What are Air Traps in Injection Molding?

Air traps occur in injection molding when air pockets become trapped within the mold cavity during the injection process. These air pockets can be caused by various factors, including the design of the mold, the speed of the injection, and the viscosity of the molten plastic. When the molten plastic fills the mold cavity, any air that is not properly vented can become trapped, creating voids or bubbles within the final molded part.

How Do Air Traps Weaken Injection Molded Parts?

- Structural Weakness: Air pockets within the part can act as stress concentrators, which means they can significantly weaken the structural integrity of the part. Under load or stress, these weak points are more likely to fail, leading to part breakage or deformation.

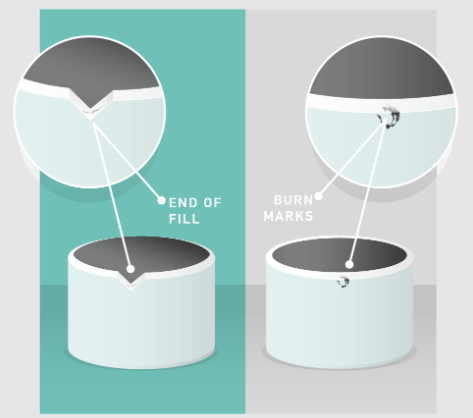

- Surface Defects: Air traps can cause visible surface defects such as blisters, bubbles, or burn marks. These defects not only affect the aesthetic quality of the part but can also compromise its functionality, especially in applications where a smooth surface finish is critical.

- Inconsistent Material Density: The presence of air traps can lead to inconsistent material density within the part. This inconsistency can result in uneven mechanical properties, making the part less reliable and predictable in its performance.

- Reduced Weld Line Strength: Air traps can interfere with the proper formation of weld lines, which are areas where two flow fronts of molten plastic meet and bond. Weak or poorly formed weld lines can significantly reduce the overall strength and durability of the part.

Preventing Air Traps in Injection Molding

- Proper Venting: Ensure that the mold is designed with adequate venting to allow air to escape as the molten plastic fills the cavity. Vents should be placed strategically to prevent air from becoming trapped.

- Optimized Injection Speed: Adjust the injection speed to ensure a smooth and consistent flow of molten plastic into the mold. Too fast or too slow injection can contribute to the formation of air traps.

- Mold Design: Design the mold with gentle transitions and avoid sharp corners or deep recesses where air is more likely to be trapped. Use flow analysis software to simulate the filling process and identify potential problem areas.

- Material Selection: Choose materials with appropriate flow properties for the specific design and application. Some materials are more prone to trapping air than others, so selecting the right material can help mitigate this issue.

- Process Parameters: Fine-tune the injection molding process parameters, including temperature, pressure, and cycle time, to ensure optimal filling and venting.

[elementor-template id=”4330″]

Conclusion

Air traps in injection molding are a common issue that can significantly weaken the final molded parts. By understanding the causes and implementing effective prevention strategies, manufacturers can improve the quality and strength of their injection molded products. Proper mold design, adequate venting, and optimized process parameters are key to minimizing air traps and ensuring the production of high-quality parts.

Related Conten: Injection Molding Factory

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|