Leading Acrylic Wine Barware Manufacturer providing durable, stylish, and fully customizable bar solutions for global bars, restaurants, hotels, beverage brands, and wholesalers.

Your Trusted Acrylic Wine Barware Manufacturer

As a professional Acrylic Wine Barware Manufacturer, we specialize in producing durable, stylish, and impact-resistant barware tailored for commercial environments such as bars, nightclubs, restaurants, hotels, and beverage brand promotions. Our solutions integrate high-clarity plastics, premium mold design, precision injection molding, and advanced surface decoration techniques.

Whether you are looking for acrylic measuring cups, mixing pitchers, cocktail cups, colored drinkware, or fully customized bar tools, we offer OEM & ODM services that align with your branding requirements.

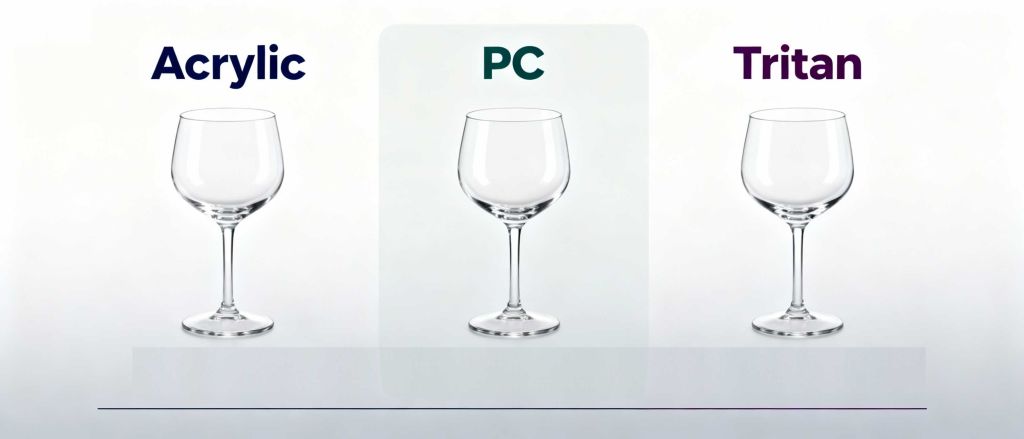

Choosing the Right Material for Your Barware

Barware performance depends strongly on the chosen material. We offer Acrylic (PMMA), Polycarbonate (PC), and Tritan (Copolyester) solutions tailored to your usage environment and budget.

Material Comparison Table

| Comparison Item | Acrylic (PMMA) | Polycarbonate (PC) | Tritan |

|---|---|---|---|

| Clarity | ★★★★★ | ★★★★☆ | ★★★★★ |

| Impact Resistance | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Scratch Resistance | ★★★☆☆ | ★★☆☆☆ | ★★★★☆ |

| Typical Uses | Outdoor & Events | Bars & Restaurants | Premium Brands |

Our Manufacturing Process

We support every stage of your OEM/ODM project with precision engineering.

1. Mold Design

Every high-quality acrylic barware product begins with expert mold design. Our engineering team develops detailed CAD models optimized for clarity, structure, cooling, and cycle efficiency.

2. Prototype Manufacturing

Before mass production, we create physical prototypes—allowing you to verify weight, design, capacity, and ergonomics.

3. 3D Printing

For rapid validation, we offer high-resolution 3D-printed models to preview shape, form, and branding layout.

4. Mold Manufacturing

Using CNC, EDM, and precision polishing, we build durable molds suitable for acrylic, PC, or Tritan production.

5. Plastic Injection Molding

Our injection molding machines (80T–800T) produce crystal-clear, impact-resistant barware with minimal defects and perfect wall thickness.

6. Surface Decoration

We support multiple professional decoration techniques:

- Pad printing

- UV printing

- Laser engraving

- Metallic spray

- Hot stamping

- PVD metallization

Why Choose Our Factory?

Advanced Facility

Our manufacturing facility includes: CNC machining centers, EDM machines, 80T–800T injection molding machines, EOS & HP MJF 3D printing, and advanced polishing equipment.

ISO 9001:2015 Certified

Strict production control ensures consistent quality for global hotel chains, restaurants, and wholesalers.

Where Our Acrylic Barware Is Used

- Bars & Clubs

- Restaurants & Hotels

- Beverage Brand Promotions

- Poolside & Outdoor Events

- Catering Companies

- Nightlife & Luxury Lounges

OEM & ODM Customization

We customize barware according to your brand needs:

- Custom shapes & sizes

- Pantone colors

- Custom logo printing

- Metallic rims (gold/silver/rose gold)

- Gift packaging

- Brand identity decoration for beverage companies

Market Outlook & Emerging Trends

With outdoor lifestyles, reusable drinkware demand, and sustainability trends rising, the market for acrylic and Tritan barware continues to expand. Foodservice, hotel chains, beverage brands, and gift markets increasingly require durable, customizable drinkware.

FAQ

What materials do you offer?

PC, Tritan, PMMA, AS, PS—selected based on durability and market requirements.

Can you produce custom colors?

Yes, any Pantone shade.

Do you support full customization?

Yes. From mold design to decorated finished products.

Lead Time?

35–40 days for new molds; 2–5 days for samples of existing products.

Do you offer free samples?

Yes, you only pay freight.

Start Your Acrylic Barware Project

Contact us for OEM/ODM customization, material consultation, and factory-direct pricing. Get a Quote Now

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|