Prototype Injection molding is a versatile manufacturing process used to produce a wide range of plastic parts and products efficiently and cost-effectively. Among the various components involved in injection molding, the sprue plays a critical role in facilitating the flow of molten plastic material into the mold cavity. In this guide, we’ll explore the importance of sprues in injection molding, their design considerations, and best practices for optimizing sprue performance.

What is a Sprue in Injection Molding ?

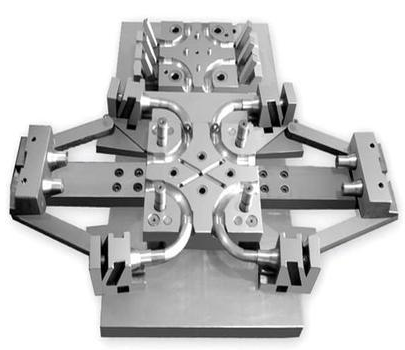

Sprues are the channels through which molten plastic material is introduced into the mold cavity during the injection molding process. They serve as the primary entry points for the material and play a crucial role in ensuring uniform filling of the mold and the formation of high-quality parts. A well-designed sprue system can significantly impact the efficiency, quality, and cost-effectiveness of the injection molding process.

Key Components of Sprue Systems

Sprue Bushing: The sprue bushing, including the hot sprue bushing injection molding, is the component that connects the injection molding machine’s nozzle to the mold’s sprue. It provides a sealed connection to prevent leakage of molten plastic material and facilitates the transfer of material into the mold cavity.

Runner System: The runner system consists of channels that distribute the molten plastic material from the sprue to multiple cavities within the mold. It plays a crucial role in controlling flow dynamics, minimizing pressure drop, and ensuring uniform filling of the mold.

Gates: Injection Molding Gate including sprue break injection molding points, are the points where the molten plastic material enters the mold cavity from the runner system. They come in various shapes and sizes, each offering specific advantages in terms of part quality, cycle time, and production efficiency.

Design Considerations for Sprues

Size and Geometry: The size and geometry of the sprue should be carefully designed to accommodate the required flow rate of the molten plastic material while minimizing pressure drop and turbulence. Factors such as material viscosity, mold configuration, and part geometry should be taken into account during the design process.

Placement: Proper gate location and orientation, considering injection molding sprue sticking issues, are essential for achieving balanced filling and optimal part quality.

Material Selection: The material used for the sprue should be compatible with the molding process and the properties of the plastic material being processed. It should have sufficient strength, heat resistance, and wear resistance to withstand the high pressures and temperatures encountered during injection molding.

Best Practices for Sprue Injection Molding

Maintain Proper Maintenance: Regular maintenance of sprue components, including cleaning, lubrication, and inspection, is essential for ensuring smooth operation and preventing issues such as blockages, leaks, and wear.

Optimize Processing Parameters: Fine-tuning processing parameters such as injection speed, temperature, and pressure can help optimize sprue performance and enhance part quality.

Implement Quality Control Measures: Implementing rigorous quality control measures, including mold testing, in-process inspection, and product testing, can help identify and address sprue-related issues early in the production process, minimizing scrap and rework.

Conclusion

Sprues, including sprue puller injection molding mechanisms, play a critical role in the injection molding process, facilitating the efficient transfer of molten plastic material into the mold cavity and ensuring the production of high-quality parts. By understanding the importance of sprues, adhering to design considerations, and implementing best practices, manufacturers can optimize sprue performance, improve production efficiency, and achieve consistent, reliable results in injection molding operations.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|