e.g., tokens and bulk custom plastic cups) into a single container shipment. The cost per unit plummets.

- Plan for Sea Freight: For non-urgent, large bulk custom coins orders, sea freight is typically 70-80% cheaper than air freight. Building this longer lead time (4-6 weeks) into your plan is a key cost-saving tactic.

- Use Our Logistics Network: We have established partnerships with major freight forwarders. We can often secure better rates than a client sourcing shipping independently and handle all documentation, making the process seamless for you.

7. Real-World Case Study: A UK-Based Loyalty Program Provider

Client: A prominent loyalty and rewards program company based in London, UK.

Challenge: They needed high-quality, NFC-enabled custom plastic tokens for a premium hotel chain’s membership program. Their previous supplier had inconsistent quality, long lead times (12+ weeks), and rising costs, which eroded their project margins.

Our Solution & Partnership: DTG TECH engaged in a deep consultation. We analyzed their design and proposed three key changes: 1) Slightly modifying the token edge to allow for an 8-cavity mold (vs. their old 4-cavity), 2) Switching from a custom-mixed blue to a stock ABS blue with superior pad printing for the logo, and 3) Planning production to align with sea freight schedules.

The Result: The first order was for 50,000 tokens. Ultimately, we achieved a 35% reduction in per-unit cost compared to their previous quote. The quality was consistently high, with zero defects reported. Most importantly, the integrated project management and weekly English progress reports gave them peace of mind. The delivery cycle was shortened to 9 weeks door-to-door in the UK. The client’s Procurement Director stated: “DTG TECH didn’t just provide a product; they provided a cost-saving strategy. The quality is superior, and the partnership has given us a predictable, reliable supply chain.” You can find more such testimonials on our case studies page.

Frequently Asked Questions (FAQs)

Q1: What is the typical minimum order quantity (MOQ) for custom plastic tokens?

A: While we are flexible, a practical MOQ for a cost-effective project that includes a custom mold is typically around 1,000 to 2,000 pieces. For simpler designs using stock mold bases, we can sometimes accommodate custom plastic coins no minimum requests for as low as 500 pieces. It’s always best to consult with us directly for an accurate quote based on your specific design.

Q2: How much does it cost to make custom challenge coins?

A: The custom challenge coins cost varies widely based on the seven factors discussed above. As a rough benchmark, simple, single-color plastic custom coins in bulk (10,000+ units) can start from a few cents per piece. More complex, multi-material, or small-quantity orders will have a higher per-unit cost. We provide transparent, detailed quotes breaking down mold and per-unit costs so you see exactly what you’re paying for.

Q3: Do you provide design services if I only have an idea or a logo?

A: Absolutely! Our mold design and engineering team is an integral part of our service. We can take your concept, sketch, or logo and develop it into a production-ready 3D design that is optimized for manufacturability and cost. This service often pays for itself by avoiding costly design flaws before tooling begins.

Conclusion & Your Next Step to Saving 40%

Reducing your spend on custom plastic tokens and challenge coins is not about finding the cheapest supplier; it’s about partnering with a smart manufacturer who can engineer cost out of the process. At DTG TECH, we combine industry-standard ISO-certified quality with strategic cost-optimization expertise. We believe that a transparent, collaborative approach is the key to unlocking maximum value for your procurement budget.

Ready to see how much you can save? Don’t just look for a custom challenge coins coupon code online—get a real, tailored strategy.

- Send us your design or idea for a free, no-obligation review and cost analysis.

- Ask us about our “Cost Optimization Audit” for existing token designs.

- Speak directly with our project managers in English to discuss your specific needs and volume.

Contact DTG TECH today for a detailed quote and let us show you how to get premium custom plastic tokens bulk at a significantly reduced total cost. Your journey to saving up to 40% starts with one conversation.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|