For decades, custom plastic tokens have served as reliable workhorses in various industries—from arcades and laundromats to transit systems and promotional events. But what if these simple chips could do more than just represent value or grant access? Enter the era of smart tokens. By embedding Near Field Communication (NFC) or Radio-Frequency Identification (RFID) technology, ordinary tokens are transforming into powerful tools for engagement, data collection, and security. This shift is redefining the potential of personalized plastic tokens, turning them from passive objects into interactive assets. Let’s dive into this technological evolution.

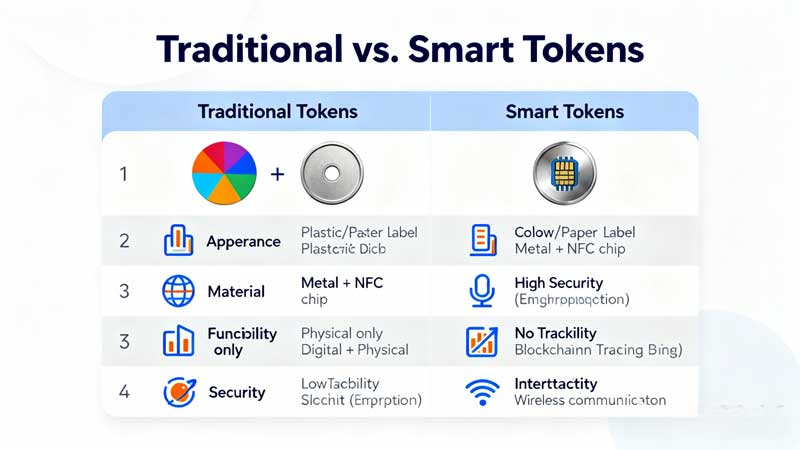

Traditional Tokens vs. Smart Tokens: A Side-by-Side Comparison

The classic plastic token is a masterpiece of simplicity. Injected molded from materials like ABS or acrylic, it’s durable, cost-effective, and perfect for its primary function. However, its intelligence ends with its physical form.

Smart tokens, on the other hand, are where custom plastic token manufacturing meets electronics. They contain a tiny, embedded NFC or RFID chip and antenna, sealed within the plastic during the injection molding process. This integration creates a robust, tamper-resistant product capable of two-way communication with readers.

| Feature | Traditional Token | Smart NFC Token |

|---|---|---|

| Core Function | Physical representation of value/access | Digital data carrier & interactive tool |

| Data Capacity | None | Up to several kilobytes (unique ID, user data, transaction history) |

| Interaction | Visual/Physical handoff | Contactless tap (with a reader or smartphone) |

| Security | Easy to counterfeit | High (encrypted data, unique identifiers) |

| Customer Insight | Zero | Rich data on usage patterns and behavior |

| Long-term Value | Low (single-use) | High (re-writable, multi-purpose) |

Embedding Intelligence: NFC/RFID Technology in Token Manufacturing

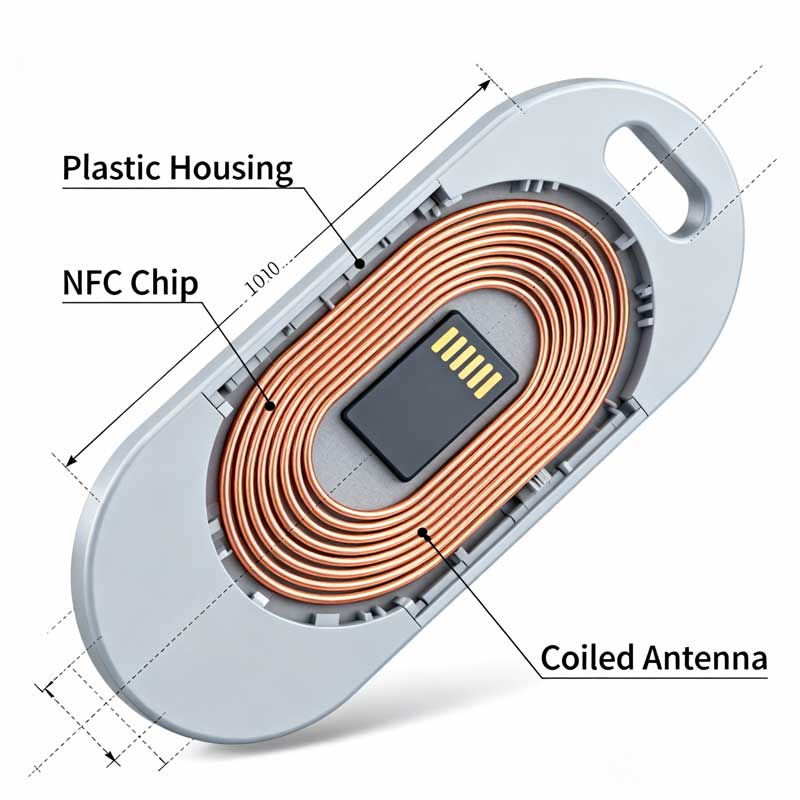

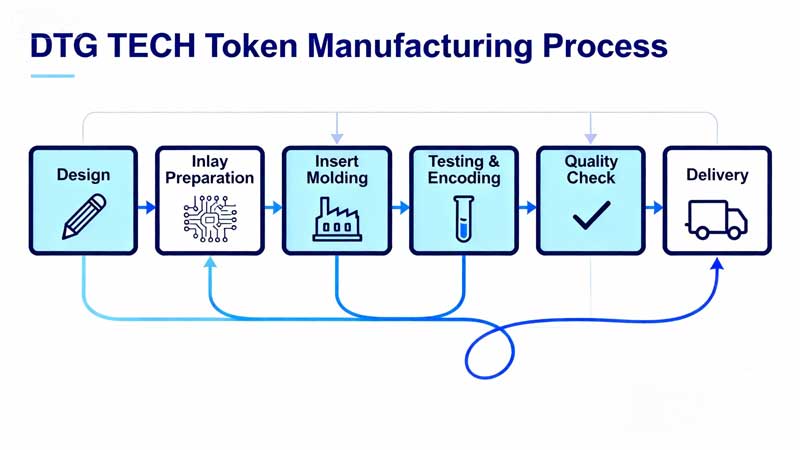

The magic lies in the seamless fusion of plastic and tech. At DTG TECH, manufacturing these advanced personalized plastic tokens requires a precise, two-stage process.

1. Chip & Antenna Inlay Production: First, the microchip is connected to a thin, coiled copper or aluminum antenna, creating an “inlay.” This inlay is the token’s brain.

2. Overmolding/Insert Molding: This is where our expertise in precision plastic injection molding becomes critical. The inlay is carefully placed into the mold cavity. Molten plastic is then injected around it, encapsulating the electronics completely. This protects the chip from moisture, impact, and wear, ensuring the token’s longevity even in harsh environments.

Material Choice is Key: Not all plastics are created equal for this job. We recommend:

- ABS: Excellent toughness and dimensional stability, ideal for high-traffic tokens.

- Polycarbonate (PC): Superior impact resistance and clarity, perfect for premium-looking tokens.

- PVC: Good balance of flexibility and durability, often cost-effective.

Choosing the right material ensures the token not only functions perfectly but also feels premium in hand—a crucial aspect for brand perception. Explore our guide on material selection for more details.

Beyond Access: The Power of Data Tracking & Customer Behavior Analysis

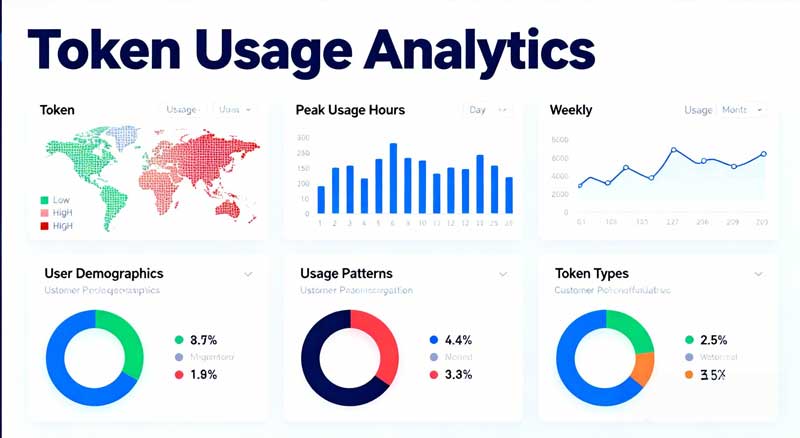

This is where smart tokens become truly revolutionary for businesses. Each tap is a data point.

Imagine a custom plastic token used in a corporate loyalty program. Every time a member uses it to claim a reward, enter an exclusive area, or make a purchase, the system logs:

- Usage Frequency & Timing: When and how often is the token used?

- Location/Point of Interaction: Which specific kiosk, door, or terminal was used?

- Transaction Linking: What action or purchase did the token facilitate?

- User Journey Mapping: How does the token holder move through different touchpoints?

This data allows businesses to move from guessing to knowing. They can analyze customer preferences, optimize facility layouts based on traffic, personalize marketing offers in real-time, and significantly enhance the user experience. A personalized plastic token becomes a direct, data-rich link to your customer.

Case Study: Revolutionizing a Casino Loyalty Program

Challenge: A major casino was using a simple magnetic stripe card for its membership program. The system offered limited data, cards were easily damaged or forgotten, and the “reward” experience felt impersonal and outdated.

Smart Token Solution: DTG TECH partnered with the client to develop a high-end, personalized plastic token embedded with an NFC chip. Each token was uniquely numbered and overmolded with the casino’s logo in premium-feeling Polycarbonate.

Implementation & Results:

- Enhanced Experience: Members received a sturdy, collectible token instead of a flimsy card. Tapping the token on readers felt more engaging than swiping.

- Seamless Integration: The tokens worked with slot machines, entry to VIP lounges, and at payment terminals for food and drinks.

- Data Goldmine: The casino gained unprecedented insight into member behavior: favorite game types, visit duration, spending patterns across amenities.

- Personalized Marketing: Based on token data, the system could offer personalized bonus credits on a member’s preferred slot machine as they tapped in, dramatically increasing redemption rates and satisfaction.

This upgrade transformed their loyalty program from a cost center into a strategic asset for customer retention and revenue growth. View more of our innovative case studies here.

The Future of Smart Tokens: Trends to Watch

The journey has just begun. Here’s what we foresee for the next generation of custom plastic tokens:

1. Sustainability-Driven Materials: Expect a surge in demand for tokens made from recycled plastics or bioplastics. Smart technology will be combined with eco-conscious manufacturing. DTG TECH is actively exploring these sustainable material options.

2. Hybrid Physical-Digital Experiences (Phygital): A token will act as a key to unlock exclusive digital content—AR filters, online loyalty points, or digital collectibles—creating a seamless brand universe.

3. Advanced Personalization & On-Demand Manufacturing: With digital printing and 3D printing for prototyping, even small batches of uniquely designed personalized plastic tokens will become economically viable, perfect for limited-edition corporate events or high-end promotions.

4. Integration with IoT Ecosystems: Smart tokens will communicate not just with dedicated readers, but with a network of smart devices, enabling complex automation in smart offices, hotels, and homes.

Partner with DTG TECH for Your Smart Token Evolution

The transition from traditional to smart tokens is more than a product upgrade—it’s a strategic business decision. It requires a manufacturing partner who understands both the precision of injection molding and the intricacies of electronic integration.

At DTG TECH CO., LTD., we bridge that gap. From initial mold design focused on protecting sensitive electronics to high-volume injection molding with consistent quality, we provide a true one-stop solution. Our process ensures your custom plastic tokens or personalized plastic tokens are not only intelligent but also durable, aesthetically pleasing, and delivered on time.

Ready to turn your token-based system into a smart data and engagement platform? Contact our team today for a consultation. Let’s discuss how to embed the future into your next project.

Explore our full range of capabilities and see examples of our work in our custom plastic tokens product showcase.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|