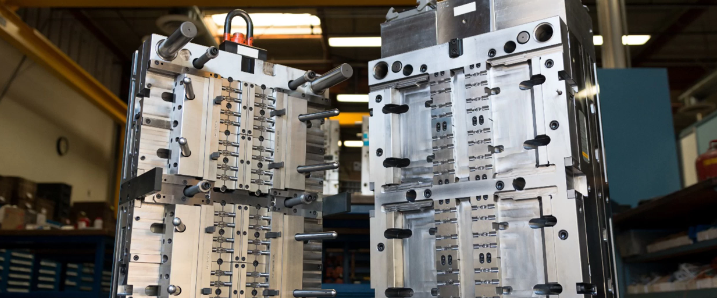

Yes, one plastic injection molding machine can be used with various molds to produce different parts, making it a versatile tool in manufacturing. However, there are several factors and considerations to ensure successful mold interchangeability:

Factors and Considerations

1. Machine Compatibility

- Clamp Force: The machine’s clamp force must be sufficient for the molds being used. Different molds may require different clamp forces to maintain proper sealing during injection.

- Shot Size: The injection unit must have the appropriate shot size to accommodate the volume of material needed for each mold.

2. Mold Size and Mounting

- Mold Dimensions: The physical size of the molds must fit within the machine’s platens and tie-bar spacing.

- Mounting Systems: Standardized mounting systems, such as the SPI (Society of the Plastics Industry) standards, can facilitate the quick interchange of molds.

[elementor-template id=”4330″]

3. Temperature and Material Compatibility

- Heating/Cooling Requirements: Different molds may require specific temperature settings for the mold and the material being processed. The machine must be capable of adjusting and maintaining these temperatures.

- Material Handling: The machine should be able to handle the range of materials that will be used with the various molds, including differences in melt temperature and viscosity.

4. Control Systems

- Programmable Settings: Modern injection molding machines have programmable control systems that allow for the quick adjustment of processing parameters to match the requirements of different molds and materials.

- Automation and Robotics: Automated systems, such as robotic arms, can be programmed to work with various molds, improving efficiency and reducing changeover time.

Practical Steps for Using Various Molds

1. Standardization

- Use Standardized Mold Bases: Standardizing mold bases can significantly reduce the time and effort required to switch molds, as only the core and cavity inserts need to be changed.

- Quick-Change Systems: Implementing quick-change mold systems can streamline the process, allowing for rapid switching with minimal downtime.

2. Maintenance and Preparation

- Regular Maintenance: Regular maintenance of both the machine and molds ensures compatibility and prevents issues during mold changes.

- Proper Preparation: Ensuring molds are prepped and ready before switching, including preheating if necessary, can reduce downtime and improve efficiency.

3. Training and Procedures

- Operator Training: Ensuring that operators are trained in the procedures for changing molds and adjusting machine settings is crucial for smooth transitions.

- Standard Operating Procedures (SOPs): Establishing SOPs for mold changes can help standardize the process and minimize errors.

[elementor-template id=”4331″]

References

- Plastics Technology: Discusses the flexibility and considerations for using different molds on injection molding machines.

- Injection Molding Handbook: Provides detailed information on machine compatibility, mold design, and operational procedures.

- Advanced Technology and Materials: Covers modern technologies and systems that facilitate the use of multiple molds on a single machine.

By addressing these considerations and following best practices, a single plastic injection molding machine can efficiently use various molds, making it a flexible and valuable asset in manufacturing operations

Related Conten: Plastic Injection Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|