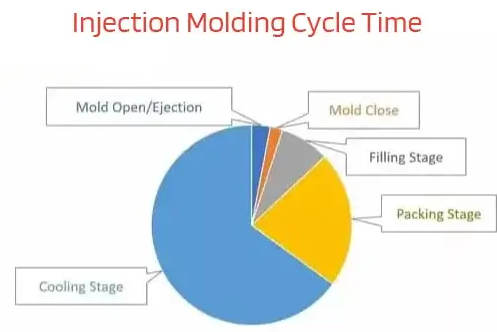

The cycle time in injection molding, which is the total time required to complete one cycle of the injection molding…

2024

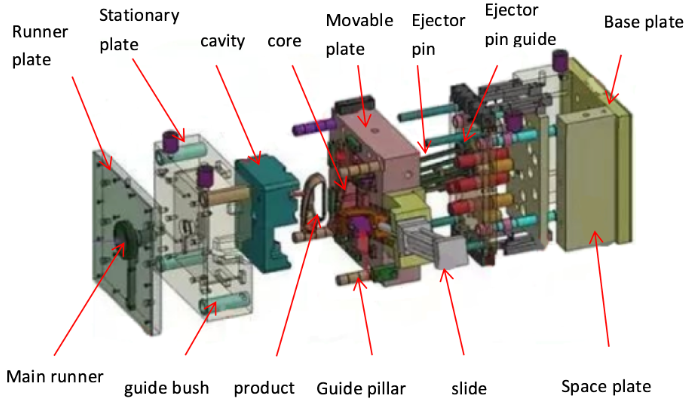

In injection molding, various components and mechanisms are used to connect, align, and secure different parts of the mold to…

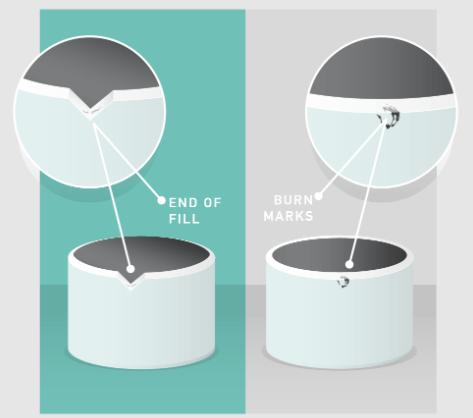

Air bubbles, also known as voids or gas pockets, are common defects in injection molded parts. They can adversely affect…

Plastic injection molds are highly versatile and are used to manufacture a wide range of products. Here are some examples…

Yes, PET (Polyethylene Terephthalate) can be injection molded. PET is a widely used thermoplastic polymer known for its excellent strength,…

In injection molding, the cooling of the part is primarily influenced by the cooling time rather than the hold or…

Warping is a common defect in injection molded parts, where the part bends or twists out of shape after cooling….

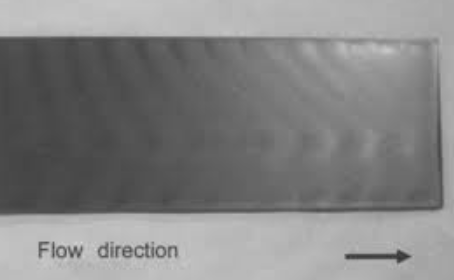

Tiger striping, also known as flow marks or flow lines, is a common surface defect in injection molded parts. These…

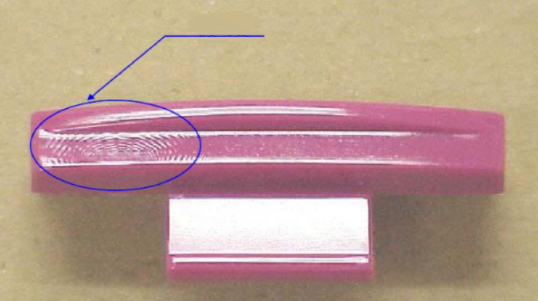

Splay, also known as silver streaks or flow lines, is a common defect in injection molded parts that appears as…

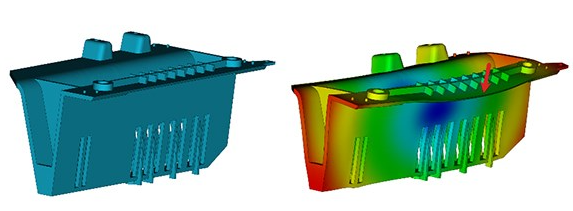

Sinks in injection molding, also known as sink marks, are depressions or dimples on the surface of the molded part….